AC Driver China Best Selling VFD Variable Frequency Drive 3 phase 380V

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.220V Single Phase Variable Frequency Drive 2.2KW

2.Advanced control technology

3.Easy to operate

220V Single Phase Variable Frequency Drive 2.2KW

General

CNBM frequency inverter is a high-quality, multi-function,

low-noise variable frequency drive which is designed, developed and manufactured according to international standards.

It can meet different needs of industrial conditions.

The inverter applies advanced control technology of space voltage vector PWM, with functions of constant voltage control, power-off restart, dead zone compensation, automatic torque compensation, online modification parameter, high-speed impulse input, simple PLC and traverse.

Product Name:CMAX-VCG15/P18.5T3 ~ CMAX-VCG18.5/P22T3

Application

Textile: coarse spinner, spinning frame, wrap-knitting machine, loom, knitting machine, silk-spinning machine, etc.

Plastic: extruder, hauling machine, decorating machine, etc.

Pharmacy: mixer, roaster, etc.

Woodworking: engraving machine, sander, veneer peeling lathe, etc.

Papermaking: single type papermaking machine, etc.

Machine tool: non-core grinding machine, optical lens grinding machine, cutting mill, etc.

Printing: cloth-washing machine, dye vat, etc.

Cement: feeder, air blower, rotary furnace, mixer, crusher, etc

Fan and pump: kinds of fans, blowers and pumps

Specification

Item | Specification | |

Input | Input voltage | 220/380V±15% |

Input frequency | 47~63Hz | |

Output | Output voltage | 0~input voltage |

Output frequency | 0~600Hz | |

Peripheral interface characteristics | Programmable digital input | 4 switch input, 1 high-speed impulse input |

Programmable analog input | AI1: 0~10V input AI2: 0~10V input or 0~20mA input, | |

Programmable open collector output | 2 Output (3.7kW and above: 1 Open collector output) | |

Relay Output | 1 Output (3.7kW and above: 2 Relay output) | |

Analog output | 2 Output, one is 0~10V, another is 0~20mA or 0~10V | |

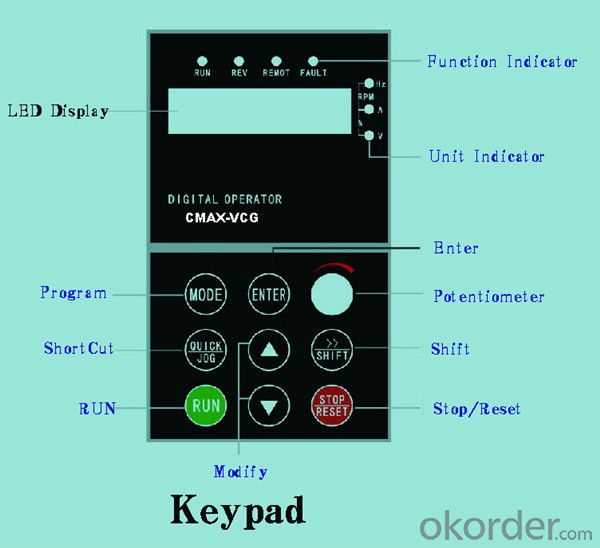

Keypad | Display:5-digit 8-section LED (Red), 2 indicators; parameter setting: 8 keys (including multi-function hot key ), 1 potentiometer | |

Technical performance characteristics | Control mode | All digital space voltage vector SVPWM algorism |

Overload capacity | G purpose: 150% rated current 60s P purpose: 120% rated current 60s | |

Speed ratio | 1: 100 | |

Carrier frequency | 1.0~10.0kHz | |

Torque compensation | Linear, multi-point, 1.3th power, 1.7th power, 2.0th power reduced torque; Compensation voltage range: automatic compensation and manual compensation 0.1~10% | |

Automatic voltage adjustment | It can automatically maintain output voltage constant when grid voltage fluctuates. | |

Automatic current adjustment | When the current is over current limit, under clocking automatically limits output current. | |

Function characteristics | Frequency setting mode | Keypad digital analog input, keypad potentiometer, impulse frequency, communication, multi-step speed and simple PLC, PID setting and so on, switch-over of setting modes. |

Simple PLC, multi-step speed control | 16-step speed control | |

Special function | Traverse control, length control, time control | |

QUICK/JOG key | User-defined multi-function hot key | |

Protection function | Over-current, Over voltage, under-voltage, over-heat, phase failure, over-load and motor over-load | |

Working condition | Installation site | Indoor, altitude of less than 1km, dust free, non-corrosive gases, no direct sunlight |

Application environment | -10°C~+40°C, 20~90%RH (no dew) | |

Vibration | Less than 0.5g | |

Storage temperature | -25°C~+65°C | |

Installation type | Wall-mounted type, floor cabinet type | |

Cooling mode | Air-forced cooling | |

- Q:What is the working principle of elevator frequency converter?

- The basic principle of VVVF elevatorAccording to the theory of motor, the speed formula of AC motor is:N=60f (1-s) /pUpper type: F is the stator frequency, and P is the pole count;S is slip; n is speed.

- Q:What's the difference between universal inverter and fan pump converter?

- Fan and pump load:In a variety of fans, pumps, oil pumps, with the rotation of the impeller, the air or liquid within a certain speed range of resistance is roughly proportional to the speed of the 2 side of the n. As the speed decreases, the torque decreases by 2 times the speed. The power required for this kind of load is proportional to the 3 power of the velocity. When the required air volume and flow rate are reduced, the frequency and speed of air flow can be regulated by the frequency converter, so the energy can be saved substantially. Because the power required at high speed increases with the speed, and is proportional to the speed of the three side, so the fan and pump load should not be used in the ultra power frequency operation

- Q:How does the frequency converter fit the brake unit and the brake resistor?!

- To calculate how much energy consumption, can be converted into electric current, to select the brake unit. You can also choose the braking resistance (to consider resistance temperature characteristics to choose), then select the brake unit with matching (see manufacturer manual).

- Q:What is the frequency converter AVR?

- When the input voltage deviation from the rated value, the function can keep the output voltage constant, so under normal circumstances should be AVR action, especially when the input voltage is higher than the rated value, to protect the motor from excessive voltage caused by long-term insulation damage or high magnetic density caused by excessive heating core.

- Q:Does the number of inverter settings differ from the number of motor poles, and does it affect the use?

- Simple applications are unaffected. But if the high-end applications, such as elevators, cranes and other frequency converter using self-learning mode, the control performance will be affected. Common applications only affect the display speed of the inverter, and have no influence on the control equipment.

- Q:Electronic governor for single-phase motor speed control, frequency converter for three-phase motor speed regulation, what are their differences in speed control effect? How does the frequency converter adjust speed? Can you give me an example?

- The electronic governor for single-phase motor, by changing the access winding resistance and capacitance to adjust the motor speed, the speed of the output power supply for power has not changed, so the speed is not a kind of energy-saving control methods, such as the electric fan like for home.

- Q:What is the over-current of the inverter?

- External cause:?1, the motor load mutation caused by excessive impact, resulting in excessive flow.?2, the motor and motor cable phase or insulation damage to each other, resulting in short circuit turns to the ground, resulting in over-current.?3, over-current fault and motor leakage reactance, motor cable coupling reactance, so choose motor cable must be selected according to requirements.?4. Power factor correction capacitor or surge absorption device on the output side of inverter.?5. When the speed feedback signal is lost or abnormal, it will cause excessive flow, and check the encoder and its cable.

- Q:What's the role of an electric car, the part of a traditional car?

- Safe and reliable power on time sequence control.Motor controller, power, according to certain timing control, otherwise it will cause damage to the controller. When the driver presses the motor controller switch button, motor controller is connected to the vehicle controller switching command closed after the precharge contactor, the battery group through the precharge resistor to capacitor charging slow motor controller, when the motor controller detects the DC bus voltage reaches the rated input voltage of 90%, closed motor controller contactor, and cut off the precharge contactor at this time, the main electric motor controller completely to battery group, completed the main electrical power on the process.

- Q:The difference between soft starter and converter

- The soft starter is during the start-up of the equipment to take blood pressure or other ways to reduce the starting current of the inverter machine, the device is in operation according to the equipment load by changing the size of the power frequency and regulating equipment output.

- Q:What is the TTK converter produced?

- Characteristic:Compact structure design, flexible installation, advanced control algorithm: space voltage vector control technology, power failure restart, automatic voltage adjustment, dead time compensation, energy saving operation,The main and auxiliary setting, built-in PID, simple PLC, oscillating frequency and zero frequency difference, length control, precision control requirements; design and test in accordance with international standards, to ensure the reliability of the product; choose rich accessories.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AC Driver China Best Selling VFD Variable Frequency Drive 3 phase 380V

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords