3003 H24 PE and PVDF Color Coated Aluminum Coil of Aluminum 6 Wide for Aluminum Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

3003 H24 PE and PVDF color coated aluminum coil for aluminum composite panel

We provide a series of aluminum products,such as aluminum circle,aluminum sheet,aluminum coil,mirror aluminum plate,embossed aluminum plate,aluminum plate,color aluminum plate,etc .

1) PE coated aluminum coil is made via rolling painting and baking, it has various bright colors with small color differences. It is resistant against impact and easy to be machined. All properties meet or surpass the national standard. the product is widely used in indoor and shop front decoration, ceiling roof tile, wall panel, advertisement board, counter, household electric apparatus, and inner and outer decoration of cars and ships.

2) The main raw material of PVDF fluorine carbon coating is PVDF fluorine carbon resin-polyvinylidene fluoride fiber. By maximum electric performance of fluorine atom, a stable and high fluorine bond can be formed. In addition to, the unique equal symmetrical molecular structure, the product are given with outstanding weathering resistance, excellent ultraviolet radiation resistance, and highly endurable corrosion resistance. The outdoor product color and brightness can be maintained for over 20 years. Because of high weather and impact resistance and the high pliability, the product has excellent machining property, and the coated colored panel can be further treated for pattern pressing. This product can be provided in two types: traditional fluorine carbon and nanometer fluorine carbon.

Raw Material

Aluminum Grade:1100,3003,5005.

Temper:H14,H16,H18,H24,etc.

Surface Coating: PE&PVDF

Specification

Thickness:0.024-0.7mm

Coil Width:56-2000mm

Coating Thickness:18-30um.

ID:405/505mm

Coil Weight:0.15-3MT

Gloss:10-90%(EN ISO-2813:1994)

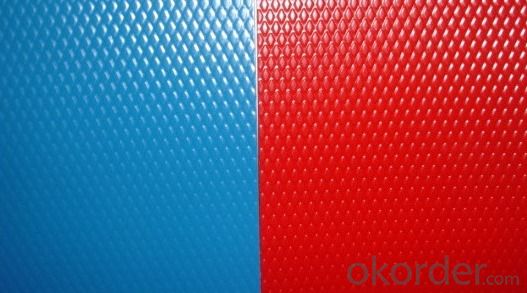

Color: solid, metallic, glossy, real stone, timber design, embossed, etc.

You can choose our color chart, or we adjust the special color as the samples you offer.

Product Feature

1) High gloss

2) High flexibility

3) Excellent impact resistance

4) Excellent weather-proof resistance

5) Anti-ultraviolet

6) High erosion resistance

7) Stable color and gloss

8)Good mechanical processing performance

Coating Characteristic Table

Pre-painted Aluminum Coil | |

Grade and Temper | Alloys: 1050, 1100, 3003,3005,3105, 5005,5052,6061,6063,8011,etc Temper: 0-H112 |

Widths | 35mm -1700 mm available |

Thickness | 0.25mm - 4.0mm |

Coating | PE, PVDF or Customize |

Coil Specifications | I.D.: 405mm, 505mm O.D.: 800mm – 1270mm |

Color | Customized |

Packing Detail | Wooden pallet either eye to wall or eye to sky |

Application | Aluminum Suspended Ceiling ,Aluminum Sandwich Panel, Wall Cladding Panel, Roller Shutter, Metal Roofing, Conner Bead, etc |

Coating Type

| Test Item | Coating | |||||||

| PVDF | PE | |||||||

| Double layers | Three layers | |||||||

| Coating Thickness | ≥24 | ≥30 | ≥18 | |||||

| Glossy Tolerance | While 60°gloosy value ≥80 unit,tolerance±10 unit | |||||||

| While 60°gloosy value ≥20-80 unit,tolerance±7 unit | ||||||||

| While 60°gloosy value<20 unit,tolerance±5 unit | ||||||||

| Pencil Hardness | ≥1H | ≥2H | ||||||

| Flexibility of coating | While ≤2T,coating no crack or peer off | |||||||

| Adhesive property | 0 or 1 grade | |||||||

| Impact resistance | coating no crack no peer off | |||||||

| Acid resistance | Surface immersed with 5% HCL(V/V) for 48H | Surface immersed with 2% HCL(V/V) | ||||||

| without change | for 24H without change | |||||||

| Solvent Resistance | Brushing 200 times with butanone no appearance | Brushing 100 times with butanone no | ||||||

| to bottom | appearance to bottom | |||||||

| Chromatism | The coating color is almost the same as confirmed by buyer and seller,the color difference tested by | |||||||

| colorimeter between single coating and sample is less than 1.2(ΔE≤1.2),same lot products color difference | ||||||||

| ΔE≤1.0 | ||||||||

| Salt Fog Resistance | Outside 2mm the line which is scratched,no corrosion | |||||||

| and coating peel off | ||||||||

| Moisture Resistance | Coating change is less than 1 grade after 1000 hours | |||||||

| humidity test | ||||||||

| Weather Resistance | After 2000 hours xenon lamp shining test(artificially | |||||||

| accelerating ageing test),no powder come into being, | ||||||||

| glossy retention rate(after and before test percent rate) | ||||||||

| ≥85%,color change degree at least reaching to 1 grade | ||||||||

| Note:The test is as per China National Standard and Nonferrous Metals Industry Standard for color coated aluminum | ||||||||

| coil and ACP | ||||||||

FAQ of Coated Aluminum Coil for Aluminum Composite Panel

1.Superior quality of raw material.

2.Reasonable and stable chemical composition.

3.Accurate tolerance.

4.Goode mechanical property.

5.We have the certificate of ISO9001.

- Q: Are aluminum coils suitable for architectural applications?

- Yes, aluminum coils are commonly used in architectural applications due to their durability, lightweight nature, corrosion resistance, and versatility in design options. They are often used in roofing, siding, facades, and other architectural elements, offering a long-lasting and aesthetically pleasing solution.

- Q: What are the different grades of aluminum used in coil production?

- The different grades of aluminum used in coil production typically include 1100, 3003, and 5052. These grades vary in terms of their composition and properties, allowing for specific applications and requirements in various industries.

- Q: Can aluminum coils be used for food storage containers?

- Indeed, food storage containers can be made from aluminum coils. Aluminum is widely chosen as a material for such containers because of its numerous advantageous qualities. Notably, it is lightweight, sturdy, and possesses exceptional thermal conductivity, enabling it to distribute heat evenly for effective cooking or cooling purposes. Moreover, aluminum is non-toxic, devoid of odor, and resistant to corrosion, rendering it a secure option for food storage. Additionally, it acts as a proficient shield against light, moisture, and oxygen, thereby assisting in maintaining the freshness and quality of the stored food. All in all, opting for aluminum coils for food storage containers can be a dependable and practical decision.

- Q: Are there any limitations on the width-to-thickness ratio of aluminum coils?

- Yes, there are limitations on the width-to-thickness ratio of aluminum coils. The width-to-thickness ratio is an important factor in determining the overall strength and performance of aluminum coils. If the ratio is too high, it can lead to issues such as buckling, warping, or even failure of the coil. The specific limitations on the width-to-thickness ratio depend on various factors such as the alloy composition, temper, and intended application of the aluminum coil. Different alloys and tempers have different mechanical properties and can handle different ratios. Additionally, the intended application of the coil, such as roofing, automotive, or packaging, may have specific requirements for the width-to-thickness ratio. Manufacturers typically provide guidelines and specifications for the acceptable width-to-thickness ratio based on their product offerings. These guidelines ensure that the coils are used within their intended capabilities and prevent any issues related to excessive width-to-thickness ratios. It is important for users and designers to consider these limitations and guidelines when selecting and utilizing aluminum coils. Failure to adhere to these limitations can result in compromised performance, increased risk of damage, and potential safety concerns. Therefore, it is crucial to consult the manufacturer's recommendations and industry standards to determine the appropriate width-to-thickness ratio for a given application.

- Q: Are aluminum coils suitable for electrical conductors?

- Yes, aluminum coils are suitable for electrical conductors. Aluminum is a widely used material in the electrical industry due to its excellent electrical conductivity. It has around 61% conductivity of copper, which is the most commonly used metal for electrical conductors. Aluminum coils are lightweight, cost-effective, and have good thermal conductivity, making them a popular choice for various electrical applications. However, it is important to note that aluminum has a lower tensile strength compared to copper, so it may require a larger cross-sectional area to achieve the same level of current carrying capacity. Additionally, proper insulation and connectors are necessary to prevent oxidation and ensure efficient electrical conductivity in aluminum coils.

- Q: Almost every restaraunt uses aluminium foils and polyehylene for packing foods - that you carry to home.How safe is this ?For how long would the temperature be mainitained ?and within what time if consumed and is it safe ?

- Aluminium (Al) foil is bad for packaging because some of the Al will be absorbed by the food and too much Al is toxic. Instead of Al cooking vessels you should use stainless steel vessels because some Al will end up in your food from the Al containers or vessels. If you conduct a search for Aluminium (OR Al) poisoning you should learn more. A search for aluminium (OR Al) + toxic dose (OR amount) may also be useful.

- Q: Can aluminum coils be used for outdoor applications?

- Yes, aluminum coils can be used for outdoor applications. Aluminum is a highly versatile and durable material that can withstand various weather conditions and temperatures. It is resistant to corrosion, making it suitable for outdoor environments where moisture and humidity are present. Additionally, aluminum coils are lightweight, which makes them easier to transport and install in outdoor settings. They are commonly used in outdoor applications such as roofing, siding, gutters, and HVAC systems. Overall, aluminum coils are a reliable choice for outdoor applications due to their strength, corrosion resistance, and longevity.

- Q: Why does aluminum foil barely get hot in the oven, but catch fire in the microwave?

- It has to do with the resonance of the microwave radiation with the 'points' on the aluminium foil. We don't think of foil as having 'points'...to us it looks smooth. However, when the microwave bouce around in the oven, they find each and every uneven surface on the foil. In layman's terms, the microwaves 'collide', causing a build-up of charge and energy. You'll notice that many pre-packaged microwave meals contain a 'crisping' area on the cardboard that resembles aluminium. This is a specially treated foil that won't set up a resonance, but instead will concentrate the microwaves in a particular area, causing the food to cook much faster in a small, external area. The result: a nice, crispy shell on your otherwise limp and tasteless Hot Pocket! Enjoy!

- Q: Can aluminum coils be used for sound insulation?

- Indeed, sound insulation can be achieved by employing aluminum coils. By virtue of its high density and capacity to absorb and disperse sound waves, aluminum possesses exceptional qualities for soundproofing purposes. When utilized in the form of coils, aluminum effectively obstructs and reflects sound, thereby diminishing noise transmission and furnishing insulation. Moreover, aluminum coils boast effortless installation and exhibit resistance against corrosion, rendering them a robust and enduring choice for soundproofing applications.

- Q: I am writing a science-fiction story, and I am planning on making Aluminum this ultra-valuable element (Which adds irony - Aluminum is the third most abundant element on Earth!) Even if ol' atomic no. 13 is as common throughout the universe as it is on Earth, I can bring up 'multiverse' to get away with it. I think it'd still be nice to know.

- Interesting, the aluminum must flow? Aluminum is not as common as other elements. It is not readily produced in the cores of stars through the alpha-capture process (which produces things like carbon, oxygen, neon, magnesium, silicon, etc.). This means it is only produced via supernova explosions. The table in Wikipedia (see link below) will give you an idea of the relative abundance to other elements. (Notice that magnesium and silicon, which are before and after aluminum, are nearly 100 times more abundant). As a fellow, Sci-Fi enthusiast, I'd remind you to make you're story believable. If you decide that your universe won't have supernovae, remember that would mean there would be no iron, gold, uranium, etc. My answer has been long enough, but I'm sure you have an idea why aluminum is so abundant on the Earth's crust so I'll stop here.

Send your message to us

3003 H24 PE and PVDF Color Coated Aluminum Coil of Aluminum 6 Wide for Aluminum Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords