Copper Aluminum Coil Prices for Building Curtain Wall Shutter Aluminum Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Aluminum Profiles for Building Curtain Wall Shutter Description

Aluminum Profiles for Building Curtain Wall Shutter is one semi-finished aluminium material. The alloy AA6063 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Aluminum Profiles for Building Curtain Wall Shutter

Aluminum Profiles for Building Curtain Wall Shutter | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Aluminum Profiles for Building Curtain Wall Shutter

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Aluminum Profiles for Building Curtain Wall Shutter

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Aluminum Profiles for Building Curtain Wall Shutter

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

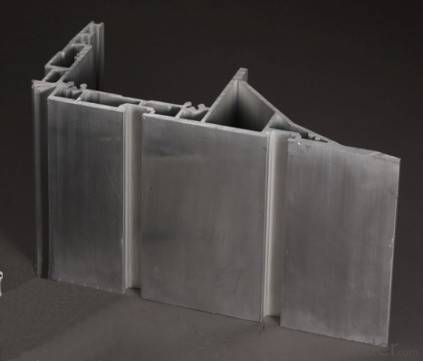

6. Image of Aluminum Profiles for Building Curtain Wall Shutter

7. Package and shipping of Aluminum Profiles for Building Curtain Wall Shutter

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How are aluminum coils joined or welded?

- Aluminum coils can be joined or welded using various methods depending on the specific application and desired outcome. Some common methods include: 1. Mechanical fastening: This involves using bolts, screws, or rivets to physically fasten the aluminum coils together. Mechanical fastening is a simple and cost-effective method, suitable for joining thin coils or for temporary connections. 2. Adhesive bonding: Adhesive bonding involves using specialized adhesives to bond aluminum coils together. This method provides a strong and durable joint, with the added advantage of distributing stress evenly across the entire bond area. Adhesive bonding is commonly used in applications where aesthetics, weight reduction, or vibration dampening are important considerations. 3. Resistance welding: Resistance welding utilizes an electric current to generate heat and pressure at the joint, effectively welding the aluminum coils together. This method is particularly suitable for high-speed production lines and can provide a strong and reliable joint. However, it requires specialized equipment and is not suitable for all types of aluminum alloys. 4. Laser welding: Laser welding is a precise and efficient method that uses a laser beam to melt and join the aluminum coils. This technique allows for precise control of heat input, resulting in minimal distortion and excellent weld quality. Laser welding is commonly used in industries where high precision and aesthetic appearance are crucial, such as automotive and aerospace. 5. Friction stir welding: Friction stir welding is a solid-state joining process that uses a rotating tool to generate heat and friction, effectively welding the aluminum coils together without melting the material. This method produces strong and high-quality welds with minimal distortion and no need for additional filler material. Friction stir welding is commonly used in industries where excellent mechanical properties and high productivity are required, such as shipbuilding and railway construction. Overall, the choice of joining or welding method for aluminum coils depends on factors such as the desired joint strength, application requirements, production volume, and available equipment and expertise.

- Q: Are aluminum coils compatible with different welding methods?

- Yes, aluminum coils are compatible with different welding methods such as MIG (Metal Inert Gas) welding, TIG (Tungsten Inert Gas) welding, and even resistance spot welding. These methods can be used to join aluminum coils effectively and efficiently.

- Q: What precautions should be taken to ensure the safe and efficient transportation of aluminum coils?

- <p>The best way to handle aluminum coil during transportation involves using proper lifting equipment, ensuring secure strapping, and maintaining a stable and dry environment. Use slings or lifting beams specifically designed for metal coils to prevent damage. Ensure the coil is strapped tightly to prevent shifting during transit. Keep the coils covered to protect from moisture and dirt. Always follow the manufacturer's guidelines for weight limits and handling procedures.</p>

- Q: How are aluminum coils protected against oxidation during storage?

- Aluminum coils are protected against oxidation during storage through a variety of methods. One common method is applying a protective coating on the surface of the coils. This coating acts as a barrier, preventing oxygen from coming into contact with the aluminum and causing oxidation. The coating can be a thin layer of oil or a special protective film. Another method is storing the coils in a controlled environment with low humidity. Moisture in the air can accelerate the oxidation process, so by keeping the coils in a dry environment, the risk of oxidation is reduced. Additionally, aluminum coils can be stored in airtight packaging, such as plastic wraps or vacuum-sealed bags. This further minimizes the exposure to oxygen, preventing oxidation. It is also important to handle the coils with care during storage to avoid any damage that could potentially expose the aluminum to the air. Proper packaging and stacking techniques are crucial to ensure the coils remain protected. Overall, a combination of protective coatings, controlled environments, and proper handling techniques are employed to safeguard aluminum coils against oxidation during storage.

- Q: Can aluminum coils be recycled?

- Yes, aluminum coils can be recycled. Aluminum is a highly recyclable material and can be melted down and reused multiple times without losing its properties. Recycling aluminum coils helps to conserve natural resources and reduce energy consumption.

- Q: What maintenance is required for aluminum coils?

- Maintenance for aluminum coils typically includes regular cleaning and inspection to ensure efficient performance and longevity. Here are some specific maintenance requirements for aluminum coils: 1. Cleaning: Regularly clean the aluminum coils to remove dirt, dust, and debris that can accumulate on the surface. Use a soft brush or a vacuum cleaner with a brush attachment to gently remove any loose particles. Avoid using abrasive cleaners or brushes that can scratch or damage the surface of the aluminum. 2. Inspection: Periodically inspect the aluminum coils for signs of damage or wear. Check for any bent or dented fins, which can restrict airflow and reduce the coils' efficiency. Look for signs of corrosion, such as discoloration or pitting, as this can affect the coils' performance and lifespan. 3. Coil Protection: Apply a protective coating or sealant to the aluminum coils to prevent corrosion and damage from exposure to moisture, chemicals, or harsh environmental conditions. This can help prolong the life of the coils and maintain their performance. 4. Lubrication: If your aluminum coils are part of a mechanical system, such as an HVAC unit, ensure that any moving parts are properly lubricated. This can help reduce friction and wear on the coils, improving their efficiency and preventing premature failure. 5. Professional Maintenance: Consider scheduling regular professional maintenance for your aluminum coils, especially if they are part of a larger system. HVAC technicians or specialized coil cleaning services can provide a thorough inspection, cleaning, and maintenance to ensure optimal performance and identify any potential issues early on. By following these maintenance practices, you can help extend the lifespan of your aluminum coils, improve their efficiency, and prevent costly repairs or replacements.

- Q: Can a digital caliper be utilized to accurately measure the diameter of an aluminum coil?

- <p>Yes, you can use a digital caliper to measure the diameter of an aluminum coil accurately. Digital calipers are precise measuring tools, often accurate to 0.001 inches or 0.02mm, which is suitable for measuring the diameter of various objects, including aluminum coils. Ensure the caliper is zeroed before use and that the coil's surface is clean and flat where the measurement is taken to get accurate readings.</p>

- Q: What are the common surface preparation methods for aluminum coils?

- Common surface preparation methods for aluminum coils include cleaning, degreasing, and etching. Cleaning is typically the first step in the surface preparation process for aluminum coils. This involves removing any dirt, dust, or other contaminants from the surface. Cleaning can be done using a variety of methods, such as using solvents, alkaline cleaners, or mechanical cleaning techniques like brushing or scrubbing. Degreasing is another important step in preparing aluminum coils. This helps to remove any oils or greases that may be present on the surface. Degreasing can be done using solvents or alkaline cleaners specifically designed for this purpose. It is essential to thoroughly remove any grease or oils, as they can interfere with subsequent treatments and coatings. Etching is often performed on aluminum coils to create a roughened surface, which improves adhesion for subsequent coatings or treatments. Etching can be done using chemical etchants or through mechanical methods such as sandblasting. The choice of etching method depends on the specific requirements of the application and the desired surface finish. After surface preparation, additional treatments may be applied to aluminum coils, such as conversion coatings or anodizing, to enhance corrosion resistance or improve surface properties. These treatments help to protect the aluminum surface and provide a base for further finishes or coatings. Overall, proper surface preparation is crucial for achieving good adhesion, corrosion resistance, and overall performance of aluminum coils in various applications. It ensures that the surface is clean, free from contaminants, and properly prepared for subsequent treatments or coatings.

- Q: Can aluminum coils be customized or fabricated into specific shapes?

- Indeed, it is possible to customize or fabricate aluminum coils into desired shapes. Aluminum possesses remarkable formability and can be effortlessly shaped through diverse fabrication techniques such as rolling, bending, stamping, and extrusion. By employing these processes, aluminum coils can be converted into specific forms like sheets, plates, tubes, and profiles to cater to the unique demands of different applications. Moreover, aluminum can also be welded, joined, or cut to further tailor its shape and dimensions. The adaptability of aluminum coils in terms of customization renders them highly favored across various industries, including automotive, aerospace, construction, and manufacturing.

- Q: How is Aluminum formed??Thanks!!

- okorder nice.

Send your message to us

Copper Aluminum Coil Prices for Building Curtain Wall Shutter Aluminum Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords