Aluminized&Galvanizing Sheet Widely Used PPGI/Color Coated Steel Coil/SGCC,SGLCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Widely Used PPGI/Aluminized&Galvanizing Sheet/Color Coated Steel Coil/SGCC,SGLCC

1.Application

Construction | Outside | Workshop, agricultural warehouse, roof panel, wall panel in steel structure in warehouse,corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth |

| Inside | factories exhibition hall,doorcase, light steel roof structure, folding screen, elevator, stairway | |

Electrical appliance | Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker | |

Furniture | Central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf | |

Carrying trade | Exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board | |

Others | Writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment | |

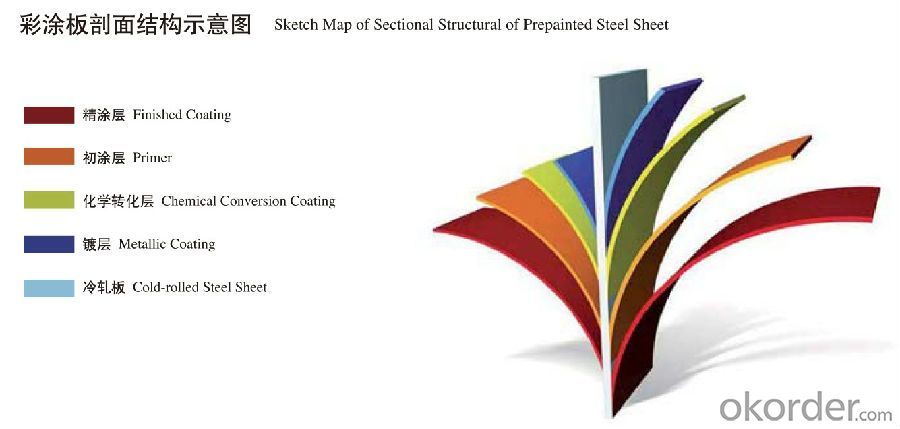

2.Features

With excellent cold-rolling steel strips as base material, it has the advantages of

* Good manufacturing performance

* High impact resistance

* Uniform plating thickness

* High adhesive force

* No peeling after forming

* High corrosion resistance

3.Product Details

*Base Material:Al-Zn Galvanized Steel Coil.SGLCC

*Top Side:15-25 microns

*Back Side:5-8 microns

*Width:700-1250mm

*Thickness: 0.3-1.0mm ,thickness tolerance: +/- 0.02mm

*Al-Zn Coating:30-150g/sq.m

*Spangle:Regular/Zero/Big

*Color:All RAL Color,or be customized

*Coil ID:508mm&610mm

*Delivery time:15-30days after payment

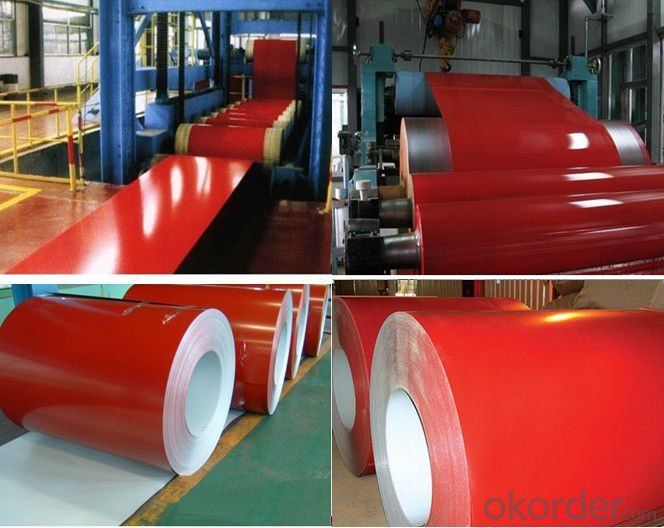

4. Image:

Production

Production Line

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What are the challenges in coil blanking?

- In order to achieve efficient and accurate production, coil blanking, a process used to cut flat metal sheets from coiled stock, must tackle several challenges. Some of the key challenges include: 1. Material variations: Coiled stock can have variations in thickness, width, and surface quality, which can impact the cutting process and result in inconsistent blanks. To ensure consistent quality and dimensional accuracy, it is crucial to carefully select and control the material. 2. Coil set and crossbow: Coiled stock often has inherent shape imperfections like coil set (longitudinal curvature) and crossbow (transverse curvature), which can cause alignment issues during cutting. Minimizing these imperfections requires the use of specialized equipment and techniques, such as straighteners and leveling systems. 3. Coil edge condition: The edges of coiled stock can have burrs, waves, or irregularities, which can affect the quality and precision of the cut blanks. Employing proper edge conditioning techniques, like deburring or edge trimming, is necessary to ensure clean and straight edges. 4. Slitting and shearing forces: The forces exerted during coil blanking can induce stresses and strains in the material, potentially leading to deformation or springback. To minimize these effects and maintain dimensional accuracy, careful consideration of slitting and shearing forces, along with proper tooling design and machine settings, is necessary. 5. Scrap and material waste: Coil blanking can generate significant amounts of scrap material, especially during setup and adjustment phases. Managing scrap and reducing material waste is crucial to optimize production efficiency and minimize costs. Efficient nesting algorithms and real-time monitoring systems can help achieve this. 6. Automation and productivity: Due to market demands, coil blanking often requires high-speed and high-volume production. Enhancing productivity can be achieved through the implementation of automation systems, such as robotic material handling and advanced control systems. However, integrating and synchronizing these components with the cutting process requires careful planning and system integration expertise. Overall, addressing these challenges in coil blanking necessitates proper material selection, advanced equipment, specialized techniques, and efficient process control. By overcoming these challenges, manufacturers can achieve consistent quality, dimensional accuracy, and productivity in coil blanking operations.

- Q: How can defects in steel coils be detected?

- Defects in steel coils can be detected through various non-destructive testing methods such as visual inspection, ultrasonic testing, magnetic particle inspection, eddy current testing, and radiographic testing. These techniques help identify surface cracks, internal flaws, irregularities in thickness, and other defects, ensuring the quality and integrity of the steel coils.

- Q: So here's the deal:I recently bought McCann's Instant Steel-Cut Oatmeal, and I'm wondering about any possible nutritional differences between the instant and regular stove-top. In case you haven't seen it, instant steel-cut comes in individual packets and is cooked only by adding boiling water, the same as instant rolled oatmeal (i.e. Quaker).When I asked about instant vs. stove-top rolled oats, my doctor said there are no significant nutritional differences, but since the main health appeal of steel-cut is the coarse grain, it doesn't seem possible for the finer ground instant to be as nutritious.I can't find much info about this, so any help is appreciated!

- Most people who are used to rolled oats have a very hard time adjusting to steel cut oats that are cooked only 30 minutes. For many, it's not much different than eating them raw. (Raw, soaked oats is called cram. Having to eat uncooked oats, as only the poorest would do, gives us the expression 'to cram it down your throat'.) Better still is to cook them thoroughly at night then reheat portions for breakfast if you're in a hurry. They'll keep about five days at a time under refrigeration. Any small nutritional loss from longer cooking is more than compensated by the better digestibility of well-cooked oats. That is, the nutrition is wasted if the oats pass undigested through the body. For most of us, that would happen. Indeed, we are not cows. Neither are we horses. People need to cook their oats.

- Q: How are steel coils processed and treated?

- To ensure the quality and suitability of steel coils for different applications, they undergo a series of steps and treatments. Initially, the coil is uncoiled by removing its protective wrapping and unwinding it. Any defects like cracks or uneven surfaces are then inspected. Next, the coil is cleaned to eliminate dirt, oil, and rust using chemical agents and mechanical scrubbing. After cleaning, it is rinsed and dried to prevent corrosion caused by residual moisture. Once cleaned, the steel coil may be treated based on its intended use. One common treatment is pickling, where the coil is immersed in an acidic solution to remove impurities and scale. This improves the surface finish and prepares the steel for further processing. After pickling, the coil can undergo cold rolling, which reduces its thickness and improves dimensional accuracy. This is done by passing the steel through a series of rollers at room temperature, gradually decreasing thickness and increasing strength. It also improves the surface finish. In some cases, the coil may undergo additional heat treatments like annealing or tempering. Annealing involves heating the coil to a specific temperature and slowly cooling it to relieve internal stresses and improve mechanical properties. Tempering, on the other hand, involves reheating the coil to a lower temperature and rapidly cooling it to enhance strength and toughness. Once the desired processing and treatments are completed, the steel coil may be coated or painted for added protection against corrosion or to enhance its appearance. Coating processes can include hot-dip galvanizing, electroplating, or applying organic coatings like paint or powder coatings. Finally, the processed and treated steel coils are cut into specific sizes or shapes according to customer requirements. This can be done using cutting methods such as shearing, slitting, or sawing. Overall, the processing and treatment of steel coils involve cleaning, pickling, rolling, heat treatment, coating, and cutting processes. These steps are carefully carried out to ensure the quality, strength, and suitability of the steel for its intended applications.

- Q: How are steel coils used in the food processing industry?

- Steel coils are commonly used in the food processing industry for various purposes. One primary application is in the production of food packaging materials, such as cans and containers. These coils are transformed into thin sheets or strips that are then formed into the desired shape and size for packaging different food products. Steel coils are also utilized in the manufacturing of equipment and machinery used in food processing plants. This includes machines like conveyors, mixers, and slicers, which are crucial for the efficient and automated processing of food products. The durability and strength of steel make it an ideal material for these types of equipment, as it can withstand heavy usage and maintain its structural integrity. In addition, steel coils are used in the construction of storage and refrigeration facilities within the food processing industry. These coils are transformed into durable and insulated panels that are used to create walls and ceilings of cold rooms, freezers, and warehouses. The excellent thermal properties of steel help maintain the desired temperature and prevent spoilage of perishable food items. Furthermore, steel coils are employed in the production of cooking and baking equipment, such as ovens and grills. These coils are transformed into heating elements that provide consistent and efficient heat distribution during the food preparation process. This ensures that food is cooked or baked evenly, resulting in high-quality and delicious products. Overall, steel coils play a vital role in the food processing industry by providing the necessary materials for packaging, equipment, and infrastructure. Their strength, durability, and thermal properties make them a preferred choice for various applications within this industry, ensuring the production of safe and high-quality food products.

- Q: I bought a Remington 870 super mag last fall and wanted to to switch to non-tox steel loads. The gun came with a modified rem choke. I know that not all chokes are qualified to handle steel. It doesn't say anywhere on the choke no steel I was just wondering if anyone out there knew for sure that those chokes that the guns come with won't get damaged be steel.

- Remington 870 Chokes

- Q: Can steel coils be coated with abrasion-resistant materials?

- Yes, steel coils can be coated with abrasion-resistant materials. These materials are applied to the surface of the steel coils to enhance their resistance to wear and tear caused by friction, impact, or scratching. The abrasion-resistant coating provides a protective layer that helps prolong the lifespan and durability of the steel coils.

- Q: How do we use steel ?plesase answer, its for homework xxx

- This Site Might Help You. RE: How do we use steel ? How do we use steel ? plesase answer, its for homework xxx

- Q: How are steel coils used in the manufacturing of power generation equipment?

- Steel coils are used in the manufacturing of power generation equipment as they are shaped and formed into various components such as turbine blades, casings, and structural supports. The strength and durability of steel make it suitable for withstanding high temperatures and pressures, ensuring the reliability and longevity of the equipment. Additionally, steel coils are often used in the production of electrical transformers and generator cores, providing a magnetic circuit that efficiently converts mechanical energy into electrical energy.

- Q: Corten steel tends to overheat in hot environments? (for example copper heats up under the sun)

- Bill summed it up pretty quick and provided a link. For some reason you are focusing on the copper content when it really is insignificant in the overall picture of the sun hitting its surface. If you could elaborate more, maybe we could offer a better answer.

Send your message to us

Aluminized&Galvanizing Sheet Widely Used PPGI/Color Coated Steel Coil/SGCC,SGLCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords