China Best Selling VFD Variable Frequency Drive Three Phase 380V

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.220V Single Phase Variable Frequency Drive 2.2KW

2.Advanced control technology

3.Easy to operate

220V Single Phase Variable Frequency Drive 2.2KW

General

CNBM frequency inverter is a high-quality, multi-function,

low-noise variable frequency drive which is designed, developed and manufactured according to international standards.

It can meet different needs of industrial conditions.

The inverter applies advanced control technology of space voltage vector PWM, with functions of constant voltage control, power-off restart, dead zone compensation, automatic torque compensation, online modification parameter, high-speed impulse input, simple PLC and traverse.

Product Name:CMAX-VCG15/P18.5T3 ~ CMAX-VCG18.5/P22T3

Application

Textile: coarse spinner, spinning frame, wrap-knitting machine, loom, knitting machine, silk-spinning machine, etc.

Plastic: extruder, hauling machine, decorating machine, etc.

Pharmacy: mixer, roaster, etc.

Woodworking: engraving machine, sander, veneer peeling lathe, etc.

Papermaking: single type papermaking machine, etc.

Machine tool: non-core grinding machine, optical lens grinding machine, cutting mill, etc.

Printing: cloth-washing machine, dye vat, etc.

Cement: feeder, air blower, rotary furnace, mixer, crusher, etc

Fan and pump: kinds of fans, blowers and pumps

Specification

Item | Specification | |

Input | Input voltage | 220/380V±15% |

Input frequency | 47~63Hz | |

Output | Output voltage | 0~input voltage |

Output frequency | 0~600Hz | |

Peripheral interface characteristics | Programmable digital input | 4 switch input, 1 high-speed impulse input |

Programmable analog input | AI1: 0~10V input AI2: 0~10V input or 0~20mA input, | |

Programmable open collector output | 2 Output (3.7kW and above: 1 Open collector output) | |

Relay Output | 1 Output (3.7kW and above: 2 Relay output) | |

Analog output | 2 Output, one is 0~10V, another is 0~20mA or 0~10V | |

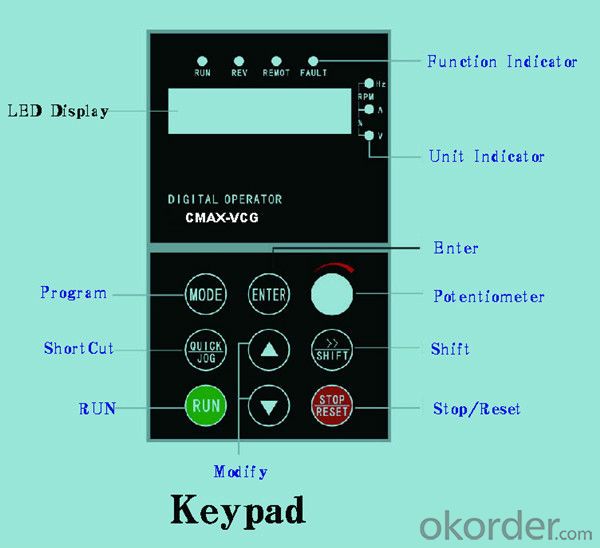

Keypad | Display:5-digit 8-section LED (Red), 2 indicators; parameter setting: 8 keys (including multi-function hot key ), 1 potentiometer | |

Technical performance characteristics | Control mode | All digital space voltage vector SVPWM algorism |

Overload capacity | G purpose: 150% rated current 60s P purpose: 120% rated current 60s | |

Speed ratio | 1: 100 | |

Carrier frequency | 1.0~10.0kHz | |

Torque compensation | Linear, multi-point, 1.3th power, 1.7th power, 2.0th power reduced torque; Compensation voltage range: automatic compensation and manual compensation 0.1~10% | |

Automatic voltage adjustment | It can automatically maintain output voltage constant when grid voltage fluctuates. | |

Automatic current adjustment | When the current is over current limit, under clocking automatically limits output current. | |

Function characteristics | Frequency setting mode | Keypad digital analog input, keypad potentiometer, impulse frequency, communication, multi-step speed and simple PLC, PID setting and so on, switch-over of setting modes. |

Simple PLC, multi-step speed control | 16-step speed control | |

Special function | Traverse control, length control, time control | |

QUICK/JOG key | User-defined multi-function hot key | |

Protection function | Over-current, Over voltage, under-voltage, over-heat, phase failure, over-load and motor over-load | |

Working condition | Installation site | Indoor, altitude of less than 1km, dust free, non-corrosive gases, no direct sunlight |

Application environment | -10°C~+40°C, 20~90%RH (no dew) | |

Vibration | Less than 0.5g | |

Storage temperature | -25°C~+65°C | |

Installation type | Wall-mounted type, floor cabinet type | |

Cooling mode | Air-forced cooling | |

- Q: What's the frequency converter for? What does it look like?

- The inverter is mainly used in industrial equipment, such as power plants, water plants, water supply equipment, large pumping station, it is basically a cuboid, a digital display control panel; and in the English show types into the universal type, fan pump type, vector control, different types should be used in different working conditions, voltage grade from 220V-10 million volts, currently has the localization.

- Q: The functions of frequency converter and UPS are similar, especially the power frequency UPS?

- The inverter is actually an inverter. It is the first AC into DC. And then use the electronic element to switch DC power into AC inverter. In general. Large power SCR. And an adjustable frequency. The device can be adjusted in a certain range of frequency is used to control the motor speed. The speed can be adjusted. In a certain range. The inverter is widely used in AC motor speedThe UPS power supply is also called an uninterruptible power supply. An inverter with an adjustable frequency. Battery powered. For short time power supply of computer and other equipment in case of power failure. Prevents sudden power loss and file loss.

- Q: What are the key points of frequency converter maintenance?

- (brief introduction of main circuit of frequency converter)The main circuit of the inverter is composed of four parts: input, rectification, filtering and inverting. The three-phase alternating current is converted into DC through rectification and filtering, and then is converted into three-phase alternating current with arbitrary frequency and voltage. Middle DC link capacitor, due to the large capacitance, DC voltage of the main circuit is relatively stable, the resistance is very small, with the characteristic of the voltage source, a voltage type inverter in the speed control system of asynchronous motor, because the motor is inductive, capacitive reactive power at the same time as a buffer storage component.

- Q: Today, I was asked the question, and I also brought it to you to share the following Oh!

- Inverter inside the circuit is inverterIt is a control of communication -- direct current -- CommunicationDC alternating current is called inverter

- Q: Ask, what is the ratio of frequency converter?

- Three inverter operation indicator light, the output frequency from 0.0Hz to potentiometer set frequency and the output frequency ratio is 1:1.5:2, adjust the tone potentiometer, change the motor speed and the speed of three units, according to the proportion of linkage. The output frequency of the three inverters can be adjusted with three Trimming Potentiometer respectively.

- Q: Why does harmonic generator produce harmonic? What's his working principle?

- Harmonic generation mechanism of converter outputIn the inverter output loop, the output current signal is a pulse waveform modulated by the PWM carrier signal. For GTR high-power inverter component, the carrier frequency of PWM is 2-3kHz, while the maximum carrier frequency of IGBT high-power inverter component is 15kHz, PWM. Similarly, the output loop current signal can also be decomposed into only the fundamental wave and other harmonics.

- Q: How can I control the frequency converter with a computer?

- The commonly used PLC and DCS control system in industrial area are applicable to the conditions of inverter interface control module, can realize the closed-loop converter convenient automatic control in the control system, widely used in large and medium. The control device for some smallexperimental device and embedded processor in inverter control, generally also need to deal with the keyboard input, display, data acquisition and other work such as process control, this control is more suitable for single-chip control system as the core, and uses PLC and operation panel, it can achieve the function but the cost is too high. Should not be used.

- Q: What is the difference between inverter energy consumption braking and motor energy consumption braking?

- Your question, I think it is the difference between regenerative braking and braking of the motor function for active inverter regenerative braking to use inverter feedback power, so there is the braking inverter of the argument?? First of all, define some of your concepts, the motor is divided into reverse braking, energy consumption braking, regenerative braking three. The energy consumption braking of the inverter is called the energy consumption braking by using the braking resistance in the DC loop to absorb the regenerative electric energy of the motor,The utility model has the advantages of simple structure; no pollution to the power grid (for comparison, action and feedback) low cost; the disadvantage is low efficiency, especially to consume a lot of energy and braking resistance will be in frequent braking capacity will increase.

- Q: 5.5KW frequency converter with 4.5KW deep water pump, pressure regulator by conveying signal to frequency converter start normal, the pressure to reduce the frequency converter after the start, to about 30Hz in order to maintain the pressure about shocks, 30 seconds inverter over-current alarm. Can it be the fault of the frequency converter? How should I check it?

- Once the inverter has hardware faults, such as rectifier, inverter circuit and so on. The IGBT module may be damaged, and most of the time it will damage the drive components. The most easily damaged devices are the regulator and the optocoupler. Conversely, components such as capacitance, leakage, breakdown, and optocoupler aging can also cause IGBT modules to burn out or frequency conversion, and output voltage is unbalanced. Check if there is a problem with the drive circuit, and compare the resistance of the trigger terminals when the circuit is not switched on. The voltage waveform at the trigger end can be measured when the power is switched on. However, some inverters are not equipped with modules and can not switch on, when the module P end of the series into a false load, to prevent detection, mistakenly touch the originator or other circuit burned module. In this case, the frequency converter has been seriously damaged (by measuring whether the input and output are short circuited), then there should be special technical personnel maintenance, and generally may not re energized, so as not to expand the scope of failure.

- Q: I would like to ask, the inverter in use in the grid is very high?

- In the process of using inverter, grid voltage fluctuation requirements is not high, the general phase is to allow + 20% fluctuations, three-phase is allowed 15% fluctuations, so most of the grid voltage can be satisfied, unless it is in the countryside, or more remote areas, the voltage change will exceed the allowable value. In addition, the frequency converter on the power grid harmonics also have requirements, if the harmonic content of more than 20%, will lead to frequency converter misoperation, false alarm, more serious circumstances, will lead to inverter out of control, or damage. However, most of the current harmonics will not happen, unless a large number of individual factories use frequency converters, servo, intermediate frequency furnace, welding machine and other equipment.

Send your message to us

China Best Selling VFD Variable Frequency Drive Three Phase 380V

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches