Frequency Inverter Single-phase 220V class 1.2KW

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.220V Single Phase Variable Frequency Drive 2.2KW

2.Advanced control technology

3.Easy to operate

General

CNBM frequency inverter is a high-quality, multi-function,

low-noise variable frequency drive which is designed, developed and manufactured according to international standards.

It can meet different needs of industrial conditions.

The inverter applies advanced control technology of space voltage vector PWM, with functions of constant voltage control, power-off restart, dead zone compensation, automatic torque compensation, online modification parameter, high-speed impulse input, simple PLC and traverse.

Product Name:CMAX-VCG15/P18.5T3 ~ CMAX-VCG18.5/P22T3

Application

Textile: coarse spinner, spinning frame, wrap-knitting machine, loom, knitting machine, silk-spinning machine, etc.

Plastic: extruder, hauling machine, decorating machine, etc.

Pharmacy: mixer, roaster, etc.

Woodworking: engraving machine, sander, veneer peeling lathe, etc.

Papermaking: single type papermaking machine, etc.

Machine tool: non-core grinding machine, optical lens grinding machine, cutting mill, etc.

Printing: cloth-washing machine, dye vat, etc.

Cement: feeder, air blower, rotary furnace, mixer, crusher, etc

Fan and pump: kinds of fans, blowers and pumps

Specification

Item | Specification | |

Input | Input voltage | 220/380V±15% |

Input frequency | 47~63Hz | |

Output | Output voltage | 0~input voltage |

Output frequency | 0~600Hz | |

Peripheral interface characteristics | Programmable digital input | 4 switch input, 1 high-speed impulse input |

Programmable analog input | AI1: 0~10V input AI2: 0~10V input or 0~20mA input, | |

Programmable open collector output | 2 Output (3.7kW and above: 1 Open collector output) | |

Relay Output | 1 Output (3.7kW and above: 2 Relay output) | |

Analog output | 2 Output, one is 0~10V, another is 0~20mA or 0~10V | |

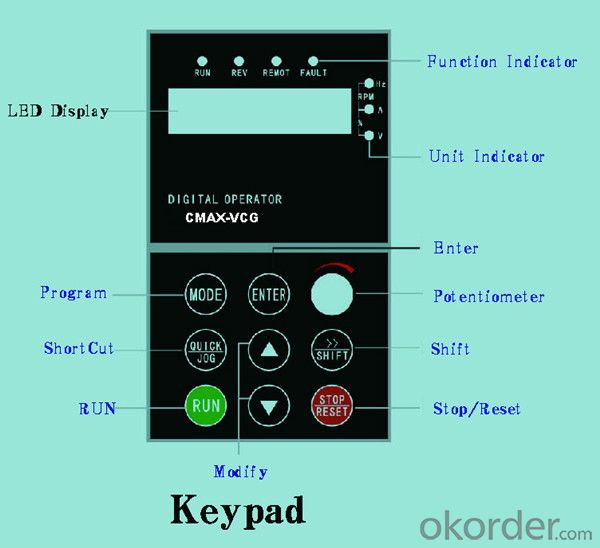

Keypad | Display:5-digit 8-section LED (Red), 2 indicators; parameter setting: 8 keys (including multi-function hot key ), 1 potentiometer | |

Technical performance characteristics | Control mode | All digital space voltage vector SVPWM algorism |

Overload capacity | G purpose: 150% rated current 60s P purpose: 120% rated current 60s | |

Speed ratio | 1: 100 | |

Carrier frequency | 1.0~10.0kHz | |

Torque compensation | Linear, multi-point, 1.3th power, 1.7th power, 2.0th power reduced torque; Compensation voltage range: automatic compensation and manual compensation 0.1~10% | |

Automatic voltage adjustment | It can automatically maintain output voltage constant when grid voltage fluctuates. | |

Automatic current adjustment | When the current is over current limit, under clocking automatically limits output current. | |

Function characteristics | Frequency setting mode | Keypad digital analog input, keypad potentiometer, impulse frequency, communication, multi-step speed and simple PLC, PID setting and so on, switch-over of setting modes. |

Simple PLC, multi-step speed control | 16-step speed control | |

Special function | Traverse control, length control, time control | |

QUICK/JOG key | User-defined multi-function hot key | |

Protection function | Over-current, Over voltage, under-voltage, over-heat, phase failure, over-load and motor over-load | |

Working condition | Installation site | Indoor, altitude of less than 1km, dust free, non-corrosive gases, no direct sunlight |

Application environment | -10°C~+40°C, 20~90%RH (no dew) | |

Vibration | Less than 0.5g | |

Storage temperature | -25°C~+65°C | |

Installation type | Wall-mounted type, floor cabinet type | |

Cooling mode | Air-forced cooling | |

- Q:At the base block Yaskawa inverter is what reason?

- Garbage in Yaskawa signal board on the small line contact oxidation, look good, this is a kind of weak signal, and for safety relay is not the safety loop at high levels in a small line short circuit, 1000 Yaskawa A factory is shorted for a long time have blocked the oxidation base

- Q:That is, some parameters of the inverter, such as torque, current, frequency, etc., are displayed on the Kingview software interface, but not through the PLC. The idea that the MODBUS protocol between SIEMENS and 200PLC has never been successful before, so that's the idea of the ABB. If it can be achieved,Is it necessary to write the script program on the Kingview, and what problems should I pay attention to when using the MODBUS protocol in Kingview software?The problem is a little bit more, I hope the experts teach me this rookie! Thank you

- ABB converter supports MODBUS protocol, can be directly connected to the ModbusRTU in your choice of Kingview, device configuration, set up converter address directly in Kingview read the corresponding parameters can be

- Q:Today, I was asked the question, and I also brought it to you to share the following Oh!

- The frequency of the electricity we use everyday is 50Hz. If we want to change the frequency, we have to change it through the frequency converter.The working principle of frequency converter is to change the frequency alternating current into no frequency direct current, and then control it by electronic circuit so that it can adjust its frequency alternating current at any time.The inverter is similar to the back half of the inverter, which converts the direct current into alternating current.

- Q:What is the main harmonic produced by a transducer? How about the degree?

- To reduce the influence of harmonics, various measures can be taken, but for the inverter, the main circuit is to install an AC reactor.The input side of the inverter generates the harmonic mechanism: for the inverter, as long as there is a rectifier circuit on the power supply side, it will produce harmonics caused by nonlinearity. Based on the three-phase bridge rectifier circuit for example, AC grid voltage for a sine wave, square wave AC input current waveform, the waveform, according to Fourier series can be decomposed into fundamental and harmonics, usually containing 6m + 1 (m=1,2) harmonics, the harmonics in power grid. A single fundamental wave, combined with several harmonic waves, is called an abnormal wave

- Q:Does the number of inverter settings differ from the number of motor poles, and does it affect the use?

- Frequency converter has a number of requirements, if the motor is not set by the number of motor parameters, I think there will be the following problems, but may occur, I have not been verified:

- Q:What are the parameters of the frequency converter? Thank you

- Inverter function parameters are many, generally have ten, or even hundreds of parameters for users to choose. In practical applications, it is not necessary to set and debug each parameter, most of which can only be used as factory settings. But some parameters have great relationship with the actual use, and some are related to each other, so they should be set and debugged according to the actual situation.Because of the type of converter function are different, but the same function parameter name is not consistent, but the type of converter is almost always some basic parameters, can be done completely by analogy. The following parameters are basically used:

- Q:If you don't plug in the PG card, do you use PLC's PID control?Plug in the PG card and the PLC PID control, which is reliable and precise?

- If there is a PLC encoder as a speed sensor signal, you can access the PLCPLC analog output (or communication) as a given value of the inverterUse PLC's PID instruction to complete the speed closed loop control of the converter.Note: if you are not using vector control of the inverter, you can.For example: horizontal transmission of non vector control or pump fan class.

- Q:The frequency converter is in use suddenly the speed reduces, then the debugging is out of control, how to do?

- Among them, overvoltage is the most common phenomenon. After the overvoltage is generated, the inverter will prevent the internal circuit from damaging, and its over-voltage protection function will make the inverter stop running, resulting in the equipment can not work properly. Therefore, measures must be taken to eliminate excessive voltage and prevent the occurrence of faults. As the frequency converter and motor applications are different, the causes of over-voltage are not the same, so we should take appropriate countermeasures according to specific circumstances.

- Q:What are the possible causes of frequency hopping overload?

- Because the overload is judged only by the current, it will happen at the start, stop, acceleration and deceleration, and constant speed operation. Moreover, the current and the asynchronous motor difference are inseparable, so the following conditions can be used for analysis and reference:

- Q:What is a frequency converter?

- Frequency conversion technology is born with the need of AC motor stepless speed regulation. After 1960s, the power electronic devices through SCR (SCR), GTO (gate turn off thyristor (BJT), bipolar power transistor), MOSFET (metal oxide semiconductor field effect transistor), SIT (static induction transistor), SITH (static induction thyristor (MGT), MOS control MCT (MOS) transistor, thyristor controlled), IGBT (insulated gate bipolar transistor), HVIGBT (high voltage insulated gate bipolar transistor) device to update the development process, to promote the continuous development of power electronics technology. The beginning of 1970s, PWM VVVF (PWMVVVF) control has aroused great attention. In 1980s, PWM mode optimization, as the core of frequency conversion technology, attracted people's interest and obtained many optimization models, among which the saddle wave PWM model was the best. Since the latter half of the 1980s, the VVVF inverters in developed countries such as the United States, Japan, Germany, Britain and other developed countries have already been put into the market and have been widely used.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Frequency Inverter Single-phase 220V class 1.2KW

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords