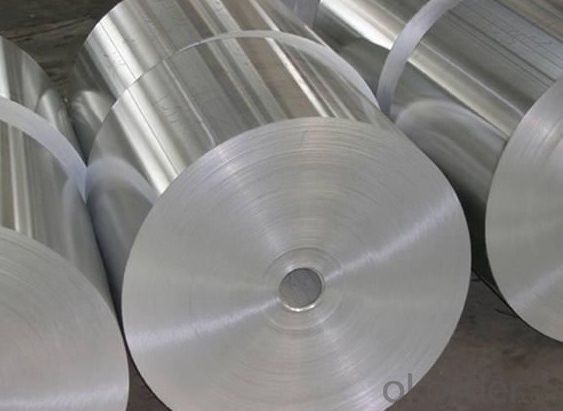

Wholesale Prepainted Aluminum Coil 3003 H16 H18 for Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

1.Alloy:1,3,5,8xxx

2.Thickness:0.2-12.0mm

3.Width:20-1900mm

4.Alloy:HO/H12/H14/H16/H18/H22/H24/H26/H112

DC or CC, A1050/A1100/A3105/A3003/3104/A5052/A5083/A8011 Aluminum coil for roofing, ceiling,gutter,decoration

Features:

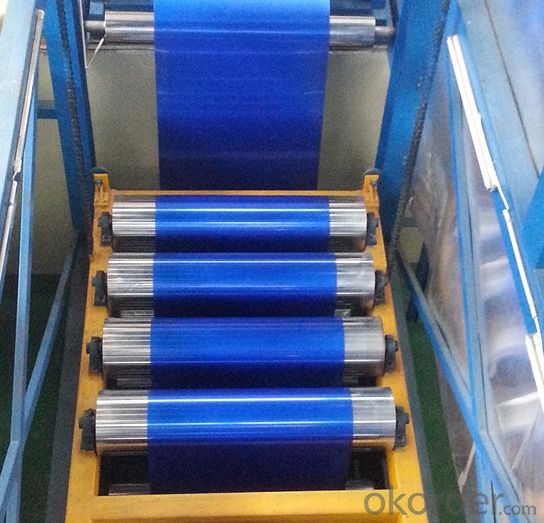

The surface can be plain ,colorful,stucco embossed,diamond embossed.aluminum coil for composite panel used to for building and indsutry, such as roofing sheets, ceilling, transporting,decoration,etc

aluminum coil for composite panel used to for building and indsutry, such as roofing sheets, ceilling, transporting,decoration,etc

The surface can be plain ,colorful,stucco embossed,diamond embossed.

Quality Certification:

According to EN and GB/T standards or as per agreed customer specifications.

Aluminum Coil for Beverage Cans, Food Cans and Closures Specifications

Alloy | Thickness(mm) | Width(mm) | Temper | DC or CC |

1050,1060,1070,1100,1235,1145 | 0.2-4.0 | 20-1500 | O,H12,H22,H14,H24,H16,H26,H18 | DC, CC |

4.0-12.0 | 1000-1900 | H111,H112 | DC | |

3003,3004,3105 | 0.2-4.0 | 20-1500 | O,H12,H22,H14,H24,H16,H26,H18 | DC, CC |

4.0-12.0 | 1000-1900 | H111,H112 | DC | |

5052,5083,5754,5005 | 0.2-4.0 | 20-1500 | O,H12,H22,H14,H24,H16,H26,H18 | DC |

4.0-12.0 | 1000-1900 | H111,H112 | DC | |

8011 | 0.0065-0.2 | 20-1200 | O,H22 | DC,CC |

FAQ of Color Coated Aluminum Coil 3003 H16 H18 for Composite Panel:

1.Superior quality of raw material.

2.Reasonable and stable chemical composition.

3.Accurate tolerance.

4.Goode mechanical property.

5.We have the certificate of ISO9001.

- Q: How to pull the aluminum coil purchased into aluminum sheet?

- You can use decoiler machine, but after decoiling, the embossment of embossed aluminum sheet will become very shallow.

- Q: This question asks about potential health hazards associated with the use of aluminum coils.

- <p>There are concerns regarding the use of aluminum coils, particularly in cooking and food preparation, due to the potential for aluminum to leach into food. While aluminum is generally recognized as safe, excessive intake over a long period has been linked to various health issues, including neurological disorders and cognitive impairment. However, the risk is considered low for most people, as the body does not absorb a significant amount of aluminum from food or cookware. It's important to note that the scientific community has not reached a consensus on the extent of these risks, and further research is needed. To minimize potential exposure, it's recommended to use alternative cookware materials like stainless steel or cast iron, especially for acidic foods that may increase aluminum leaching.</p>

- Q: This question is asking about the potential negative effects or hazards associated with the use of aluminum coils.

- <p>The use of aluminum coils can pose certain risks and dangers, primarily due to their high thermal conductivity and reactivity. When used in cooking or heating applications, aluminum coils can cause uneven heat distribution, which may lead to burning or melting of food. Additionally, aluminum can react with acidic or alkaline foods, potentially leaching aluminum into the food and causing health concerns such as neurological disorders and bone diseases. Moreover, aluminum coils can corrode over time, especially when exposed to moisture or certain chemicals, which can weaken their structure and pose a risk of breakage or injury. It's important to use aluminum coils appropriately and to monitor their condition regularly to minimize these risks.</p>

- Q: Can aluminum coils be used in high-vibration environments?

- Yes, aluminum coils can be used in high-vibration environments. Aluminum is known for its high strength-to-weight ratio, which allows it to withstand vibrations without significantly deforming or breaking. Additionally, aluminum has excellent corrosion resistance properties, making it suitable for various environmental conditions. It is commonly used in industries such as automotive, aerospace, and electronics, where high-vibration environments are prevalent. However, it is important to ensure that the aluminum coils are properly designed and installed to minimize any potential issues arising from vibration.

- Q: Can aluminum coils be recycled multiple times without losing their properties?

- Yes, aluminum coils can be recycled multiple times without losing their properties. Aluminum is a highly recyclable material, and the recycling process for aluminum coils involves melting the metal down to its liquid form and then reshaping it into new coils or other aluminum products. This process can be repeated over and over again without compromising the quality or properties of the aluminum. In fact, recycling aluminum requires only around 5% of the energy needed to produce new aluminum from raw materials, making it an environmentally friendly choice. Additionally, the properties of aluminum, such as its strength, durability, and resistance to corrosion, remain intact during the recycling process, ensuring that the recycled aluminum coils can be used for various applications just like the original ones. Therefore, recycling aluminum coils not only conserves valuable resources but also helps reduce waste and promote sustainability.

- Q: What's the difference between an aluminum alloy strip and an aluminum coil?

- The specifications are different. Generally speaking, the aluminum strips are of small size, and the aluminum rolls are of large size

- Q: How do aluminum coils contribute to the reduction of carbon footprint?

- Aluminum coils contribute to the reduction of carbon footprint in several ways. Firstly, aluminum is a lightweight material, which means that it requires less energy to transport compared to heavier materials like steel. This reduces fuel consumption and emissions associated with transportation, thereby reducing the overall carbon footprint. Additionally, aluminum is highly recyclable and can be recycled indefinitely without losing its quality. The process of recycling aluminum requires significantly less energy (up to 95% less) compared to producing new aluminum from raw materials. By using aluminum coils, which can be easily recycled, we can reduce the demand for new aluminum production, which in turn reduces the carbon emissions associated with the extraction and refining of raw materials. Moreover, aluminum coils have excellent thermal conductivity properties. This makes them highly efficient for use in heating and cooling systems, such as air conditioning units and heat exchangers. By using aluminum coils in these applications, energy consumption is reduced as they facilitate the transfer of heat more efficiently, resulting in lower energy consumption and reduced carbon emissions. Lastly, aluminum coils have a longer lifespan compared to other materials, such as copper or steel. This means that they require less frequent replacement, resulting in reduced waste generation and lower carbon emissions associated with the manufacturing and disposal of new coils. Overall, the utilization of aluminum coils contributes to the reduction of carbon footprint through its lightweight nature, recyclability, thermal conductivity properties, and longer lifespan. By choosing aluminum coils over other materials, we can make significant strides in reducing carbon emissions and promoting a more sustainable future.

- Q: Inquiry about the feasibility of using aluminum coils for crafting jewelry or accessories.

- <p>Yes, you can use aluminum coils to make jewelry or accessories. Aluminum is lightweight, durable, and non-allergenic, making it a popular choice for crafting. It's easy to shape and work with, and it's also cost-effective compared to precious metals. You can create rings, bracelets, necklaces, and various other decorative items. Just ensure you use the right tools and safety precautions when working with metal, and finish your creations with appropriate polishing and sealing to enhance their appearance and longevity.</p>

- Q: Are aluminum coils resistant to moisture?

- Yes, aluminum coils are resistant to moisture. Aluminum is inherently corrosion-resistant, which means it has a natural ability to resist the effects of moisture and other environmental factors. This makes it an excellent choice for applications where moisture resistance is crucial, such as in HVAC systems, refrigeration units, and outdoor equipment. Additionally, aluminum can be further protected with a variety of protective coatings and treatments to enhance its resistance to moisture and extend its lifespan. Overall, aluminum coils are known for their durability and ability to withstand moisture, making them a reliable choice in various industries.

- Q: I have a edelbrock aluminum intake that was sitting around for a year and it has some fading with a little corrosion. What's a good cleaner or chemical I can use to clean it up?

- I use Mother aluminum polish. It'll take a lot of patience and elbow grease but it works.

Send your message to us

Wholesale Prepainted Aluminum Coil 3003 H16 H18 for Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords