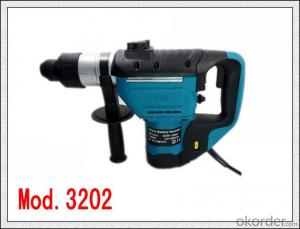

32mm Rotary Hammer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 500Pcs pc

- Supply Capability:

- 10000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

32mm Rotary Hammer

* CN3323

* Rated Voltage: 110-240V~50-60Hz

* Rated Input Power:1100W

* No-Load Speed: 0-800rpm

* Impact Rate: 3200rpm

* Drilling Capacity: 32mm

* 3 Function: Rotation/Rotation&Hammer/Hammer

* Standard Accessories:

3 Sds-Plus Drill Bits 8/10/12x150mm, 2 Chisel Bits 14x250 Mm (Flat&Point), 1 Wrench

* Packing: 45*28*36cm/2pcs, 16/18kgs, 1200pcs/20'cy

* W/CE, GS, EMC, PAHS

Features of 32mm Rotary Hammer

1.Use of magnesium alloy greatly lightens the weight of the tool, which improves working efficiency;

2.Crafty SDS plus chuck bit system enables rotary hammers of relatively lower power to work more efficiently;

3.Through continuous improvements to inner transmitting chain of mechanism, the overall performance is enhanced to ha higher level.

4.Double Anti-Vibration System,Hengyou's Patent, greatly alleviates counterforce to users by the tool. It dramatically relieves fatigue of users, which helps to improve working efficiency;

5.Heat Elimination System,Hengyou's up-to-date design, can dissipate heat through working of the fan. HES largely lowers rotary hammer's temperature, which helps to extend life time of the tool;

6.Patented tool-free grease cover could help users to add grease,even if no wrench is available at hand, which also helps to improve working efficiency;

7.Design of variable speed provides users with more choices when working under different environments;

8.Auto-stop carbon brush with high quality greatly extends life time of the motor part, which not only saves maintenance cost, but also create more values for users;

9.Main handle and auxiliary handle have been covered by soft grip makes users feel more confortable when working;

10.Brand new designed function switch would help you to shift functions more quickly labor-saving.

- Q: How are hand powered tools classified into class I, class II, class III?

- Simple methods are: hand-held electric tools for metal shell for class I. The plastic case is of the type ii. Class III uses safe voltage.

- Q: Which is good between pneumatic tools and power tools?

- The utility model relates to an electric tool, which is a hand-held or movable mechanical tool, which is driven by an electric motor or an electromagnet, and is driven by a transmission mechanism to operate the working head. Electric tool has the characteristics of portability, simple operation, multiple functions, can greatly reduce labor intensity, improve work efficiency, realize the mechanization of manual operation, which is widely used in building, housing decoration, automobile, machinery, electric power, bridges, gardening and other fields, and poured into the family.

- Q: How about plug wires and cables for power tools?

- Class I tools are common type power tools with a rated voltage of over 50 volts. Class I tools not only rely on basic insulation but also include an additional safety measure in the protection against electric shock. The method is that the accessible conductive parts and protection has been installed in the fixed line in the (ground) wire together, make accessible conductive parts in the basic insulation does not become damaged in the charged body. Plug for three pin plug type tool.

- Q: What's the role of carbon brushes in electric tools?

- Carbon brush specific function1. the external current (excitation current) is added to the rotor by carbon brush (input current);2., the static charge on the big shaft is introduced into the earth (carbon brush) through the carbon brush (output current);3. lead the main shaft (ground) to the protection device for rotor ground protection and measure the positive and negative voltage of the rotor;

- Q: What's the name of an electric tool for riveting screws into wood? Not understand!

- If the factory is assembled, use an electric screwdriver! Only suitable for twisting small screws! Because the torque itself is not large! Like you twist it on a wood, use a Zigong drill, or a rechargeable drill! Because of these two belts with adjustable torque! Unlike an electric drill, it always turns that way! This torque is automatically separated by reaching a certain torque! If you screw a big screw, it's an electric wrench!

- Q: How are the I, II, and III classes of power tools classified?

- The popular point is that:The 1 type of tool is metal housing with ground wire.The 2 type of tool is the insulated housing.The 3 type is low voltageOfficial point of explanation can be searched for power tool category ~!

- Q: Compared to pneumatic tools, what are the advantages of electric tools?

- The pneumatic tool is more environment-friendly, energy-saving, and has better environmental adaptability, and is safer than an electric tool. The pneumatic tool has the advantages of simple structure, convenient operation, long service life and convenient maintenance

- Q: What is the working principle of power tools?

- AC motor, AC motor of induction motor, its strong induction current (eddy current) magnetic field generated in the rotation of the magnetic force on the rotor copper bar, continuous cutting, according to Lenz's law, the induced current has the effect of relative motion occurs against the rotor magnetic field and the rotor is, with the magnetic field and rotation. But the rotor rotation speed of the high speed magnetic field does not transform, otherwise it will not be able to cut the copper lines.

- Q: What devices must be available for all hand held electric tools?

- Anti leakage, splash prevention, anti movement, anti overheating

- Q: Is there an electric tool for screwing bolts? It's bolts, not screws

- Yes, I use it every day. The electric wrench is specially used to tighten the bolts. It has a sleeve with a bolt size at the front, and different sleeves can be changed to screw the bolts of different sizes. It's very convenient and quick to use.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 1998 |

| Annual Output Value | US$ 30 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Mid East Eastern Asia Western Europe Northern Europe Southern Europe South Asia |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai; Ningbo |

| Export Percentage | 71% - 80% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | About 10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average; Low |

Send your message to us

32mm Rotary Hammer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 500Pcs pc

- Supply Capability:

- 10000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches