Frequency Inverter Single-phase 380V class 185KW

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General

CNBM frequency inverter is a high-quality, multi-function,

low-noise variable frequency drive which is designed, developed and manufactured according to international standards.

It can meet different needs of industrial conditions.

The inverter applies advanced control technology of space voltage vector PWM, with functions of constant voltage control, power-off restart, dead zone compensation, automatic torque compensation, online modification parameter, high-speed impulse input, simple PLC and traverse.

Product Name:CMAX-VCG15/P18.5T3 ~ CMAX-VCG18.5/P22T3

Application

Textile: coarse spinner, spinning frame, wrap-knitting machine, loom, knitting machine, silk-spinning machine, etc.

Plastic: extruder, hauling machine, decorating machine, etc.

Pharmacy: mixer, roaster, etc.

Woodworking: engraving machine, sander, veneer peeling lathe, etc.

Papermaking: single type papermaking machine, etc.

Machine tool: non-core grinding machine, optical lens grinding machine, cutting mill, etc.

Printing: cloth-washing machine, dye vat, etc.

Cement: feeder, air blower, rotary furnace, mixer, crusher, etc

Fan and pump: kinds of fans, blowers and pumps

Specification

Item | Specification | |

Input | Input voltage | 220/380V±15% |

Input frequency | 47~63Hz | |

Output | Output voltage | 0~input voltage |

Output frequency | 0~600Hz | |

Peripheral interface characteristics | Programmable digital input | 4 switch input, 1 high-speed impulse input |

Programmable analog input | AI1: 0~10V input AI2: 0~10V input or 0~20mA input, | |

Programmable open collector output | 2 Output (3.7kW and above: 1 Open collector output) | |

Relay Output | 1 Output (3.7kW and above: 2 Relay output) | |

Analog output | 2 Output, one is 0~10V, another is 0~20mA or 0~10V | |

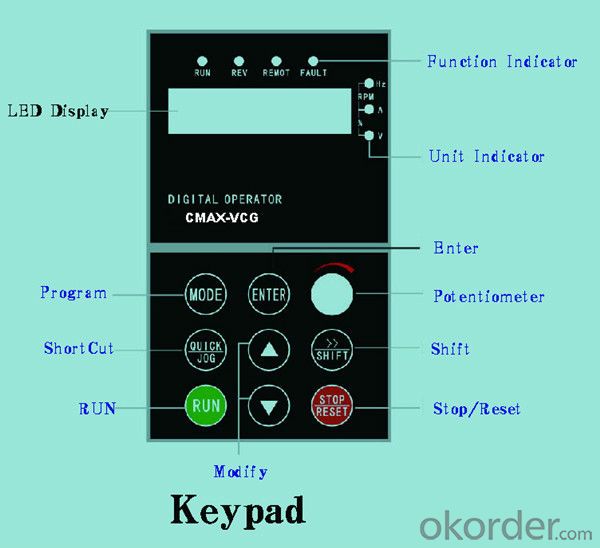

Keypad | Display:5-digit 8-section LED (Red), 2 indicators; parameter setting: 8 keys (including multi-function hot key ), 1 potentiometer | |

Technical performance characteristics | Control mode | All digital space voltage vector SVPWM algorism |

Overload capacity | G purpose: 150% rated current 60s P purpose: 120% rated current 60s | |

Speed ratio | 1: 100 | |

Carrier frequency | 1.0~10.0kHz | |

Torque compensation | Linear, multi-point, 1.3th power, 1.7th power, 2.0th power reduced torque; Compensation voltage range: automatic compensation and manual compensation 0.1~10% | |

Automatic voltage adjustment | It can automatically maintain output voltage constant when grid voltage fluctuates. | |

Automatic current adjustment | When the current is over current limit, under clocking automatically limits output current. | |

Function characteristics | Frequency setting mode | Keypad digital analog input, keypad potentiometer, impulse frequency, communication, multi-step speed and simple PLC, PID setting and so on, switch-over of setting modes. |

Simple PLC, multi-step speed control | 16-step speed control | |

Special function | Traverse control, length control, time control | |

QUICK/JOG key | User-defined multi-function hot key | |

Protection function | Over-current, Over voltage, under-voltage, over-heat, phase failure, over-load and motor over-load | |

Working condition | Installation site | Indoor, altitude of less than 1km, dust free, non-corrosive gases, no direct sunlight |

Application environment | -10°C~+40°C, 20~90%RH (no dew) | |

Vibration | Less than 0.5g | |

Storage temperature | -25°C~+65°C | |

Installation type | Wall-mounted type, floor cabinet type | |

Cooling mode | Air-forced cooling | |

- Q: When the inverter is running at full 50HZ, the output voltage decreases and the output current becomes smaller. What is the reason?

- I don't know if you're a manufacturer of car gearboxes, and we've also done car engine tests. The operation in the 50HZ when the inverter is not reduced voltage, if only a little decrease will decrease, this is due to increasing frequency, controllable silicon resistance increases, the corresponding motor voltage decreased slightly, not what the essence of influence.

- Q: The functions of frequency converter and UPS are similar, especially the power frequency UPS?

- The obvious difference between the two:1, the former output amplitude and frequency adjustable, the latter output is a single fixed amplitude, frequency;2, the former does not use batteries, and the latter requires batteries.

- Q: Not to say that the inverter speed is mainly down frequency, how can I see the frequency rise to 60HZ, so that the three-phase motor is not more than the rated speed?

- When the high speed motor is driven by a transducer, the higher the higher harmonic is, the higher the output current value is due to the small reactance of the high speed motor. Therefore, the type selection of frequency converter used in high speed motor is slightly larger than the selection of ordinary motor.And if you want a long cable converter operation, this time to take measures to curb the influence of long cable on the coupling capacitor, to avoid the shortage of inverter output, so in this case, the frequency converter to enlarge the capacity of a file or install the output reactor in the inverter output.And for some special applications, such as high temperature, high altitude, at this time will cause the inverter derating, frequency converter to enlarge the capacity of a block.

- Q: There is a feed and send system. Now due to the severity of the material is not the same as the two converters often change speed, the workers do not understand their own, often by, often bad now how to use the best way you can use a potentiometer or other method, control of the two frequency converter, synchronous operation. Is to adjust one, and the other also with the kind of frequency, so that you can let the workers themselves to open, and the two inverters, the same manufacturer, the same model, the same load,

- What kind of communication mode does the frequency converter support? Generally speaking, it is more accurate to communicate by means of synchronization. Expensive。The main transformer potentiometer, from the analog frequency converter, may be 1, the lag will be greater than 2, analog may have a larger error, 3, analog may be subject to interference. The cheapest。You can also use synchronous controller, analog input, the two roads as the same analog, cheaper, more reliable synchronization, may be disturbed.

- Q: Where is the frequency converter used?

- The machinery manufacturing industry, including: elevator, automobile, textile, printing and packaging, paper making, hoisting machinery, food, tobacco, etc. the use of these pumps, inverter industry is mainly in electrical equipment, control and obtain the best product performance and output rate is the main purpose of energy saving is different from the 1 in

- Q: The difference between soft starter and converter

- The soft starter is just a thyristor pressure regulating device is simple to start the motor, the motor speed can not be normal, low price; inverter is the AC power supply voltage and frequency, can IGBT chopper can be used to start the motor, can also be normal speed, the price is relatively expensive

- Q: Why does harmonic generator produce harmonic? What's his working principle?

- Harmonic generation mechanism of inverter inputThe main circuit of inverter is composed of AC-DC-AC, external input 380V/50Hz power supply through the three-phase bridge rectifier, a DC voltage, AC voltage by the capacitor filter and high power transistor switching element for variable frequency inverter. In the rectifying circuit, the input current waveform is a rectangular wave irregular waveform, according to Fu Liye series is decomposed into fundamental and harmonics, the harmonic frequency is usually 6N + 1 harmonic, the harmonic interference input power supply system. If the reactance of the supply side is sufficiently small and the commutation overlap angle can be neglected, then the n order harmonic is the 1/n of the fundamental current.

- Q: Can the motor with frequency converter directly wave the insulation?

- May notBecause the shaking meter used when shaking insulation, although the output is direct current, but after conversion, the voltage will exceed the rated voltage of the motor much, the only way to test the motor winding to the ground and interphase insulation.

- Q: Frequency converter OC alarm, what's the matter?

- And some did not inform you of the inverter fault category, when the OC boot failure, will cause greater danger, then simply caused by surface phenomenon similar to program crashes, such as the P9/G9 series machine when the machine detects INVT, module failure, operationThe H00 character appears on the panel, and all key actions are rejected. Unknown insider will think: program crash, CPU motherboard is a problem.

- Q: Which brand of converter is better?

- Shanghai international shipping center Yangshan deep water port project, Shanghai Pudong Airport, Shanghai Hongqiao Airport, the Three Gorges project, Gansu satellite launch center, the south to North Water Diversion, the west east gas transmission, China Petroleum group,

Send your message to us

Frequency Inverter Single-phase 380V class 185KW

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords