Frequency Inverter Single-phase 220V class 75KW

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General

CNBM frequency inverter is a high-quality, multi-function,

low-noise variable frequency drive which is designed, developed and manufactured according to international standards.

It can meet different needs of industrial conditions.

The inverter applies advanced control technology of space voltage vector PWM, with functions of constant voltage control, power-off restart, dead zone compensation, automatic torque compensation, online modification parameter, high-speed impulse input, simple PLC and traverse.

Application

Textile: coarse spinner, spinning frame, wrap-knitting machine, loom, knitting machine, silk-spinning machine, etc.

Plastic: extruder, hauling machine, decorating machine, etc.

Pharmacy: mixer, roaster, etc.

Woodworking: engraving machine, sander, veneer peeling lathe, etc.

Papermaking: single type papermaking machine, etc.

Machine tool: non-core grinding machine, optical lens grinding machine, cutting mill, etc.

Printing: cloth-washing machine, dye vat, etc.

Cement: feeder, air blower, rotary furnace, mixer, crusher, etc

Fan and pump: kinds of fans, blowers and pumps

Specification

Item | Specification | |

Input | Input voltage | 220/380V±15% |

Input frequency | 47~63Hz | |

Output | Output voltage | 0~input voltage |

Output frequency | 0~600Hz | |

Peripheral interface characteristics | Programmable digital input | 4 switch input, 1 high-speed impulse input |

Programmable analog input | AI1: 0~10V input AI2: 0~10V input or 0~20mA input, | |

Programmable open collector output | 2 Output (3.7kW and above: 1 Open collector output) | |

Relay Output | 1 Output (3.7kW and above: 2 Relay output) | |

Analog output | 2 Output, one is 0~10V, another is 0~20mA or 0~10V | |

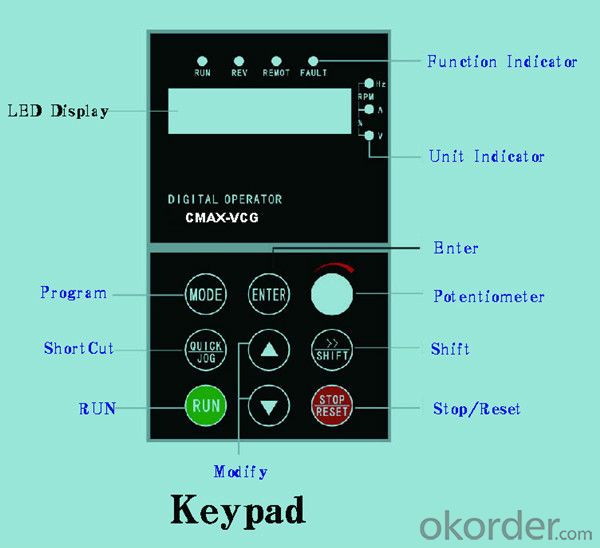

Keypad | Display:5-digit 8-section LED (Red), 2 indicators; parameter setting: 8 keys (including multi-function hot key ), 1 potentiometer | |

Technical performance characteristics | Control mode | All digital space voltage vector SVPWM algorism |

Overload capacity | G purpose: 150% rated current 60s P purpose: 120% rated current 60s | |

Speed ratio | 1: 100 | |

Carrier frequency | 1.0~10.0kHz | |

Torque compensation | Linear, multi-point, 1.3th power, 1.7th power, 2.0th power reduced torque; Compensation voltage range: automatic compensation and manual compensation 0.1~10% | |

Automatic voltage adjustment | It can automatically maintain output voltage constant when grid voltage fluctuates. | |

Automatic current adjustment | When the current is over current limit, under clocking automatically limits output current. | |

Function characteristics | Frequency setting mode | Keypad digital analog input, keypad potentiometer, impulse frequency, communication, multi-step speed and simple PLC, PID setting and so on, switch-over of setting modes. |

Simple PLC, multi-step speed control | 16-step speed control | |

Special function | Traverse control, length control, time control | |

QUICK/JOG key | User-defined multi-function hot key | |

Protection function | Over-current, Over voltage, under-voltage, over-heat, phase failure, over-load and motor over-load | |

Working condition | Installation site | Indoor, altitude of less than 1km, dust free, non-corrosive gases, no direct sunlight |

Application environment | -10°C~+40°C, 20~90%RH (no dew) | |

Vibration | Less than 0.5g | |

Storage temperature | -25°C~+65°C | |

Installation type | Wall-mounted type, floor cabinet type | |

Cooling mode | Air-forced cooling | |

- Q:It was when processing a workpiece, processing spindle stops suddenly (other are normal) a check is, I jump out of the inverter, I can click on a processing, and then processing not long after they happen, (do not open the machine spindle machining will also be the case)

- It should be a frequency converter. Right now, look at the frequency converter output frequency settings, tune, and suggest the next election wide output frequency converter, or simply PLC

- Q:What does 0L1 stand for?

- The acceleration is generally overloaded during acceleration. Load inertia is too large, the inverter power is small, or the acceleration time is too short, and so on

- Q:What's the difference between universal inverter and fan pump converter?

- Fan and pump load:In a variety of fans, pumps, oil pumps, with the rotation of the impeller, the air or liquid within a certain speed range of resistance is roughly proportional to the speed of the 2 side of the n. As the speed decreases, the torque decreases by 2 times the speed. The power required for this kind of load is proportional to the 3 power of the velocity. When the required air volume and flow rate are reduced, the frequency and speed of air flow can be regulated by the frequency converter, so the energy can be saved substantially. Because the power required at high speed increases with the speed, and is proportional to the speed of the three side, so the fan and pump load should not be used in the ultra power frequency operation

- Q:What does the RUN key on the inverter mean? How do you use it?

- In general, when selecting panel operations (when the panel of the inverter is the control source of the inverter), it is the meaning of the "running" button. Press it, the converter will run, turn or reverse

- Q:How does the frequency converter fit the brake unit and the brake resistor?!

- To calculate how much energy consumption, can be converted into electric current, to select the brake unit. You can also choose the braking resistance (to consider resistance temperature characteristics to choose), then select the brake unit with matching (see manufacturer manual).

- Q:Why does the frequency converter cause interference?

- (a) PE converter main circuit terminals (E, G) must be grounded, the motor can be grounded and the inverter with the common ground, but not with other equipment, must play ground pile, and the ground should take place far away from electrical equipment. At the same time, the cross-sectional area of the grounding wire of the converter shall be no less than 4mm2, and the length shall be within 20m.(b) in the ground wire of other electromechanical equipment, the protective earthing and the work earthing shall be separately provided with grounding electrodes, and finally shall be imported to the electrical position of the distribution cabinet. The shield of the control signal and the shielding of the main circuit wire shall also be separately provided with earth electrodes, and finally shall be incorporated into the electrical junction of the distribution cabinet.

- Q:How to maintain the frequency converter will not damage, or regular maintenance?

- If the conditions permit, use the oscilloscope to measure the stability of the switching power supply output voltage, such as: 5V, 12V, 15V, 24V and other voltage. Is there any distortion in the square wave of the measuring circuit?. Periodic inspection is recommended and shall be conducted once a year.

- Q:What is the over-current of the inverter?

- External cause:?1, the motor load mutation caused by excessive impact, resulting in excessive flow.?2, the motor and motor cable phase or insulation damage to each other, resulting in short circuit turns to the ground, resulting in over-current.?3, over-current fault and motor leakage reactance, motor cable coupling reactance, so choose motor cable must be selected according to requirements.?4. Power factor correction capacitor or surge absorption device on the output side of inverter.?5. When the speed feedback signal is lost or abnormal, it will cause excessive flow, and check the encoder and its cable.

- Q:How much is the motor 90KW and the frequency converter selected?Colleagues suggest 110W?The cost will be higherIs it okay to choose 90KW?

- You refer to the type and parameters of the frequency changer to select.

- Q:What are the possible causes of frequency hopping overload?

- Because the overload is judged only by the current, it will happen at the start, stop, acceleration and deceleration, and constant speed operation. Moreover, the current and the asynchronous motor difference are inseparable, so the following conditions can be used for analysis and reference:

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Frequency Inverter Single-phase 220V class 75KW

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords