400mm Graphite Electrode for RP Grade for Foundry Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Graphite Electrode Description

We has complete production lines, which include raw material mixing, forming line, baking line, impregnation equipment, graphitization line and machining and shaping line. Our annual capacity is 60,0000tons.

2.Main Features of the Graphite Electrode

(1) Direct manufacturer, office based on Beijing.

(2) Competitive price with prior quality

(3) High density with low resistivity

(4) High carbon content

(5) RP HD HP UHP Grade for your reference

3.Graphite Electrode Images

Packaging: Wooden Pallets, well packaged.

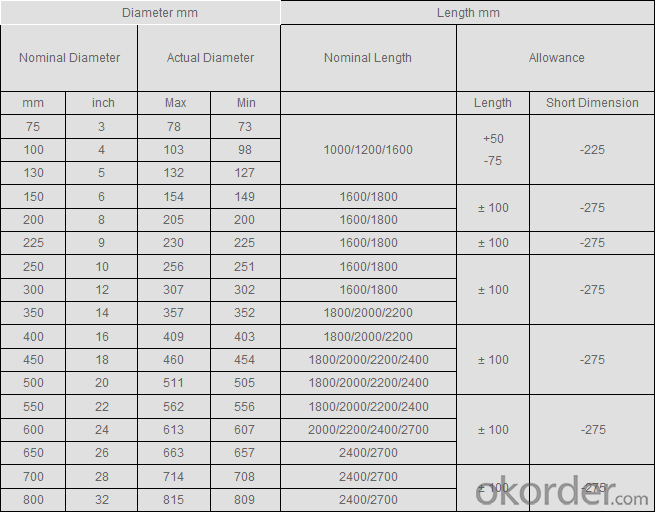

4.Graphite Electrode Specification

5.FAQ

(1) How to guarantee the quality of the products?

We have established the international advanced quality management system, every link from raw material to final product we have strict quality test; we resolutely put an end to unqualified products material flowing into the market. At the same time, we will provide necessary follow-up service assurance. We welcome you to visit our mill.

(2) MOQ

For trial order, we accept 20 MT.

(3) Payment term

30% deposit, balance against the BL copy; 100% L/C at sight.

(4) How long can we receive the product after purchase?

We have large quantity in stock, and we could machine it to the size you need, so the delivery time is around 25 days after receiving your deposit or L/C.

- Q: Use of graphite in steelmaking

- At present in the world (MgO-C brick raw material for graphite and magnesium) as refractory material, has been widely used in steelmaking, has become a traditional use of graphite.

- Q: What are the skills of hardfacing process for wear-resistant alloy powder blocks?

- The power supply adopts the DC arc welding machine with steep drop characteristic, adopts the positive connection method, the electrode is negative, and the electrode is a high strength spectrum pure graphite rod,

- Q: What is the graphite furnace electrode with a diameter of 400?

- The variety and specifications of graphite electrodes used in modern EAF steelmaking are mainly determined by the technical parameters of the steelmaking furnace.

- Q: The difference between graphite electrode and graphite rod

- The difference between an electrode and a rod is that the electrode has a lead conductor, and the rod is not.

- Q: Please senior doubts. The graphite electrode is used in the mold cavity In what case is graphite processing taken?

- Instead of copper as discharge material.1. Electrode design1 can reduce the number of individual electrodes / can be made into a composite electrode2, it can save the electrode clamp system and save the cost2, the electrode processing1, high speed milling rough processing copper block 3 times2, high-speed milling finishing faster than copper 5 times3. Good machinability4, complex geometric modeling can be realized3, light weight, its density is less than 1/4 of copper1, good thermal stability (without deformation)2 can reduce the number of individual electrodes / can be made into a composite electrode3, without deburring4. The electrode is easy to clamp4 、 electric discharge machining EDM1, roughing, the electrode loss is small2, high work removal rate3 can reduce the number of individual electrodes / can be made into a composite electrode4. No pollution to the environment in the electrolyte5, light weight, its density is less than 1/4 of copper6, excellent thermal stability, the electrode does not change7, the fine graphite electrode can be used to produce high quality workpiece surfaceDifferent grades of graphite materials can be used for processing different workpieces

- Q: What's the purpose of the electrode material?When the electrolytic molten state of NaCl is said, what is the use of the graphite electrode and the iron electrode?

- 1. graphite (two kinds of EDM3 and EDM200)2. copperIn general, graphite electrode for extensive escape material (graphite texture loose, discharge energy is relatively large, removal of materials faster, but face flowers that roughness is relatively large

- Q: Why is the production of one ton of ultra high power graphite electrode requires 1.05 tons of coke?

- After calcined to eliminate ash and volatile part of the points in this process will be a lot of weight loss, in the process of crushing mixing in process of baking or graphite in high temperature heat treatment, another part of the impurities were excluded, so the raw material is higher than the rate of finished products.

- Q: Why is graphite a negative pole and copper is an anode?

- The process of causing a chemical change by passing through a substance. Chemical change is the process in which material is lost or obtained by electrolysis (oxidation or reduction). Electrolysis is performed in an electrolytic cell. The electrolytic cell is composed of two electrodes, yin and Yang, which are respectively immersed in the solution containing positive and negative ions. The current into the negative electrode (cathode), are positively charged ions migrate to the cathode solution, and with the combination of electronic elements, become neutral or negatively charged molecules; negative ion transfer to another electrode (anode), electrons are given into neutral elements or molecules.

- Q: What about graphite electrodes for steel mills?

- For steel and iron alloys, graphite electrodes are used, when powerful currents pass through electrodes into the melting zone of the electric furnace to produce an arcThe electric energy is converted into heat energy, and the temperature is increased to about 2000 degrees, so as to achieve the purpose of smelting or reaction. In addition, the electrolytic goldWhen the magnesium, aluminium and sodium are used, the anode of the electrolytic cell is also made of graphite electrode. The resistance furnace for carborundum is also made of graphite electrode as the burnerConductive material.

- Q: I remember the more lively metal, the electron?

- C is a salt solution of copper metal because copper is first reduced to a single element on a graphite electrode.Moreover, the addition of dilute sulfuric acid has a H2 emission, then a H of the previous metal.

Send your message to us

400mm Graphite Electrode for RP Grade for Foundry Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches