AC Driver China Best Selling VFD Frequency Drive 3 phase 380V 11kw

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.220V Single Phase Variable Frequency Drive 2.2KW

2.Advanced control technology

3.Easy to operate

220V Single Phase Variable Frequency Drive 2.2KW

General

CNBM frequency inverter is a high-quality, multi-function,

low-noise variable frequency drive which is designed, developed and manufactured according to international standards.

It can meet different needs of industrial conditions.

The inverter applies advanced control technology of space voltage vector PWM, with functions of constant voltage control, power-off restart, dead zone compensation, automatic torque compensation, online modification parameter, high-speed impulse input, simple PLC and traverse.

Specification

Item | Specification | |

Input | Input voltage | 220/380V±15% |

Input frequency | 47~63Hz | |

Output | Output voltage | 0~input voltage |

Output frequency | 0~600Hz | |

Peripheral interface characteristics | Programmable digital input | 4 switch input, 1 high-speed impulse input |

Programmable analog input | AI1: 0~10V input AI2: 0~10V input or 0~20mA input, | |

Programmable open collector output | 2 Output (3.7kW and above: 1 Open collector output) | |

Relay Output | 1 Output (3.7kW and above: 2 Relay output) | |

Analog output | 2 Output, one is 0~10V, another is 0~20mA or 0~10V | |

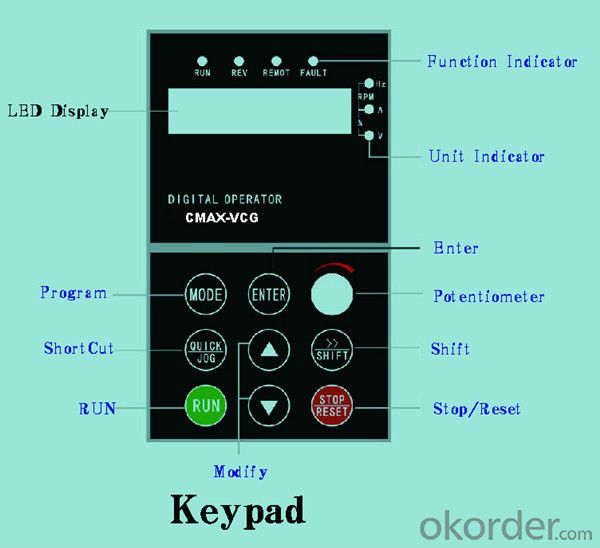

Keypad | Display:5-digit 8-section LED (Red), 2 indicators; parameter setting: 8 keys (including multi-function hot key ), 1 potentiometer | |

Technical performance characteristics | Control mode | All digital space voltage vector SVPWM algorism |

Overload capacity | G purpose: 150% rated current 60s P purpose: 120% rated current 60s | |

Speed ratio | 1: 100 | |

Carrier frequency | 1.0~10.0kHz | |

Torque compensation | Linear, multi-point, 1.3th power, 1.7th power, 2.0th power reduced torque; Compensation voltage range: automatic compensation and manual compensation 0.1~10% | |

Automatic voltage adjustment | It can automatically maintain output voltage constant when grid voltage fluctuates. | |

Automatic current adjustment | When the current is over current limit, under clocking automatically limits output current. | |

Function characteristics | Frequency setting mode | Keypad digital analog input, keypad potentiometer, impulse frequency, communication, multi-step speed and simple PLC, PID setting and so on, switch-over of setting modes. |

Simple PLC, multi-step speed control | 16-step speed control | |

Special function | Traverse control, length control, time control | |

QUICK/JOG key | User-defined multi-function hot key | |

Protection function | Over-current, Over voltage, under-voltage, over-heat, phase failure, over-load and motor over-load | |

Working condition | Installation site | Indoor, altitude of less than 1km, dust free, non-corrosive gases, no direct sunlight |

Application environment | -10°C~+40°C, 20~90%RH (no dew) | |

Vibration | Less than 0.5g | |

Storage temperature | -25°C~+65°C | |

Installation type | Wall-mounted type, floor cabinet type | |

Cooling mode | Air-forced cooling | |

Application

Textile: coarse spinner, spinning frame, wrap-knitting machine, loom, knitting machine, silk-spinning machine, etc.

Plastic: extruder, hauling machine, decorating machine, etc.

Pharmacy: mixer, roaster, etc.

Woodworking: engraving machine, sander, veneer peeling lathe, etc.

Papermaking: single type papermaking machine, etc.

Machine tool: non-core grinding machine, optical lens grinding machine, cutting mill, etc.

Printing: cloth-washing machine, dye vat, etc.

Cement: feeder, air blower, rotary furnace, mixer, crusher, etc

Fan and pump: kinds of fans, blowers and pumps

- Q: A control panel I received a photoelectric switch, through the 232 interface connected to the computer, control with a 220V power supply board, computer and inverter when the inverter after the start of the photoelectric switch either do not work or turn off the flash chaos, frequency converter or 232 line open photoelectric switch will be back to normal work. In addition, when the photoelectric switch is powered separately, if the ground wire is connected to the control board, the photoelectric switch does not work. Excuse me, is this interference from the power cord? How to solve?

- Reasonable wiring: the concrete method has:The power line and signal line of the equipment shall be as far as possible from the input and output lines of the converter.Other equipment power lines and signal lines should be avoided parallel with the input and output lines of the inverter.If the above measures are not successful, then continue the following measures:

- Q: 1, the frequency converter to the motor cable should be shielded cable? 2, whether there are specifications?

- When we design the frequency converter to drag the motor load (mostly fan and water pump general machine), we should use shielded cable. We refer to the GB/T21209-2007 "inverter power supply design and performance of cage induction motors in section 9.1.4" guide "motor power cable" 9.1.4.1 "recommended configuration" in the "provisions of more than 30kW motor wiring should adopt the single core power cable or a plurality of grounding wire arranged symmetrical cable. Small power and suitable for wiring, priority is to use multi-core shielded cable." As the PE line symmetrical configuration of the 3+3 inverter dedicated cable, construction is always raised, not wiring, we later too lazy to explain, usually directly with the 3+1 type multi-core shielded cable. From the running situation, the effect is also good.

- Q: How does frequency converter realize variable frequency speed regulation?

- The frequency of the electric field is changed, and the frequency of the original fixed 50 Hz is reduced as required, and then the rotation frequency of the induction motor is changed

- Q: Today, I was asked the question, and I also brought it to you to share the following Oh!

- The frequency of the electricity we use everyday is 50Hz. If we want to change the frequency, we have to change it through the frequency converter.The working principle of frequency converter is to change the frequency alternating current into no frequency direct current, and then control it by electronic circuit so that it can adjust its frequency alternating current at any time.The inverter is similar to the back half of the inverter, which converts the direct current into alternating current.

- Q: How do you understand the ramp up (descent) time of the inverter? Thank you!

- That is, the frequency converter starts from the time it takes to set the upper limit. It can be said to be the acceleration time, which can be set in the parameters of the converter. Then, the deceleration time is just the opposite.

- Q: What does "EPCU" mean in a frequency converter?

- But look at your inverter has also been used for some time, if not before, and now appear, it is estimated that the hardware is broken, and manufacturers communicate maintenance!

- Q: How much is the motor 90KW and the frequency converter selected?Colleagues suggest 110W?The cost will be higherIs it okay to choose 90KW?

- Motor 90KW, frequency converter, 90KW can be applied, but the frequency can not exceed the rated value of the motor. There are some occasions to live and use the frequency converter to speed up the motor, so it should be chosen a little larger, otherwise the inverter will be more loaded.

- Q: What does the RUN key on the inverter mean? How do you use it?

- When selecting panel operations (when the panel of the inverter is the control source of the inverter), it is the meaning of the "running" button.Frequency converter (Variable-frequency, Drive, VFD) is the application of frequency conversion technology and microelectronics technology, by changing the power supply frequency of the motor to control AC motor power control equipment. The frequency converter is mainly composed of rectifier (AC DC converter), filter, inverter (DC AC converter), brake unit, drive unit, detection unit, micro processing unit and so on. The inverter adjusts the voltage and frequency of the output power by disconnecting the internal IGBT

- Q: What are the benefits of installing economizer in industrial enterprises?

- The input and output filter and the DC reactor in the economizer can prevent the harmonic produced by the converter and cause the pollution of the power grid and the surrounding electricity environment.3 、 no disturbance power supply / electricity saving conversion system is beneficial to ensure that the customer load can be put into use quickly when the machine fails, and the normal production of the customer will not be affected. At the same time, the protection function of the economizer is perfect, and it has the protection function of over voltage, under voltage, over current, over temperature and surge resistance.4, reactive power compensation, improve the power factor of the system, reduce reactive power loss.

- Q: What do you mean by the capacity of the inverter and the capacity of the motor?

- Because the motor consumes active power and consumes reactive power, and the reactive power is also occupied, the motor with 70KW can only be usedThe power is known to everyone

Send your message to us

AC Driver China Best Selling VFD Frequency Drive 3 phase 380V 11kw

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords