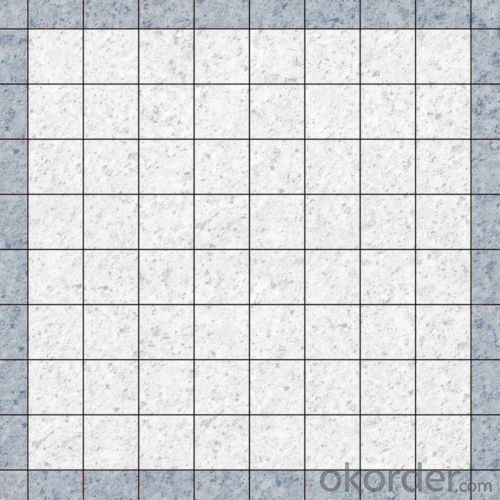

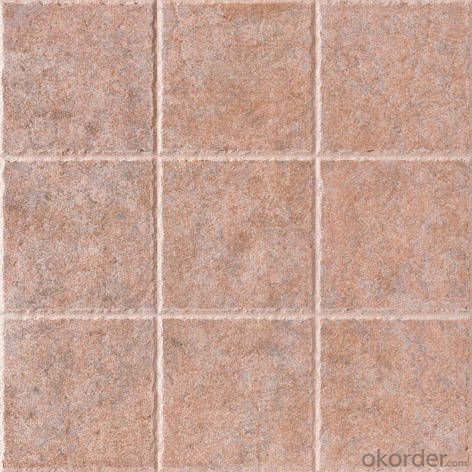

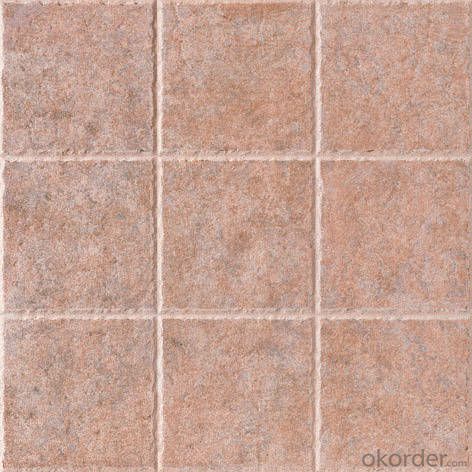

Acid Resistant Sintered Paving Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

1.Acid-resistant for paving brick2.Excellent quality

3.Excelletn abrasion resistance

4.High water-permeable quality

Specification and size

material: pottery clay or clay

color: red,brown,chestnut,khaka,and so on

size is availabe arrording to customer's requirements.

Feature

1.excellent quality and abrasion resistance

2.acid-resistance.

3.using long life

4.easy to maintain

5.non-polluting

pysical and chemical index

| Item | requirement |

| ≤positive skin and strick the maximum projection size of defect | 10.0mm |

| ≤edge off missing the maximum angle of projection size | 15.0mm |

| ≤non-through crack length size of the largest projection | 10.0mm |

| through the cracks | not allowed |

| stratified | not allowed |

brick size tolerance of physical and chemical

Item | requirements |

length,width | ±2.0 |

thickness | ±2.0 |

thickness difference | ±2.0 |

vertical | ≤2.0 |

flatness | ≤2.0 |

straight angle | ≤2.0 |

- Q: How to clean the acid brick surface dirt?

- Daily cleaning of bricks can be done with detergent, soap and other cleaning.

- Q: Acid proof brick, acid resistant porcelain in the paste process with no seam

- Acid resistant brick, acid resistant ceramic tile in the shop, many users only pay attention to beauty, and use not leave seam shop, or shop too tight, too close, easy to leave hidden dangers for the future.

- Q: What is anticorrosive floor tile?

- The above construction method is simple, and the normal paving tiles are the same. It is convenient to add 2-3mm cross micelles when leaving gaps.

- Q: How can acid proof cement be used?

- When in use should be mixed after the finished product into the container, after adding water glass solution, mixing uniformly rapidly; usually with less than one hundred kilograms of stir, each tune into the product to be used within 50 minutes.

- Q: The difference between acid and heat resistant lightweight castables and acid resisting bricks

- Acid proof brick is the use of water glass as pointing agent according to the conventional construction methods of building materials, paving the way to take, masonry construction and pouring material molding, a molding, want to make what kind of direct like making the plastic bottle mold as a complete irrigation mode.

- Q: Is it necessary to use sulphate resisting cement in alkaline areas?

- 1. acid can be applied in chemical industry, petroleum, metallurgy, machinery, textile, papermaking, sugar and other industrial equipment in construction engineering, the floor in the equipment foundation, acid corrosion and acid storage tank, chimney lining workshop, building waste and gaseous acid corrosion, can be prepared by acid resistant clay masonry brick acid and board; can be mixed with acid and coarse aggregate (gravel), fine aggregate (sand) acid and preparation of acid resistant concrete.2. can not be used by hydrofluoric acid, fluosilicate, 300 degrees above phosphoric acid and advanced fatty acids and oleic acid, palmitic acid, and alkaline salt erosion engineering. When used in the food industry, sodium fluoride in sodium fluosilicate should be tested to prove that it is not harmful to humans.

- Q: Which acid proof tile factory is reliable in quality?

- We all know that the main component of acid resistant ceramic which is silica, liangdun acid resistant ceramic material is used by Shanxi local quartz stone, containing a large number of silicon content, acid resistant tiles can thus produced corrosion.

- Q: 98% acid tank cofferdam can use acid resistant brick?

- The operation temperature of some hot oil pumps in hydrogenation unit is higher, which is higher than the spontaneous ignition point of oil products. If there is leakage, it is prone to fire accidents. Therefore, the operation should pay attention to the operation of hot oil pump, pay attention to pump body, sealing and so on whether there is leakage, if leakage should be dealt with immediately.

- Q: The difference between polished tiles and glazed tiles?

- Just because of the surface layer, so the pattern will slowly fade, it looks very old, but the brick does not have this problem, the brick on the market, some does not completely block brick has a pattern, just by the superposition technique, will have almost half the above pattern.

- Q: Cleaning metal surface rust stain, is it better to weld sulphuric acid or nitric acid?

- Abrasive blasting is the physical cleaning of dry or suspended abrasive particles in the liquid to the surface of metal parts or products to remove corrosion products. Sand blasting can remove rust, oxide, dry dirt, molding sand or paint on metal surface.Abrasives used for dry blasting include metal sand, iron pellets, fine sand, glass, etc.. Factors such as hardness, density, particle size and shape shall be taken into account when selecting specific abrasives.Sandblasting equipment used by: no use of air sand thrown blade or impeller, pressure nozzle set rubidium: suction nozzle device, see second articles. Sand blasting cleaning is a common method of removing the corrosion products such as ferrous oxide and non-ferrous metal surface oxide

Send your message to us

Acid Resistant Sintered Paving Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords