Aluminum Gutter Profiles - Alu Perfil de Aluminio

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetal with appearance ranging from silvery to dull gray,depending on the surface roughness. It is nonmagnetic and does not easilyignite. A fresh film of aluminium serves as a good reflector (approximately92%) of visible light and an excellent reflector (as much as98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffnessof steel. It iseasily machined,cast, drawn and extruded.

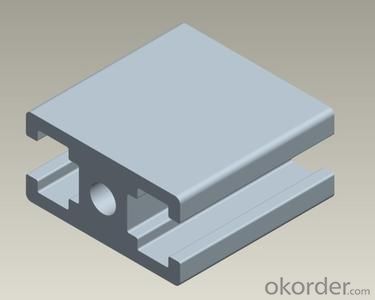

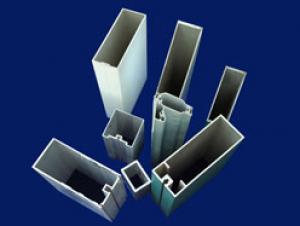

Alu Profile:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C at sight

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Guangzhou/Shenzhen port

4. Delivery time?

15-20 days after client’s deposit

- Q: This question asks for a method to determine the quantity of aluminum profiles required for a specific project.

- <p>To calculate the amount of aluminum profiles needed for a project, first, determine the dimensions and design of the structure. Measure the length, width, and height of the required profiles. Consider the number of profiles needed for each section of the project. Multiply the length of each profile by the number of profiles required. Sum these totals for all sections to get the overall amount of aluminum needed. Factor in a margin for cutting and waste to ensure you have enough material. Consult with suppliers or use specialized software for more precise calculations, especially for complex projects.</p>

- Q: This question asks if aluminum profiles can be recycled through existing recycling programs or facilities in the user's local area.

- <p>Yes, aluminum profiles can typically be recycled using existing recycling programs or facilities. Most recycling centers accept aluminum, and aluminum profiles are no exception. However, it's always a good idea to check with your local recycling program to confirm their specific guidelines and requirements. Some facilities may require aluminum profiles to be clean and free of any non-aluminum parts before recycling. You can also look for local scrapyards or metal recycling businesses that specialize in aluminum and may offer better rates for your aluminum profiles.</p>

- Q: What are the different colors available for aluminum profiles?

- There are several different colors available for aluminum profiles, allowing for endless possibilities in design and aesthetics. Some of the most common colors include silver, black, bronze, and white. These colors are achieved through various finishing techniques such as anodizing and powder coating. Anodizing involves creating a protective oxide layer on the surface of the aluminum, which can be dyed to achieve different colors. Powder coating, on the other hand, involves applying a dry powder paint to the aluminum and then curing it under heat, resulting in a durable and vibrant finish. Additionally, custom colors can also be created through the use of specialized coatings and finishes. Overall, the availability of different colors for aluminum profiles allows for versatility in architectural, industrial, and decorative applications.

- Q: How do aluminum profiles perform in terms of thermal conductivity?

- Aluminum profiles are known for their excellent thermal conductivity. Thermal conductivity refers to the ability of a material to transfer heat. Aluminum has a high thermal conductivity value, which means it can efficiently transfer heat from one point to another. This property makes aluminum profiles highly suitable for applications that require heat dissipation or heat transfer, such as in the construction of heat sinks, radiators, or electrical components. Additionally, the high thermal conductivity of aluminum profiles allows for faster and more efficient cooling, making them ideal for applications that involve thermal management.

- Q: Can aluminum profiles be used for swimming pool covers?

- Yes, aluminum profiles can be used for swimming pool covers. Aluminum is a durable and lightweight material that is resistant to corrosion, making it suitable for outdoor applications like swimming pool covers. Additionally, aluminum profiles can be easily customized to fit the specific dimensions and design requirements of the pool cover.

- Q: Changhe brand aluminum can?

- Profile is not bad, but visibility is not too large, the whole is still very good, cost-effective

- Q: Can aluminum profiles be used in HVAC systems?

- HVAC systems can utilize aluminum profiles, which are lightweight and durable materials commonly found in various industries. Aluminum profiles offer numerous advantages, including excellent thermal conductivity, resistance to corrosion, and easy malleability. In HVAC systems, aluminum profiles are frequently employed for various components such as ductwork, air vents, and heat exchangers. The ductwork made from aluminum profiles is lightweight, easy to install, and resistant to corrosion. Consequently, it has become a popular choice for HVAC installations. Aluminum air vents facilitate efficient airflow and can be effortlessly adjusted to control the direction and volume of air. Furthermore, aluminum heat exchangers are extensively used in HVAC systems. The exceptional thermal conductivity of aluminum allows for efficient heat transfer, making it an ideal material for applications that necessitate heat exchange. Additionally, the corrosion resistance of aluminum ensures the longevity and dependability of heat exchangers, even in harsh environments. In conclusion, due to their lightweight nature, durability, thermal conductivity, and corrosion resistance, aluminum profiles are an appropriate choice for HVAC systems. They enhance the overall efficiency and performance of HVAC systems while guaranteeing long-lasting functionality.

- Q: This question asks for methods to protect aluminum profiles from damage during the processes of transportation and storage.

- <p>To prevent damage to aluminum profiles during transportation and storage, follow these practices: Use protective packaging such as bubble wrap or foam padding to cushion the profiles. Ensure that profiles are stacked evenly and securely to avoid pressure points. Store profiles in a dry, cool place away from direct sunlight and moisture to prevent warping or corrosion. Secure the cargo during transportation to prevent shifting, and handle with care to avoid dropping or mishandling. Regularly inspect storage areas for potential hazards like pests or leaks that could cause damage.</p>

- Q: What is the nitriding process of aluminum extrusion die?

- The principle of nitridation:Gas nitrocarburizing, that is gas nitrocarburizing, refers to low temperature nitrocarburizing based on gas nitriding and carburizing. Commonly used media have 50% ammonia, +50% endothermic gas (Nitemper method); 35%-50% ammonia, +50-60% exothermic gas (Nitroc method) and ammonia through the drip ethanol or formamide and so on. In soft nitriding, because of the high solubility of carbon atoms in the epsilon phase, the soft nitrided surface is a common compound of carbon and nitrogen, which is good in toughness and wear resistant.In the process of gas nitrocarburizing, due to the extremely low solubility of carbon atoms, it quickly reaches saturation state and precipitates many super micro cementite points. These cementite particles, as the core of the crystallization of nitrides, contribute to the formation of nitrides. When the surface nitrogen concentration reaches a certain level, the epsilon phase is formed, while the carbon solubility of the epsilon phase is very high, which in turn accelerates the dissolution of carbon.After gas nitrocarburizing, its structure is composed of epsilon phase, gamma phase and nitrogen containing cementite Fe3 (C, N), carbon will reduce the diffusion rate of nitrogen, so the thermal stress and the stress of the tissue are hard, the nitriding is large and the layer is thinner. But at the same time, because the soft nitride layer does not exist. Therefore, the nitride layer, better toughness than hard nitriding

- Q: Can aluminum profiles be used for creating display systems?

- Yes, aluminum profiles can be used for creating display systems. Aluminum profiles are lightweight, durable, and easy to work with, making them ideal for constructing various types of displays such as exhibition stands, trade show booths, and retail displays. They can be easily customized and allow for modular designs, enabling flexibility in creating unique and eye-catching display systems. Additionally, aluminum profiles offer a sleek and professional appearance, making them a popular choice in the display industry.

Send your message to us

Aluminum Gutter Profiles - Alu Perfil de Aluminio

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords