7000 Series Aluminum Alloy Sheet Best Quality in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of 7000 Series Aluminum Alloy Sheet

Aluminum Coil/Sheet | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

2. Application of 7000 Series Aluminum Alloy Sheet

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of 7000 Series Aluminum Alloy Sheet

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

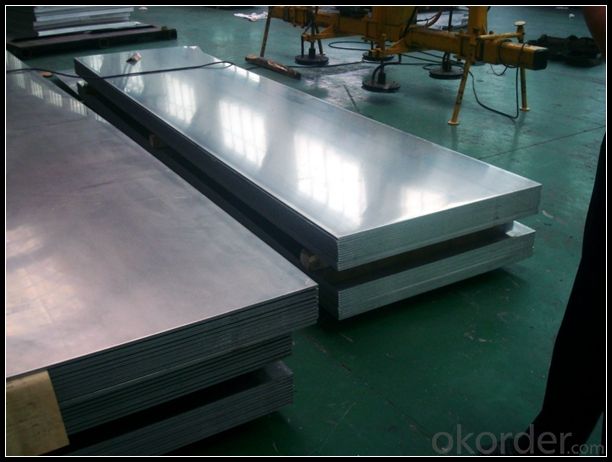

5. Image of 7000 Series Aluminum Alloy Sheet

6. Package and shipping of 7000 Series Aluminum Alloy Sheet

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:Is aluminum sheet recyclable?

- Indeed, aluminum sheet possesses a high recyclability factor. In fact, it ranks among the most sustainable and environmentally conscious materials available. This is due to its unique ability to be recycled endlessly without any compromise to its quality. The process of recycling aluminum sheet involves melting it down until it reaches a liquid state. Interestingly, this process requires far less energy than producing primary aluminum from raw materials. By engaging in the recycling of aluminum sheet, we not only preserve our precious natural resources but also play a crucial role in reducing greenhouse gas emissions and conserving energy. It has been estimated that recycling just one ton of aluminum sheet can save up to nine tons of CO2 emissions. Therefore, embracing the practice of aluminum sheet recycling is not only economically feasible but also a vital step in fostering a sustainable and eco-friendly environment.

- Q:What is the usage of aluminum sulfate for every ton of paper produce for kraft paper and news print

- Aluminium sulphate was the most extensively used chemical raw material in the papermaking industry. Its primary use was in the rosin sizing of paper where the rosin soap was reacted with aluminium sulphate to impart hydrophobis characteristics to the paper. The alum had a side benefit in fixing all types of anionic substances into the paper web. All types of paper, even those that were not sized, such as newsprint,were made using alum. This resulted in the paper being made under acidic conditions. The technology has changed markedly over the last 10 to 20 years with synthetic sizing agents being developed which do not require reaction with alum. In my country there is not 1kg of fine writing and printing paper made with rosin/ alum sizing, and no alum is used at all. Various synthetic highly charged cationic resins have been developed, such as polyacrylamide resins, polyethyleneimine resins, etc, whic are used as fixing and retention agents, so that alum has been virtually eliminated. To sum up the importance of aluminium sulphate as a papermaking chemical is now very limited.

- Q:how many aluminum ions are present?how many chloride ions are present?what is the mass in grams of one molecule of aluminum chloride?help! i have no clue how to do this i need to know how for my quiz!!!

- You have to remember Avogadro's number: 6.02 x 10^23 Read about it in your text book. It is the number of molecules of any atom that make up 1 mole. 1 mole of a molecule is equal to it's atomic weight in grams. So, the atomic weight of aluminum is 26.9. So, 26.9 grams of aluminum contains exactly 6.02 x 10^23 molecules of aluminum (or 1 mole). What's the molecular weight of aluminum chloride? Well, 26.9 + 3(35.5) = 133.4 the 35.5 is the molecular weight of chloride and there are 3 of them. So, 133.4 grams of aluminum chloride would be 6.02 x 10^23 molecules. We only have 37.2 g. 37.2 g/ 133.4 g per mole = 0.279 moles. 0.279 moles x (6.02 x 10^23 molecules/mole) = 1.68 x 10^23 molecules of aluminum chloride. So, since there is one aluminum per molecule, you have your answer. Just multiply by three to find out how many molecules of chloride are present. Finally, if 133.4g = 6.02 x 10^23 molecules, then 1 molecule = 133.4 / 6.02x10^23 = 22.16 x 10^-23 or 2.216 x 10^-22 Make sure that the periodic table you use for class has the same values (some tables are more simplified then others). Also, make sure that you use the correct number of scientific digits when calculating your answer.

- Q:Are the aluminum sheets suitable for manufacturing architectural column covers?

- Yes, architectural column covers can be manufactured using aluminum sheets. Aluminum is a material that is both lightweight and durable, offering excellent resistance to corrosion. This makes it an ideal choice for exterior applications like column covers. It is also easily shaped, bent, and fabricated, allowing for the creation of customized designs and sizes. This versatility is beneficial for architectural projects. Furthermore, aluminum sheets can be finished with various coatings, such as powder coating or anodizing, to enhance their visual appeal and provide extra protection against weathering and wear. Overall, aluminum sheets are a suitable option for manufacturing architectural column covers due to their combination of strength, versatility, and aesthetics.

- Q:Are the aluminum sheets suitable for manufacturing solar reflectors?

- Aluminum sheets, indeed, prove to be fitting for the production of solar reflectors. As a material, aluminum possesses high reflectivity, enabling it to efficiently bounce off sunlight, thereby making it an optimal selection for solar reflectors. Its remarkable reflectivity and minimal heat absorption, owing to its low emissivity, allow it to effectively deflect a substantial amount of solar radiation. Moreover, aluminum exhibits qualities of being lightweight, long-lasting, and resistant to corrosion, rendering it appropriate for outdoor usage. Furthermore, its malleability permits simple shaping and molding into diverse reflector designs. All in all, aluminum sheets offer exceptional performance and dependability when it comes to constructing solar reflectors in solar energy systems.

- Q:Are aluminum sheets suitable for signage and advertising?

- Yes, aluminum sheets are suitable for signage and advertising. They are durable, weather-resistant, and can be easily customized with graphics and text. Additionally, their sleek and professional appearance makes them an excellent choice for promotional materials, outdoor signs, and indoor displays.

- Q:Can aluminum sheets be used for chemical reactors?

- Yes, aluminum sheets can be used for chemical reactors. Aluminum is often chosen for its corrosion resistance, lightweight properties, and ability to withstand high temperatures, making it suitable for various chemical processes in reactor applications. However, it is important to consider the specific chemical reactions and conditions involved, as certain chemicals or extreme conditions may chemically react with or degrade aluminum.

- Q:What are the different bending methods for aluminum sheets?

- There are several different bending methods for aluminum sheets, each with its own advantages and limitations. Some of the commonly used bending methods for aluminum sheets include: 1. Air Bending: This method involves using a punch and die to create a bend in the aluminum sheet without directly touching it. Compressed air is used to apply force on the sheet, resulting in the desired bend. Air bending is a versatile method that allows for a variety of bend angles and radii. 2. Bottom Bending: In this method, the aluminum sheet is clamped between a V-shaped die and a flat die. A punch is then used to press the sheet into the V-shaped die, creating the desired bend. Bottom bending is suitable for creating sharp bends with small radii. 3. Coining: Coined bends are created by applying high pressure to the aluminum sheet between a punch and a die. This method produces precise, crisp bends with minimal springback. However, it requires specialized equipment and is typically used for high-volume production. 4. Roll Bending: Roll bending involves passing the aluminum sheet between a set of rollers to gradually bend it into the desired shape. This method is commonly used for creating cylindrical or conical shapes. Roll bending can achieve large radii and is suitable for thicker aluminum sheets. 5. Press Brake Bending: Press brake bending is a common method that uses a hydraulic or mechanical press brake to create bends in aluminum sheets. The sheet is clamped between a punch and a die, and the press brake applies force to create the bend. Press brake bending offers flexibility in terms of bend angles and radii. It is important to note that the choice of bending method depends on various factors such as the desired bend angle, radius, material thickness, and the specific requirements of the application.

- Q:Are the aluminum sheets suitable for manufacturing heat exchangers?

- Indeed, aluminum sheets prove to be fitting for the production of heat exchangers. Aluminum, being both lightweight and highly conductive, serves as an ideal option for heat transfer purposes. Its exceptional thermal conductivity facilitates efficient heat transfer, resulting in effective cooling or heating procedures. Moreover, aluminum's resistance to corrosion is of utmost importance for heat exchangers that encounter diverse fluids. Furthermore, the malleability and formability of aluminum sheets render them effortlessly malleable into the required designs for heat exchanger components. On the whole, aluminum sheets offer numerous benefits for the manufacturing of heat exchangers, thus making them a suitable selection for this particular application.

- Q:Can 101 aluminum sheets be recycled?

- Certainly, it is possible to recycle 101 aluminum sheets. Aluminum possesses a remarkable recyclability, boasting an impressively efficient recycling procedure. Through the act of recycling aluminum sheets, we not only preserve valuable resources but also conserve energy and diminish greenhouse gas emissions. Additionally, recycling aluminum aids in the reduction of landfill waste and curtails the necessity for fresh aluminum ore mining. Consequently, we highly recommend recycling 101 aluminum sheets to actively contribute towards a future that is more sustainable and environmentally conscious.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

7000 Series Aluminum Alloy Sheet Best Quality in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords