Frequency Inverter Single-phase 380V class 125KW

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.380V Single Phase Variable Frequency Drive 125KW

2.Advanced control technology

3.Easy to operate

General

CNBM frequency inverter is a high-quality, multi-function,

low-noise variable frequency drive which is designed, developed and manufactured according to international standards.

It can meet different needs of industrial conditions.

The inverter applies advanced control technology of space voltage vector PWM, with functions of constant voltage control, power-off restart, dead zone compensation, automatic torque compensation, online modification parameter, high-speed impulse input, simple PLC and traverse.

Product Name:CMAX-VCG15/P18.5T3 ~ CMAX-VCG18.5/P22T3

Application

Textile: coarse spinner, spinning frame, wrap-knitting machine, loom, knitting machine, silk-spinning machine, etc.

Plastic: extruder, hauling machine, decorating machine, etc.

Pharmacy: mixer, roaster, etc.

Woodworking: engraving machine, sander, veneer peeling lathe, etc.

Papermaking: single type papermaking machine, etc.

Machine tool: non-core grinding machine, optical lens grinding machine, cutting mill, etc.

Printing: cloth-washing machine, dye vat, etc.

Cement: feeder, air blower, rotary furnace, mixer, crusher, etc

Fan and pump: kinds of fans, blowers and pumps

Specification

Item | Specification | |

Input | Input voltage | 220/380V±15% |

Input frequency | 47~63Hz | |

Output | Output voltage | 0~input voltage |

Output frequency | 0~600Hz | |

Peripheral interface characteristics | Programmable digital input | 4 switch input, 1 high-speed impulse input |

Programmable analog input | AI1: 0~10V input AI2: 0~10V input or 0~20mA input, | |

Programmable open collector output | 2 Output (3.7kW and above: 1 Open collector output) | |

Relay Output | 1 Output (3.7kW and above: 2 Relay output) | |

Analog output | 2 Output, one is 0~10V, another is 0~20mA or 0~10V | |

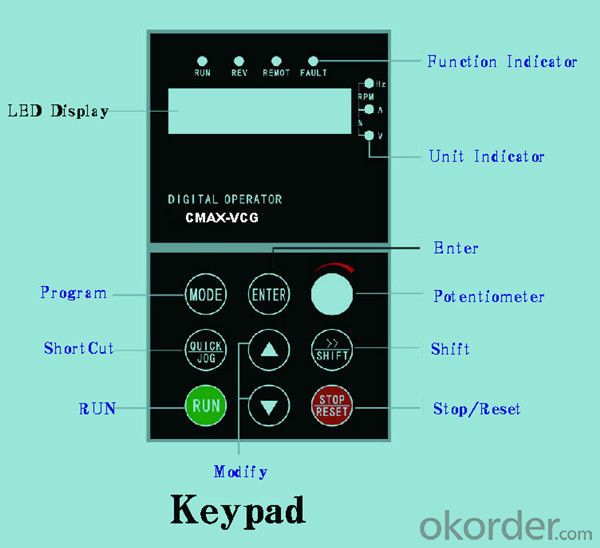

Keypad | Display:5-digit 8-section LED (Red), 2 indicators; parameter setting: 8 keys (including multi-function hot key ), 1 potentiometer | |

Technical performance characteristics | Control mode | All digital space voltage vector SVPWM algorism |

Overload capacity | G purpose: 150% rated current 60s P purpose: 120% rated current 60s | |

Speed ratio | 1: 100 | |

Carrier frequency | 1.0~10.0kHz | |

Torque compensation | Linear, multi-point, 1.3th power, 1.7th power, 2.0th power reduced torque; Compensation voltage range: automatic compensation and manual compensation 0.1~10% | |

Automatic voltage adjustment | It can automatically maintain output voltage constant when grid voltage fluctuates. | |

Automatic current adjustment | When the current is over current limit, under clocking automatically limits output current. | |

Function characteristics | Frequency setting mode | Keypad digital analog input, keypad potentiometer, impulse frequency, communication, multi-step speed and simple PLC, PID setting and so on, switch-over of setting modes. |

Simple PLC, multi-step speed control | 16-step speed control | |

Special function | Traverse control, length control, time control | |

QUICK/JOG key | User-defined multi-function hot key | |

Protection function | Over-current, Over voltage, under-voltage, over-heat, phase failure, over-load and motor over-load | |

Working condition | Installation site | Indoor, altitude of less than 1km, dust free, non-corrosive gases, no direct sunlight |

Application environment | -10°C~+40°C, 20~90%RH (no dew) | |

Vibration | Less than 0.5g | |

Storage temperature | -25°C~+65°C | |

Installation type | Wall-mounted type, floor cabinet type | |

Cooling mode | Air-forced cooling | |

- Q: Frequency converter, fault, contact action

- The frequency converter has 1-2 relay outputs, that is, digital output. By default, most of the output of the fault is the relay. The general definition of the 2 relays is defined as a running output and a fault output.

- Q: What's the use of switching frequency of converter?

- Very important!The higher the switching frequency is, the smaller the harmonic is when the output waveform passes through the motor winding. The reason is that the higher the switching frequency is, the higher the harmonic frequency is, the higher the harmonic impedance is, and the smaller the harmonic current is. The smaller the harmonic current is, the smaller the harmonic loss is and the smaller the torque ripple is, the better the motor performance is.However, the higher the switching frequency, the greater the frequency converter loss, the lower the efficiency of the inverter, and more importantly, the greater the heat, the inverter may not be able to bear.In addition, according to the fundamental frequency of operation, the switching frequency is preferably an integer multiple of the fundamental frequency, and this multiple is an integer multiple of 3, which can effectively reduce the low harmonics which affect the motor greatly!

- Q: What is the main function of the frequency converter on the machine tools?

- The following example to three inverter in the application of the note for example!CNC machine tool is a kind of flexible and efficient automatic machine tool. It can solve the complicated, precise and small batch processing problem. It is very important to improve the machining accuracy and efficiency of CNC machine tools by rationally controlling the spindle of NC machine tools.

- Q: Ask, what is the ratio of frequency converter?

- Connect the air switch, the power supply, check the wiring is correct, close the air switch, turn on the frequency converter, and the digital tube shows 0.Turn off the power, the power indicator light is extinguished, then connect the motor, on-off switch, tone potentiometer, trimmer potentiometer, inching button, frequency meter (0 ~ 10V voltage meter), three sets of inverter and motor proportion of joint operation, the inverter and the motor grounding terminal reliable grounding, and carefully check.

- Q: What is called vector converter?

- The vector is what we (the mainland) says. The vector is generally used in the literature of Hong Kong and Taiwan. The meaning is roughly the same as that of Bush and bush. Vector control is mainly a concept of decoupling of motor models

- Q: What's the function of this brake unit?

- In order to digest this part of the energy, the transducer consumes the energy of the feedback current through the resistor.If the inverter is more advanced, this part of the current can also be sent to the call back network through the controlled rectifier bridge. There's no braking resistance.

- Q: Why does the frequency change when the frequency converter regulates the frequency?

- Because the product of three-phase asynchronous motor stator phase voltage and frequency and flux is proportional to the frequency when the downward adjustment, if the sustain voltage is constant, the flux must be increased, this will cause the main magnetic saturation excitation current passing, the surge in motor damage.As a result, the voltage is usually adjusted down proportionally as the frequency is lowered down.However, when adjusting the frequency, the voltage is not adjustable in order to avoid the excessive voltage damage of the motor. Therefore, in the use of frequency converter overclocking motor, the magnetic flux will decline, the motor output torque characteristics will move to the left.

- Q: How do two inverters synchronize?

- One potentiometer is used to control one of the inverters, and then the analog output of the inverter is used to control another inverter, and a potentiometer is added to the middle of the converter to adjust the proportion.

- Q: How can I control the frequency converter with a computer?

- The commonly used PLC and DCS control system in industrial area are applicable to the conditions of inverter interface control module, can realize the closed-loop converter convenient automatic control in the control system, widely used in large and medium. The control device for some smallexperimental device and embedded processor in inverter control, generally also need to deal with the keyboard input, display, data acquisition and other work such as process control, this control is more suitable for single-chip control system as the core, and uses PLC and operation panel, it can achieve the function but the cost is too high. Should not be used.

- Q: What is the frequency converter AVR?

- AVR is the abbreviation of "Automatic voltage regulator", which means automatic voltage regulation".The general frequency converter with this function, when the input voltage changes, DC bus voltage of the inverter will also change, real-time detection of the bus voltage controller, according to the change of output bus voltage modulation ratio, the output voltage is relatively stable.

Send your message to us

Frequency Inverter Single-phase 380V class 125KW

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords