High Quality Coil Aluminum Stock - Aluminium Pre-Painted Coil/Sheet Serie 3

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

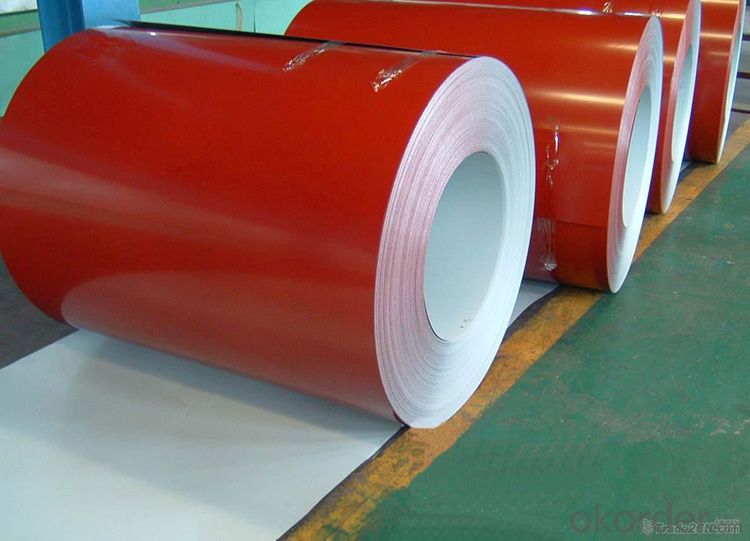

Structure of Aluminium Aluminium Pre-painted Coil/Sheet Serie 3 High Qulity Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Pre-painted Coil/Sheet Serie 3 High Qulity:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of theAluminium Pre-painted Coil/Sheet Serie 3 High Qulity:

Aluminium Pre-painted Coil/Sheet Serie 3 High Qulity Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium Pre-painted Coil/Sheet Serie 3 High Qulity:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Can aluminum coils be used in electrical applications?

- Indeed, aluminum coils possess the capability for utilization in electrical applications. Its abundance in electrical wiring is attributable to its cost-effectiveness and superior conductivity in comparison to copper. Transformers, motors, generators, and other electrical apparatuses commonly rely on aluminum coils. Nevertheless, it is essential to acknowledge that copper surpasses aluminum in terms of electrical conductivity, necessitating the use of larger aluminum coils to attain equivalent levels of conductivity. Moreover, the implementation of specialized insulation and connectors becomes imperative for aluminum coils to prevent corrosion and guarantee appropriate electrical connections.

- Q: Are aluminum coils compatible with other materials?

- Yes, aluminum coils are compatible with other materials. Aluminum is a versatile and widely used material that can be easily integrated with various other materials in different applications. For example, aluminum coils can be used in conjunction with copper tubing in air conditioning and refrigeration systems to enhance heat transfer efficiency. Additionally, aluminum coils can be coated or laminated with other materials such as polymers or paints to provide additional protection against corrosion, improve aesthetics, or enhance specific performance characteristics. Therefore, aluminum coils offer compatibility with a range of materials, making them suitable for diverse applications in industries such as construction, automotive, aerospace, and more.

- Q: What are the tensile strength properties of aluminum coils?

- The tensile strength properties of aluminum coils can vary depending on the specific alloy and temper of the aluminum. Generally, aluminum has a good tensile strength, ranging from 70 to 700 MPa (megapascals). The specific tensile strength of aluminum coils can be determined through material testing and analysis.

- Q: What are the standard widths of aluminum coils?

- The specific industry and application play a role in determining the varying standard widths of aluminum coils. Generally, aluminum coils come in widths ranging from 12 inches (30.48 cm) to 60 inches (152.4 cm). These widely accepted widths are commonly utilized in construction, transportation, and manufacturing sectors. It is worth mentioning that customized widths are also readily accessible to meet specific project needs in the market.

- Q: What are the common surface repair methods for aluminum coils?

- Aluminum coils can be repaired using various surface repair methods. Mechanical repair is one of the most commonly used techniques. It involves sanding or grinding the affected area to eliminate corrosion and imperfections. Following this, a filler or putty is applied to even out the surface and create a seamless repair. Once the filler has dried, the repaired section can be sanded again to achieve a smooth finish. Chemical repair is another popular method. It entails utilizing specialized chemicals to eliminate oxidation or corrosion from the aluminum coil's surface. This is done by directly applying the chemical to the damaged area and allowing it to react with the surface, breaking down any corrosion or oxidation. After the chemical has completed its task, the coil is rinsed, dried, and any remaining imperfections are addressed using mechanical repair methods. Heat repair methods can also be employed in certain cases. This involves using a heat gun or torch to heat the damaged portion, making the aluminum soft and malleable. Once heated, the metal can be reshaped or manipulated to remove dents or deformations. Careful control of the heat is necessary to prevent further damage to the coil. Lastly, anodizing is a commonly used surface repair method. It involves applying a protective coating to the coil's surface, which not only repairs any damage but also provides additional protection against future corrosion or oxidation. Anodizing is often chosen for more extensive repairs or when the coil will be exposed to harsh environments. The choice of surface repair method for aluminum coils depends on the extent of the damage and the desired outcome. It is advisable to consult with a professional or follow the manufacturer's guidelines to ensure optimal results and extend the coil's lifespan.

- Q: Can aluminum coils be used in food processing industries?

- Yes, aluminum coils can be used in food processing industries. Aluminum is non-toxic, lightweight, and has excellent conductivity, making it suitable for various applications in the food industry. It is commonly used in food packaging, cooking utensils, and equipment, including heat exchangers and refrigeration units. Additionally, aluminum coils are corrosion-resistant and easy to clean, making them a safe and hygienic choice for food processing.

- Q: how tall is a crushed aluminium soda can compared to a non crushed one.i need measurements in centimeters please.ALSO!! AN IMAGE that actually has both of the two with the measurements would be SUPER HELPFUL

- I don't understand why you can't just measure a can, then crush it and measure it again. And with the number of cellphones kids have today, every one can take a picture. Why do we need to do this for you?

- Q: What are the different surface treatments applied to aluminum coils?

- There are several different surface treatments that can be applied to aluminum coils to enhance their appearance, protect against corrosion, and improve their overall performance. Some of the most common surface treatments for aluminum coils include: 1. Anodizing: Anodizing is an electrochemical process that forms a protective oxide layer on the surface of the aluminum. This treatment enhances the corrosion resistance of the coils and provides a decorative finish. Anodized aluminum coils are available in a wide range of colors and finishes. 2. Painting: Painting is a surface treatment that involves applying a coating of paint to the aluminum coils. This treatment provides a decorative finish and can also enhance the corrosion resistance of the coils. Painted aluminum coils are commonly used in architectural applications where aesthetics are important. 3. Laminating: Laminating is a process that involves applying a thin layer of protective film to the surface of the aluminum coils. This treatment provides a protective barrier against scratches, abrasion, and UV radiation. Laminated aluminum coils are often used in applications where durability and weather resistance are important. 4. Polishing: Polishing is a mechanical process that involves buffing the surface of the aluminum coils to create a smooth and shiny finish. This treatment enhances the appearance of the coils and can also improve their corrosion resistance. Polished aluminum coils are commonly used in decorative applications where a high-end look is desired. 5. Brushing: Brushing is a mechanical process that involves creating a pattern of fine parallel lines on the surface of the aluminum coils. This treatment gives the coils a brushed or satin finish and can also help to hide imperfections and scratches. Brushed aluminum coils are often used in applications where a modern and sleek appearance is desired. Overall, the choice of surface treatment for aluminum coils depends on the specific application requirements and desired aesthetic. Each treatment offers unique benefits in terms of appearance, corrosion resistance, and durability, allowing manufacturers and designers to select the most suitable option for their needs.

- Q: What are the common sizes of aluminum coils used in roofing?

- The common sizes of aluminum coils used in roofing can vary depending on the specific needs and requirements of the project. However, some popular sizes include 24-inch, 36-inch, and 48-inch widths. These sizes are often chosen for their compatibility with standard roofing systems and their ability to cover a wide surface area efficiently. Additionally, the thickness of the aluminum coil can also vary, with common options ranging from 0.019 inches to 0.032 inches. Ultimately, the size of the aluminum coil used in roofing will depend on factors such as the size of the roof, the desired aesthetic, and the local building codes and regulations.

- Q: Are aluminum coils suitable for high-pressure applications?

- No, aluminum coils are not suitable for high-pressure applications.

Send your message to us

High Quality Coil Aluminum Stock - Aluminium Pre-Painted Coil/Sheet Serie 3

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords