Aluminum Alloy Door and Window Profiles for Power Amplifier Aluminum Heat Sink Aluminum Profile

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Heat Sink Aluminum Profile for Power Amplifier

Alloy | State | Tensile Strength δbMpa | Non-proportional Stretching Stress(δp0.2Mpa) | Stretching rate (δ%) | Pattern Thickness (mm) | HV | HW |

No Less Than | |||||||

6061 | T4/T6 | 180/265 | 110/245 | 16/8 | - | - | - |

6063 | T5/T6 | 160/205 | 110/180 | 8/8 | 0.8/- | 58/- | 8/- |

6063A | T5/T6 | 200,190/230,220 | 160,150/190,180 | 5,5/5,4 | 0.8,0.8/-,- | 65,65/-,- | 10,10/-,- |

2. Application of Aluminum Heat Sink Aluminum Profile for Power Amplifier

wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors,windows…

3. Feature of Aluminum Heat Sink Aluminum Profile for Power Amplifier

Surface Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Decoration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mochenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

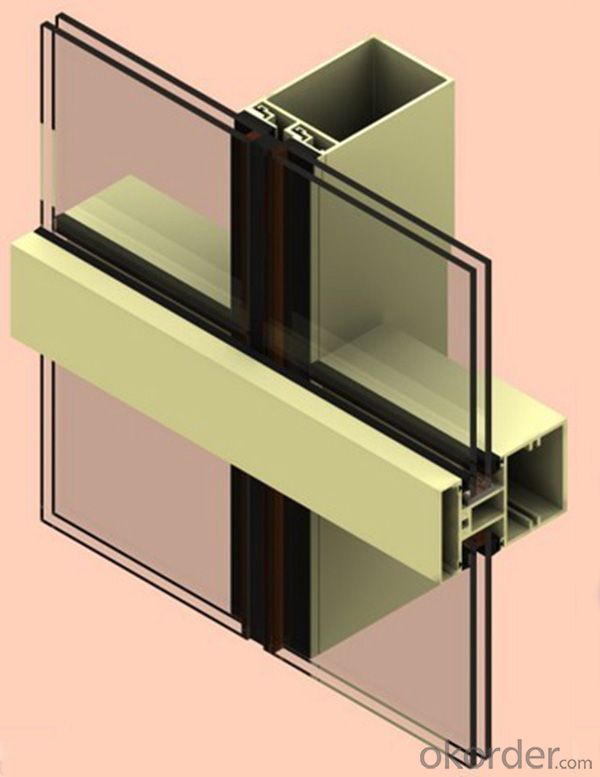

5. Image of Aluminum Heat Sink Aluminum Profile for Power Amplifier

6. Package and shipping of Aluminum Heat Sink Aluminum Profile for Power Amplifier

First, plastic cloth with drying agent inside; Second, Pearl Wool; Third, wooden cases with dry agent, fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

Question 1: What is your MOQ?

We accept one ton per type for an order. But the detail we could negotiate.

Question 2: What is your normal terms of payment?

We always trade with you by T/T. But we also accept the L/C as you require.

Question 3: How many kinds of the surface treatment we can choose?

You could choose different color of powder coated. Anodized of black. matte silver, nature, champagne, bronze color. Mill finished. Wooden finished and printed.etc.

Question 4: Can you supply OEM services?

We offer OEM services for 17 years.

Question 5: How many days for opening the mould?

Normally about 10 days.According to the difficulty of your drawing.

Question 6: Can i choose the package what i want?

Yes, of course. We offer various kinds of package.e.g.PE foam. Shrink film. Wrapping paper.

But we would give you professional suggestion of package.

- Q: Are there any materials for aluminum profiles?

- Aluminum material can be classified as follows:By purpose1. architectural aluminum profiles (divided into two types of doors and windows and curtain wall)2. radiator aluminum profiles.3. general industrial aluminum: mainly used in the manufacture of industrial production, such as automation equipment, covering the skeleton and the custom mold machinery and equipment according to their own requirements, such as assembly line conveyor belt, hoisting machine, glue machine, testing equipment, shelves and so on, the electrical machinery industry and clean room with.4, rail vehicle structure aluminum alloy profile: mainly used for rail vehicle body manufacturing.5, Mount Aluminum profiles, made of aluminum alloy frame, mounted a variety of exhibitions and decorative paintings.

- Q: How do you cut and shape aluminum profiles?

- To cut and shape aluminum profiles, there are several methods you can use depending on the desired outcome and the tools you have available. Here are three common techniques: 1. Cutting with a hacksaw or miter saw: This is the most basic and accessible method. Using a hacksaw or a miter saw with an aluminum cutting blade, mark the desired length on the profile and carefully cut through it. Ensure you have a secure grip on the profile and make slow, steady cuts to avoid excessive vibration or the blade getting stuck. 2. Using a power saw or circular saw: For larger or thicker aluminum profiles, a power saw or circular saw with a specialized aluminum cutting blade will make the job faster and easier. Measure and mark the desired length on the profile, then secure it firmly in place. Using the power saw, slowly and steadily cut through the profile, ensuring you have a firm grip and maintaining control throughout the process. 3. Shaping with a file or grinder: Once the profile is cut to the desired length, you may need to shape or smooth the edges. This can be done using a file or grinder with an aluminum grinding wheel or sanding disc. Carefully work the file or grinder along the edges, shaping or smoothing them as needed. Take care not to apply too much pressure, as aluminum can heat up quickly and may distort or become damaged. Remember to wear appropriate safety gear, such as gloves and eye protection, when working with aluminum profiles. Additionally, it's always a good idea to practice on scrap pieces first to familiarize yourself with the techniques and tools before working on the final product.

- Q: This question asks for a comparison of the benefits and drawbacks of utilizing aluminum profiles within the construction industry.

- <p>Aluminum profiles offer several advantages in construction, including high strength-to-weight ratio, corrosion resistance, and ease of fabrication. They are lightweight, which reduces the load on structures and facilitates easier installation. Their resistance to corrosion means they require less maintenance and have a longer lifespan compared to steel. Additionally, aluminum profiles can be easily cut, bent, and joined, making them versatile for various applications. However, they have some disadvantages, such as lower thermal conductivity, which can be a concern in temperature-sensitive environments. They are also more expensive than some traditional materials like steel. Lastly, aluminum profiles can dent or deform under heavy loads, which may limit their use in certain structural applications.</p>

- Q: What are the strategies to reduce the environmental footprint when utilizing aluminum profiles in construction projects?

- <p>To minimize the environmental impact of using aluminum profiles in construction, consider the following strategies: Use recycled aluminum whenever possible, as it requires significantly less energy to produce than new aluminum. Opt for energy-efficient manufacturing processes and choose suppliers with strong environmental credentials. Design for disassembly and recycling to facilitate the reuse of aluminum profiles at the end of their life. Implement sustainable construction practices that reduce waste and emissions. Finally, educate stakeholders about the importance of sustainable materials and encourage the adoption of eco-friendly practices throughout the construction process.</p>

- Q: Can aluminum profiles be used for outdoor applications?

- Yes, aluminum profiles can be used for outdoor applications. Aluminum is a highly versatile and durable material that is resistant to corrosion, making it suitable for use in outdoor environments. It has excellent weather resistance and can withstand exposure to sunlight, rain, and temperature variations without deteriorating. Aluminum profiles are commonly used in outdoor applications such as construction, architecture, transportation, and outdoor furniture. They offer strength, stability, and longevity, making them a popular choice for outdoor projects. Additionally, aluminum profiles can be finished with protective coatings or anodized to further enhance their resistance to outdoor elements.

- Q: What are the advantages of using aluminum profiles in transportation vehicles?

- There are several advantages of using aluminum profiles in transportation vehicles. Firstly, aluminum is a lightweight material compared to other metals, such as steel. This results in reduced fuel consumption and increased energy efficiency, making it an ideal choice for vehicles that require frequent movement and long distances. The lightweight nature of aluminum also allows for improved maneuverability and handling, enhancing the overall performance of the vehicle. Secondly, aluminum profiles offer excellent corrosion resistance. This is particularly important in transportation vehicles that are frequently exposed to harsh weather conditions and corrosive elements, such as salt and moisture. The corrosion resistance of aluminum ensures the longevity and durability of the vehicle, reducing maintenance and repair costs. Furthermore, aluminum profiles are highly recyclable. The recycling process of aluminum requires significantly less energy compared to the production of primary aluminum. This not only helps in reducing greenhouse gas emissions but also contributes to the overall sustainability of the transportation industry. The recyclability of aluminum also makes it an environmentally friendly choice, aligning with the growing focus on eco-friendly practices. Additionally, aluminum profiles offer great design flexibility. They can be easily extruded into various shapes and sizes, allowing manufacturers to create customized components and structures for transportation vehicles. This flexibility enables the optimization of space and weight distribution, resulting in improved efficiency and functionality. Lastly, aluminum profiles are non-toxic and non-magnetic. This is particularly advantageous in transportation vehicles as it eliminates the risk of interference with sensitive electronic systems and equipment. Aluminum's non-toxic nature also makes it a safe choice for the transportation of food and other sensitive materials. In conclusion, the advantages of using aluminum profiles in transportation vehicles are numerous. Its lightweight, corrosion resistance, recyclability, design flexibility, and non-toxic properties make it an ideal material choice for enhancing fuel efficiency, durability, sustainability, and overall performance in the transportation industry.

- Q: Can aluminum profiles be used in the construction of curtain walls?

- Curtain walls can indeed utilize aluminum profiles. In fact, aluminum stands as one of the most commonly employed materials for curtain wall systems due to its multitude of advantageous properties. Aluminum profiles possess the ideal combination of lightness and strength, making them perfect for constructing large and structurally sound curtain walls. Moreover, aluminum exhibits high resistance to corrosion, guaranteeing the curtain wall's longevity and durability. It also boasts exceptional versatility, easily taking on various shapes and designs to meet specific requirements and creating visually appealing curtain walls. Furthermore, aluminum profiles effortlessly accommodate different components and features, including glazing, insulation, and ventilation systems. This versatility makes them a popular choice for contemporary curtain wall designs. Additionally, using aluminum profiles enables efficient installation and maintenance processes since they can be prefabricated offsite and promptly assembled on-site. All in all, employing aluminum profiles in curtain wall construction offers numerous benefits in terms of strength, durability, versatility, and aesthetics. Consequently, many architects and builders within the construction industry prefer this material.

- Q: This question asks about the various types of fasteners that are used to secure aluminum profiles in construction projects.

- <p>In construction, several types of fasteners are used to secure aluminum profiles. These include: 1. Bolts and Nuts: Commonly used for joining aluminum profiles, they provide a strong and secure connection. 2. Rivets: These are used for permanent connections and are ideal for load-bearing applications. 3. Screws: Self-tapping screws are often used for joining aluminum profiles without the need for pre-drilling. 4. Adhesives: Structural adhesives can be used for bonding aluminum profiles together, providing a strong and durable joint. 5. Clamps and Brackets: These are used to temporarily or permanently secure aluminum profiles in place. 6. Connectors and Brackets: Specifically designed for aluminum profiles, these connectors provide a secure and aesthetically pleasing joint. Each type of fastener has its own advantages and is chosen based on the specific requirements of the construction project.</p>

- Q: Where is the exact location? TwentyBecause I was doing aluminum sales, want to go to the market!Where is the specific market aluminum sales, as long as there is, I have to go around! Say where it is! For example, what area, what road, how many?! Since I went to Chengdu for the first time, please tell me more about it. Thank you!

- Two days ago in the city to find the north gate, Xinshengda profile market have taken a little more, Sammy, the gold house electrical city only one sell Aluminum Alloy, Wanguan electrical didn't go to see, tailor steel city to ask a security guard said little or no 512, no Aluminum Alloy sold, only 512 of the next street there is a Aluminum Alloy sell (416 opposite the hospital). Today I went to Qingbaijiang Fengxiang profile market. Where is the place where the aluminum alloy merchants gathered, the profiles, accessories, processing?...... Goods are available in all varieties。 But the aluminum doors and windows only home balcony with the majority, profile industry, such as steel rack chassis radiator with basically No. This market sells stainless steel materials, businesses are also more. Bus route Liang Jia lane to Qingbaijiang on the car, told the driver to Fengxiang market under the line, and 6 yuan fare, cheaper! Drive away the State Road 108 to Mi Mou Town, Fengxiang market in 108 State Road next great, far away saw. This is the latest information, 2013-9-12

- Q: This question asks about the various methods for connecting aluminum profiles using fasteners.

- <p>There are several ways to join aluminum profiles together using fasteners: 1. Bolts and Nuts: Commonly used for strong and removable connections. 2. Rivets: Provide a permanent connection, suitable for high-stress applications. 3. Screws: Offer a secure and adjustable connection, often used in furniture and construction. 4. Pins: Used for alignment and positioning, often in lighter applications. 5. Adhesives: Can be used for a more aesthetically pleasing joint, though not as strong as mechanical fasteners. 6. Welding: Although not a fastener method, it is a common way to join aluminum profiles for a permanent and strong bond. Each method has its advantages and is chosen based on the specific requirements of the application, such as strength, permanence, and ease of assembly.</p>

Send your message to us

Aluminum Alloy Door and Window Profiles for Power Amplifier Aluminum Heat Sink Aluminum Profile

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords