China VFD Frequency Inverter 3 phase input 3 phase output 220V /380V

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.220V Single Phase Variable Frequency Drive 2.2KW

2.Advanced control technology

3.Easy to operate

220V Single Phase Variable Frequency Drive 2.2KW

General

CNBM frequency inverter is a high-quality, multi-function,

low-noise variable frequency drive which is designed, developed and manufactured according to international standards.

It can meet different needs of industrial conditions.

The inverter applies advanced control technology of space voltage vector PWM, with functions of constant voltage control, power-off restart, dead zone compensation, automatic torque compensation, online modification parameter, high-speed impulse input, simple PLC and traverse.

Product Name:CMAX-VCG15/P18.5T3 ~ CMAX-VCG18.5/P22T3

Application

Textile: coarse spinner, spinning frame, wrap-knitting machine, loom, knitting machine, silk-spinning machine, etc.

Plastic: extruder, hauling machine, decorating machine, etc.

Pharmacy: mixer, roaster, etc.

Woodworking: engraving machine, sander, veneer peeling lathe, etc.

Papermaking: single type papermaking machine, etc.

Machine tool: non-core grinding machine, optical lens grinding machine, cutting mill, etc.

Printing: cloth-washing machine, dye vat, etc.

Cement: feeder, air blower, rotary furnace, mixer, crusher, etc

Fan and pump: kinds of fans, blowers and pumps

Specification

Item | Specification | |

Input | Input voltage | 220/380V±15% |

Input frequency | 47~63Hz | |

Output | Output voltage | 0~input voltage |

Output frequency | 0~600Hz | |

Peripheral interface characteristics | Programmable digital input | 4 switch input, 1 high-speed impulse input |

Programmable analog input | AI1: 0~10V input AI2: 0~10V input or 0~20mA input, | |

Programmable open collector output | 2 Output (3.7kW and above: 1 Open collector output) | |

Relay Output | 1 Output (3.7kW and above: 2 Relay output) | |

Analog output | 2 Output, one is 0~10V, another is 0~20mA or 0~10V | |

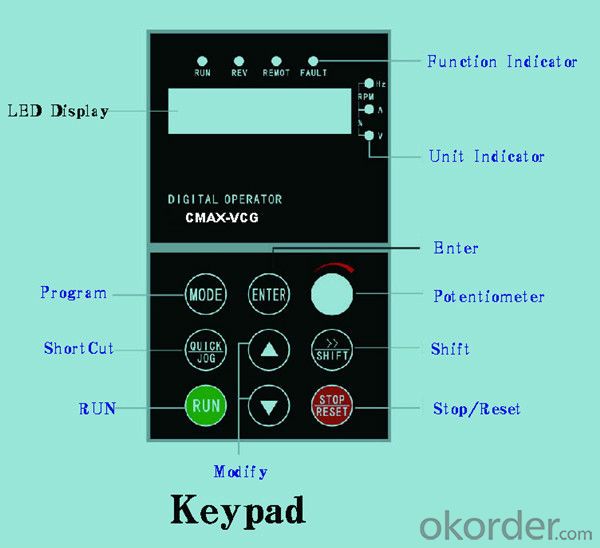

Keypad | Display:5-digit 8-section LED (Red), 2 indicators; parameter setting: 8 keys (including multi-function hot key ), 1 potentiometer | |

Technical performance characteristics | Control mode | All digital space voltage vector SVPWM algorism |

Overload capacity | G purpose: 150% rated current 60s P purpose: 120% rated current 60s | |

Speed ratio | 1: 100 | |

Carrier frequency | 1.0~10.0kHz | |

Torque compensation | Linear, multi-point, 1.3th power, 1.7th power, 2.0th power reduced torque; Compensation voltage range: automatic compensation and manual compensation 0.1~10% | |

Automatic voltage adjustment | It can automatically maintain output voltage constant when grid voltage fluctuates. | |

Automatic current adjustment | When the current is over current limit, under clocking automatically limits output current. | |

Function characteristics | Frequency setting mode | Keypad digital analog input, keypad potentiometer, impulse frequency, communication, multi-step speed and simple PLC, PID setting and so on, switch-over of setting modes. |

Simple PLC, multi-step speed control | 16-step speed control | |

Special function | Traverse control, length control, time control | |

QUICK/JOG key | User-defined multi-function hot key | |

Protection function | Over-current, Over voltage, under-voltage, over-heat, phase failure, over-load and motor over-load | |

Working condition | Installation site | Indoor, altitude of less than 1km, dust free, non-corrosive gases, no direct sunlight |

Application environment | -10°C~+40°C, 20~90%RH (no dew) | |

Vibration | Less than 0.5g | |

Storage temperature | -25°C~+65°C | |

Installation type | Wall-mounted type, floor cabinet type | |

Cooling mode | Air-forced cooling | |

- Q: At the base block Yaskawa inverter is what reason?

- For example: when you put the inverter to stop, there will be a signal to the inverter, then the converter will base the blockade, cut off the output, the motor will no longer work; when you need a converter work, there will be a signal to the inverter, inverter will cancel the locks on the base, and the normal work,This function is only equivalent to one protection.

- Q: Not to say that the inverter speed is mainly down frequency, how can I see the frequency rise to 60HZ, so that the three-phase motor is not more than the rated speed?

- Mainly below the basic frequency of speed regulation,If higher than the basic frequency, that is constant power speed, that is, the higher the motor speed, the smaller the torque

- Q: Where is the difference between soft starter and converter?

- Are two completely different uses of the product. The inverter is used for the need for speed place, its output voltage and frequency change not only change; the soft starter is actually a regulator for motor starting, output voltage and frequency change not only change. Inverters have all of the soft starter functions, but they cost much more than soft starters and have a much more complex structure.

- Q: How does frequency converter realize variable frequency speed regulation?

- V=60f/nvMotor speed fFrequency nMotor poles without frequency converter to change the motor speed, only by changing the pole of the motor to achieve, frequency is 50HZ; through the inverter to change the motor speed is running frequency, no need to replace the motor can realize the speed control. The principle of speed regulation is the formula above.

- Q: Ask, what is the ratio of frequency converter?

- Rotating main potentiometer, respectively, to see the three frequency converter F1.00 parameters, keyboard digital display reference input, follow potentiometer changes, and the proportion of 1:1.5:2. Rotate three trimmer potentiometers respectively, and the reference input of the corresponding converter has little change.

- Q: What are the parameters of the frequency converter? Thank you

- This function is to protect the motor overheating and set up, it is the frequency converter CPU, according to the operation current value and frequency to calculate the temperature rise of the motor, so as to overheat protection. This function is only suitable for "one on one" occasion, and when the "one is more than one", hot relays should be installed on each motor.Electronic thermal protection settings (%) n (A) / motor rated current rated inverter output current (A)] x 100%.

- Q: How to deal with the fault Yaskawa inverter GF

- Inverter display "GF" fault information for ground fault (i.e. the output current exceeds the rated current of the inverter 50%), a power module is reported for G5 damage, may also be a driving circuit, running the report "GF" (the external load is a good case), G5 is PC929 damage. With current detection circuit,

- Q: How can I control the frequency converter with a computer?

- The use of single-chip to control the inverter can choose the last two kinds of methods, the use of communication control, the utility model has the advantages of full control function, suitable for inverter through the level conversion circuit form of communication (RS484/RS232/CAN), you can communicate with the inverter hardware is simple, the number of connections between the two less convenient connection. The disadvantage is that we need to understand the communication protocol of frequency converter to control programming, and the software design is complicated. The inverter communication interface and communication protocol of different brands are different, there is no uniform standard, only for a converter for development, narrowing the selection range of the frequency converter varieties, the applicability is limited. As for the analog input control, can support almost all of the inverter is, although the function is relatively simple, but the main function can realize speed, can meet the use requirements of the majority of occasions, universal.

- Q: What is the TTK converter produced?

- Characteristic:Compact structure design, flexible installation, advanced control algorithm: space voltage vector control technology, power failure restart, automatic voltage adjustment, dead time compensation, energy saving operation,The main and auxiliary setting, built-in PID, simple PLC, oscillating frequency and zero frequency difference, length control, precision control requirements; design and test in accordance with international standards, to ensure the reliability of the product; choose rich accessories.

- Q: Electronic governor for single-phase motor speed control, frequency converter for three-phase motor speed regulation, what are their differences in speed control effect? How does the frequency converter adjust speed? Can you give me an example?

- Is the original power inverter direct input three-phase asynchronous motor inverter in inverter internal access first, through PWM electronic converter technology will AC rectifier, inverter, a controllable frequency alternating current at the input to the motor, the motor operation can be controlled by V/F, output torque control and vector control control frequency, change the loop current, realize energy-saving operation, especially the energy saving effect is obvious in the motor at light load is a kind of energy-saving products, has been widely spread and applied.

Send your message to us

China VFD Frequency Inverter 3 phase input 3 phase output 220V /380V

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords