024 96 Wide Aluminum Sheet Coil Houston - Aluminium Prepainted Coil Hot Demanded 3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Prepainted Coil Hot Demanded 3003:

Aluminium coil/sheet are of a wide range of specifications, and they are widely used in:Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...Advertisement: display platforms, signboards, fascia, shop fronts...

Main Features of Aluminium Prepainted Coil Demanded 3003 :

1) High gloss

2) High flexibility

3) Impact resistance

4) Excellent weather-proof durability

5) Anti-ultraviolet

6) High erosion resistance

7) Stable color and gloss

8) Good mechanical processing performance

9) Abrasion resistance

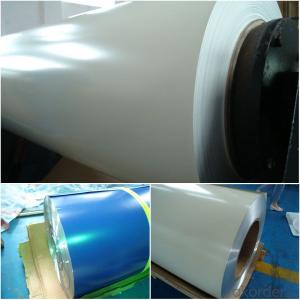

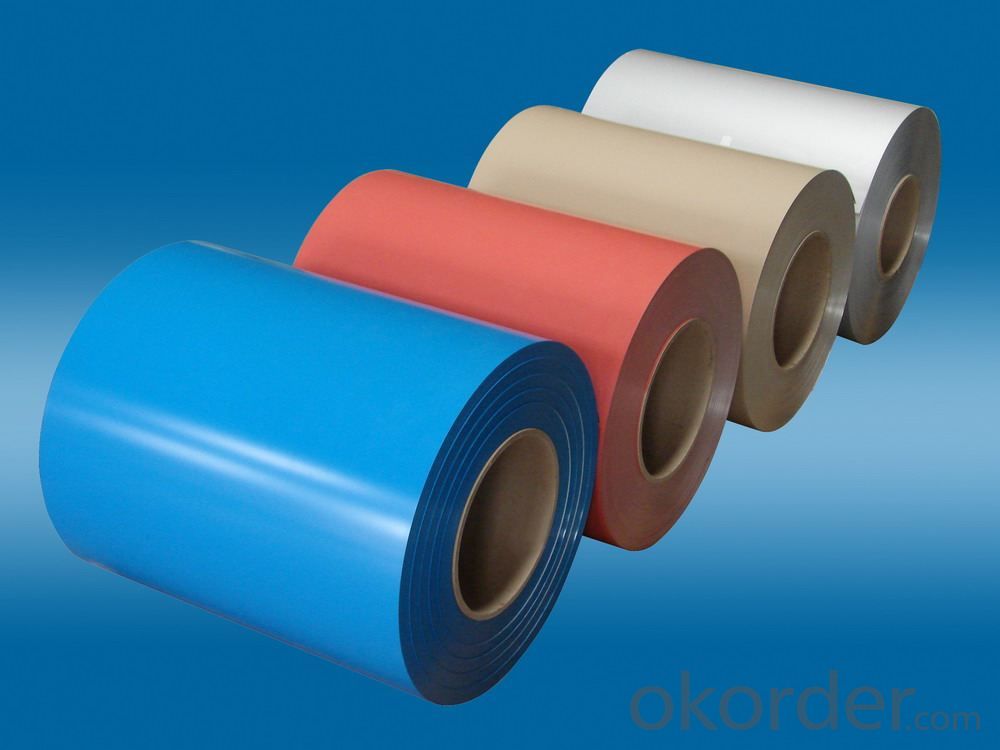

Image of Aluminium Prepainted Coil Demanded 3003:

Specifications of Aluminium Prepainted Coil Demanded 3003:

Alloy | A1100,A3003, A8011 etc |

Temper | H16,H18,H26 |

Thickness | 0.02-3.0mm |

Width | Standard width:1200 1240mm |

30mm-1500mm | |

Diameter | Outside dia:1200mm\1000mm\1240 |

Interior dia: 405mm,505mm | |

Weight | 1.5T/coil,2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, |

Surface | Color coated, Embossed, mill finish, |

Color | As to RAL |

Gloss | 10 - 90%(EN ISO-2813:1994) |

Coating Thickness | P E : more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ of Aluminium Coil:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Can aluminum coils be used in the production of aluminum composite doors?

- Yes, aluminum coils can be used in the production of aluminum composite doors. Aluminum coils are often used as the primary material for manufacturing aluminum composite doors due to their durability, lightweight nature, and corrosion resistance. These coils are typically processed and shaped into different components of the door, such as panels, frames, and profiles, to create a strong and aesthetically appealing final product.

- Q: I need to lay down two 3 welds on some 1/8 aluminum but my welder is not set up for it. could i just out fit my welder with aluminum wire without buying the spool gun and get the same results? or maybe I should just get a welding shop to do it for me?

- Hi. You need a spherical tip on, say, a mig welder to be successful when welding aluminum. Spreads out the heat better.

- Q: I had a physics exams today and it was asking whether or not a shiny surface aluminium blanket was suitable to keep the sleeper warm. I put that because it's a conductor of electricitiy, heat loss will be greater so it wont be suitable for keeping him warm. On the other hand, some other people said that because it had a shiny surface, thus a good reflector of heat, it would be suitable for keeping him warm. Are both arguments correct?

- Metals are reflective for the comparable reason that they habit electrical energy. The steel has an excellent number of electrons that are very loosely guaranteed to the atoms; they are in a position to leap from one atom to a distinctive very quite. that's virtually like a sea of electrons. Electrons soak up photons of sunshine then re-emit them in random instructions, that's stated as scattering. you are able to think of that if the electrons emit the photons in random instructions then the floor could be boring white, no longer vivid, yet in reality so long as a results of fact the floor irregularities on the steel are smaller than a wavelength of sunshine each and all of the photons entering into extraordinary instructions cancel one yet another out, in simple terms leaving those that leap off on the comparable attitude they arrived at - mirrored photograph in different words. Metals are literally sparkling. you are able to locate that frustrating to have self belief yet once you're finding at an liquid crystal reveal reveal screen you're finding by using a layer of steel now - it varieties electric powered circuits on the returned of the glass reveal. Any cloth that reflects easy additionally transmits it. while the electrons are greater efficient at interacting with the photons of sunshine the fabric is greater reflective, as in a steel; while fewer electrons are interacting with the easy the fabric is greater transmissive, like glass or water. yet observe that cup and water the two mirror easy besides as transmit it.

- Q: Describe the various uses of aluminum coils in the manufacturing industry.

- <p>Aluminum coils are widely used in manufacturing due to their lightweight, corrosion resistance, and strength. They are utilized in the production of various products such as automotive parts, aerospace components, and construction materials. Aluminum coils are also employed in the manufacturing of electrical wiring, heat exchangers, and packaging materials. Additionally, they are used in the production of cans and foils for food and beverage industries. Their versatility makes aluminum coils an essential material in many manufacturing processes.</p>

- Q: Are there any limitations to the minimum coil length of aluminum coils?

- The minimum coil length of aluminum coils has certain limitations. These limitations are influenced by factors such as the manufacturing process, equipment capabilities, and the intended use of the coils. One limitation arises from the size and capacity of the manufacturing equipment. To ensure smooth operation and prevent damage during manufacturing, most coil production lines have a minimum length requirement. If the coil is too short, it may not be processed or handled properly by the equipment, resulting in production issues or defects. Another limitation is determined by the intended use of the coils. Certain applications may demand a minimum coil length to meet specific requirements or ensure optimal performance. For instance, industries like construction or automotive often utilize coils to create components or structures with precise length specifications. In such cases, the minimum coil length is determined by the end product's specifications. Furthermore, handling and transportation considerations also impact the determination of the minimum coil length. Coils that are too short might pose challenges in terms of handling, transportation, and storage, making them impractical or cost-inefficient. In conclusion, the minimum coil length of aluminum coils is constrained by manufacturing equipment capabilities, intended use, and practicality in terms of handling and transportation. These limitations guarantee efficient production processes, adherence to product specifications, and practicality within the overall supply chain.

- Q: I heard that one pound of aluminum pop tabs are worth more then a pound of aluminum pop cans. Is this true? Thank you.

- I Think So Because clean aluminum is easier to handle because they don't have to wash it like unclean aluminum.

- Q: How do aluminum coils compare to steel coils in terms of strength?

- Aluminum coils and steel coils differ significantly in terms of strength. Steel coils are generally stronger and more durable than aluminum coils. Steel is known for its high tensile strength and ability to withstand heavy loads, making it a preferred choice for applications that require high strength and durability. On the other hand, aluminum coils have a lower strength compared to steel. Aluminum is a lightweight metal with a lower tensile strength, which means it may not be as resistant to heavy loads or stress as steel coils. However, aluminum coils have other favorable properties such as excellent corrosion resistance and high thermal conductivity. The choice between aluminum and steel coils depends on the specific application and requirements. If strength and durability are the primary concerns, steel coils are usually the better option. However, if weight reduction, corrosion resistance, or thermal conductivity are more important, aluminum coils might be the preferred choice.

- Q: Can aluminum coils be used for food storage containers?

- Yes, aluminum coils can be used for food storage containers. Aluminum is a popular choice for food storage containers due to its many beneficial properties. It is lightweight, durable, and has excellent thermal conductivity, meaning it can evenly distribute heat for efficient cooking or cooling. Additionally, aluminum is non-toxic, odorless, and resistant to corrosion, making it a safe option for storing food. It also provides an effective barrier against light, moisture, and oxygen, which helps to preserve the freshness and quality of the stored food. Overall, aluminum coils can be a reliable and practical choice for food storage containers.

- Q: This question asks about the impact of aluminum coils on food quality, considering possible effects on taste, safety, and preservation.

- <p>Aluminum coils, when used in cooking or food packaging, can potentially affect the quality of food. If aluminum leaches into the food, it may alter the taste and could pose health risks due to aluminum's neurotoxic properties. However, modern food-grade aluminum coils are coated or anodized to prevent such leaching, ensuring food safety. They are also used in heat transfer for cooking, which can improve the efficiency and evenness of cooking, thus enhancing food quality. It's crucial to use high-quality, food-safe aluminum coils to avoid any negative impact on food quality and safety.</p>

- Q: How do aluminum coils compare to other metal coils?

- Aluminum coils are generally lighter, more corrosion-resistant, and have better thermal conductivity compared to other metal coils. They are also easier to shape and mold, making them a popular choice in various industries including automotive, aerospace, and HVAC.

Send your message to us

024 96 Wide Aluminum Sheet Coil Houston - Aluminium Prepainted Coil Hot Demanded 3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords