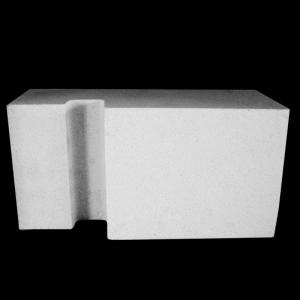

Acid Resistance Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

CMAX acid resistance brick is specially used as lining in reaction tower of chemical plants, fertilizer factories and sulfuric acid industries or inside the corrosion-resistance pool and ditch.

Feature

Strong acid and alkali resistance

Size available as customer’s requirement

Application

It is widely used in corrosion-resisting liner of petroleum, chemical industry, chemical fertilizer, food, chemical fiber, laboratory, pharmacy, papermaking, generate electricity, smelt, electroplating room, and the inner corrosion-resisting lining of tower, pool, pot, tank, etc. It is also used for sewage conduit and open-air floor.

- Q:Cleaning metal surface rust stain, is it better to weld sulphuric acid or nitric acid?

- Acid etching is a chemical cleaning process to remove metal oxide and other impurities from the acid aqueous solution. As the acid and corrosion are more economical and suitable for continuous operation, it is the most effective way to remove the oxide surface of metal surface of large tonnage products. Especially cleaning iron and steel products, such as billets, ingots, steel plates, steel strips, wires, pipes and so on. Can also be used for steel forgings, casting cleaning, rust removal

- Q:What brand does acidproof ceramic tile ten big famous brands have?

- Now let's introduce in detail of acid resistant ceramic ten brand-name what brand, in fact the ten major brands of ceramic tile manufacturers have to choose acidproof tile, tile acid, these ten brands of ceramic tile manufacturers to be sure, but the ten tile brand ranking of two, you can go to compare, look at the two ten famous brand rankings have what different tiles.

- Q:The difference between acid and heat resistant lightweight castables and acid resisting bricks

- The difference between acid and heat resistant lightweight castables and acid resisting bricks:Acid resistant brick is a ceramic product, which is fired by high temperature. The casting material is poured by chemical reaction after the material is diluted.

- Q:How to clean the acid brick surface dirt?

- Daily cleaning of bricks can be done with detergent, soap and other cleaning.

- Q:Does the chimney have high acid resistance?

- The chimney particles and gases, mostly coal tar products, material acidic, therefore, take good acid resistance, acid proof brick, Grouts also used potassium silicate clay acid is preferred. If it is an ordinary high alumina brick, it does not meet the requirements of acid resistance, and only the chimney lined with acid resistant bricks.

- Q:Consult: water treatment room anticorrosive usable granite and acid resisting brick, these two kinds of material what?

- RZG garnet is almost insoluble in acid insoluble in alkali, common for the diamond 12 face angle of 38 or four surface features can ensure that different crystal polyhedron particles than other material between ordinary circular or elliptical particles can produce voids more suitable, can play a better effect of filtration and antisepsis.

- Q:Construction method of acid proof brick

- Construction preparationFamiliar with drawings, specifications, technical disclosure, do a good job of the handover process.Material preparation: the anti-corrosion materials used in this project are stored in the appropriate warehouse (site), and the incoming materials are tested to comply with the requirements of the HGJ229-91 specification.Equipment preparation: cutting machine, mixer, grinder, trolley, cement plate, rope, hose, shovel, wipe, steel scraper, rubber hammer, steel wire brush, brush, putty knife, the level of scale, by foot, rope, wire, small pendant, Jue measuring cup, scales, tarps, ventilation and lighting equipment.

- Q:98% acid tank cofferdam can use acid resistant brick?

- The hydrogenation unit has a large amount of light hydrocarbons in its memory, and if it leaks, it will cause serious accidents. Therefore, we should pay enough attention to the operation of the light hydrocarbon pump.

- Q:The acid resistance is 99.4%. Is this acid resistant brick very bad?

- Bending strength, 39.2., water absorption, 0.5-2.0., quench, hot, 100du, cycle without cracks, peeling, etc. the quality of acid resistant tiles is mainly reflected in water absorption, the lower the water absorption, the higher the acid resistance

- Q:How much is one square meter of acidproof tile?

- Acid proof brick is made of quartz, feldspar, clay as the main raw material, acid resistant materials by high temperature firing, with acid of high, low water absorption, is not easy to be oxidized at room temperature, is not easy to be medium pollution characteristics.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Acid Resistance Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords