Berger Aluminum Coil - Aluminium Profiles for Window, Door, and Heat Sink Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminium Profiles Window and Door Profiles Heat Sink Profile Description:

Aluminium Profiles Window and Door Profiles Heat Sink Profile(also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium Profiles Window and Door Profiles Heat Sink Profile:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

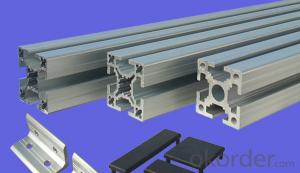

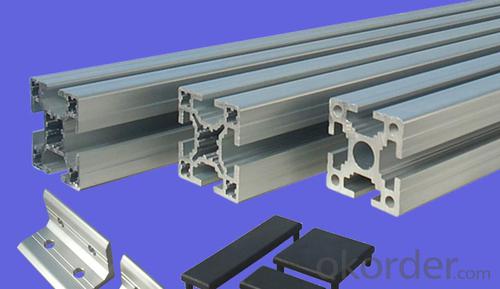

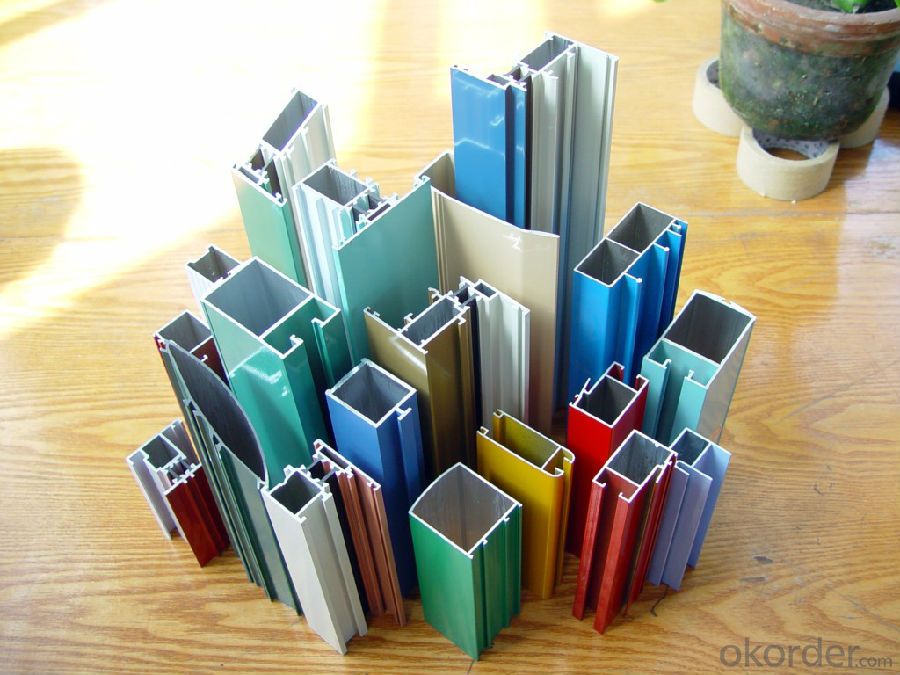

3.Aluminium Profiles Window and Door Profiles Heat Sink Profile Images:

4.Aluminium Profiles Window and Door Profiles Heat Sink Profile Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What is the difference between pre-painted and natural aluminum coils?

- Pre-painted aluminum coils are coated with a layer of paint or protective finish before they are used, offering enhanced durability and aesthetics. On the other hand, natural aluminum coils are left untreated and retain their original metallic appearance. The main difference lies in their appearance, level of protection, and resistance to corrosion.

- Q: aluminum welding

- Impossible. You need a TIG welder with AC and high frequency. Although you CAN use solid wire MIG with 100% argon shield gas, this is not a job for amateurs. MIG welding aluminum requires professional-grade equipment and several years experience with welding.

- Q: What is the minimum thickness available for aluminum coils?

- The specific requirements of the application can cause variations in the minimum thickness available for aluminum coils. Typically, aluminum coils can have a minimum thickness of approximately 0.006 inches or 0.15 millimeters. It is crucial to consider that different industries or uses may impose distinct minimum thickness demands. Therefore, it is advisable to seek guidance from a manufacturer or supplier to ascertain the suitable thickness for a particular application.

- Q: Can aluminum coils be used in solar energy systems?

- Yes, aluminum coils can be used in solar energy systems. Aluminum is a commonly used material in the construction of solar panels and solar energy systems due to its excellent properties. Aluminum coils are lightweight, durable, and have excellent thermal conductivity, making them ideal for transferring heat away from the solar cells. Additionally, aluminum is resistant to corrosion, which is crucial for outdoor applications where solar panels are exposed to various weather conditions. The use of aluminum coils in solar energy systems helps improve the overall efficiency and lifespan of the panels, contributing to the effectiveness and sustainability of solar energy generation.

- Q: I heard that clay pots and aluminum cans are great caves for my fish to breed in but will the can rust???

- Aluminum will not rust. Only iron rusts. Because steel has iron in it, steel can rust.

- Q: Can aluminum coils be used in the production of aluminum louvers?

- Yes, aluminum coils can be used in the production of aluminum louvers. Aluminum coils are a common raw material used in various industries, including the manufacturing of louvers. Aluminum coils are typically processed and formed into the shape and design required for louvers, providing the necessary strength and durability. The use of aluminum coils also allows for flexibility in design and customization of louvers to meet specific requirements. Additionally, aluminum is a lightweight and corrosion-resistant material, making it suitable for louvers that may be exposed to outdoor conditions. Overall, aluminum coils are widely used in the production of aluminum louvers due to their numerous advantages and suitability for this application.

- Q: What are the different coil embossing options available for aluminum coils?

- Aluminum coils offer a range of coil embossing options, each with its own unique textures and patterns. Stucco, diamond, and 3-bar embossing are some common options for aluminum coils. Stucco embossing creates a textured pattern similar to a stucco wall, making it popular for its ability to hide imperfections and provide an attractive finish. It finds applications in industries like construction and automotive. Diamond embossing, on the other hand, creates a diamond-shaped pattern that enhances the coil's strength and durability. It is commonly used in flooring, roofing, and decorative applications. 3-bar embossing adds three parallel lines to the aluminum coil's surface, providing a visually appealing look and enhanced traction. This makes it ideal for applications requiring slip resistance, such as ramps and walkways. In addition to these options, there are other embossing patterns available, such as wood grain, hammer tone, and leather grain embossing. These patterns mimic natural materials and are often used in interior design and architecture. The choice of embossing option depends on specific requirements and desired aesthetics. Manufacturers and customers can select the most suitable pattern based on factors like durability, texture, slip resistance, and overall design intent.

- Q: Who knows about how much money can be sold in a three metre high similar aluminum door?

- How wide is it, mainly to see the door you have multiple components, scrap is generally about 10 yuan a kilogram!

- Q: How do aluminum coils perform in high humidity environments?

- Due to its inherent resistance to corrosion, aluminum coils excel in high humidity environments. Unlike metals like iron or steel, aluminum does not rust when exposed to moisture. Thus, it is an ideal option for applications where high humidity is a worry, such as air conditioning systems or refrigeration units. The corrosion resistance of aluminum primarily stems from the creation of a thin layer of aluminum oxide on its surface when it comes into contact with oxygen. This oxide layer acts as a protective barrier against further oxidation, safeguarding the metal from deterioration even in humid conditions. Furthermore, the lightweight nature of aluminum enables superior heat transfer and energy efficiency in cooling systems. This characteristic makes aluminum coils a favored choice as heat exchangers, efficiently transferring heat from the air or fluid flowing through them. Additionally, aluminum coils are commonly coated with a protective layer or treated with a corrosion-resistant coating to further enhance their performance in high humidity environments. These coatings offer an additional layer of defense against moisture and other corrosive elements, ensuring the durability and dependability of the coils. In conclusion, aluminum coils are highly suitable for high humidity environments due to their corrosion resistance and efficient heat transfer properties. The combination of these factors makes them a reliable option for various applications where moisture is a concern.

- Q: What are the weight and thickness options for aluminum coils?

- The weight and thickness options for aluminum coils can vary depending on the specific requirements and applications. Aluminum coils are available in a wide range of weights and thicknesses to cater to various industries and needs. In terms of weight, aluminum coils can be found in different options such as light gauge, standard gauge, and heavy gauge. Light gauge aluminum coils typically range from 0.006 to 0.025 inches in thickness and are commonly used in industries that require lightweight materials such as packaging, electronics, and automotive components. Standard gauge aluminum coils are slightly thicker, ranging from 0.026 to 0.063 inches, and are often used in construction, roofing, and transportation applications. Heavy gauge aluminum coils are the thickest option, typically ranging from 0.064 inches and above, and are commonly utilized in heavy-duty applications such as aerospace, marine, and industrial equipment manufacturing. Regarding thickness, aluminum coils come in various options as well. The thickness is typically measured in inches or millimeters, and the range can vary from as thin as 0.006 inches (0.15 mm) to as thick as 0.25 inches (6.35 mm) or even higher for specific applications. The appropriate thickness of the aluminum coil depends on the intended use and the desired structural strength or flexibility required. It is important to note that these weight and thickness options may vary depending on the manufacturer and the specific aluminum alloy used. It is always recommended to consult with the manufacturer or supplier to determine the most suitable weight and thickness options for your specific application.

Send your message to us

Berger Aluminum Coil - Aluminium Profiles for Window, Door, and Heat Sink Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords