316 Hard Stainless Steel Sheet Mirror Finish Hot Rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Mirror Finish Hot Rolled 316 Hard Stainless Steel Sheet

Name | Mirror Finish Hot Rolled 316 Hard Stainless Steel Sheet |

Grade | 304/316L/321/310S/2205 |

Thickness | 0.3mm-20.00mm |

Width | 1000mm-2000mm |

Length | 6m or as customers' request |

Tolerance | Thickness: ±0.02mm Length: ± 5mm |

Brand | BAOSTEEL,TISCO,ZPSS |

Standard | ISO,ASTM,SUS,GB etc |

Surface | 2B,BA,6K,8K,12K,No1,Polished, |

Place of origin | Wuxi China (mainland) |

Application | Decoration Industry Kitchenwave Building Elevator Upholstery

|

Packing | Standard export seaworthy package or as customer |

Payment terms | 1.30%T/T in advance ,the balance against the B/L copy 2.30%T/T in advance,the balance be paid by L/C at sight |

Surface--stainless steel sheet

Surface | Definition | Application | Photo |

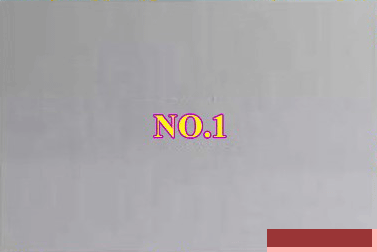

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |  |

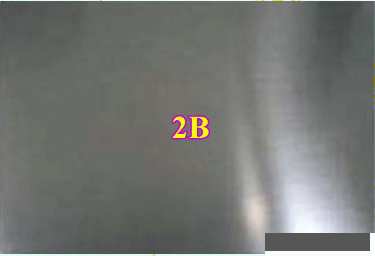

| 2B | Those finished, after cold rolling, by heat treatment,pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry,Construction material, Kitchen utensils. |  |

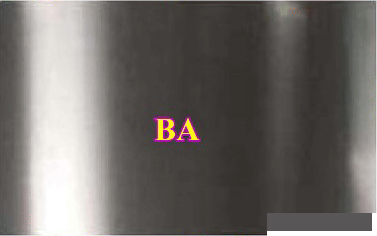

| BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils. Electric equipment,Building construction. |  |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction,Medical equipment. |  |

| HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size | Building Construction. |  |

Chemical Composition(%) of Stainless Steel Sheet

No. | Grade | Chemical Composition % | ||||||||||

C | Cr | Ni | Mn | P | S | Mo | Si | Cu | N | Other | ||

201 | 1Cr17Mn6Ni5N | ≤0.15 | 16.00-18.00 | 3.50-5.50 | 5.50-7.50 | ≤0.060 | ≤0.030 | - | ≤1.00 | - | ≤0.25 | - |

202 | 1Cr18Mn8Ni5N | ≤0.15 | 17.00-19.00 | 4.00-6.00 | 7.50-10.00 | ≤0.060 | ≤0.030 | ≤1.00 | - | ≤0.25 | - | |

301 | 1Cr17Ni7 | ≤0.15 | 16.00-18.00 | 6.00-8.00 | ≤2.00 | ≤0.065 | ≤0.030 | - | ≤1.00 | - | - | - |

304 | 0Cr18Ni9 | ≤0.07 | 17.00-19.00 | 8.00-10.00 | ≤2.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | - | - | - |

304L | 00Cr19Ni10 | ≤0.030 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | - | - | - |

310S | 0Cr25Ni20 | ≤0.08 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | - | - | - |

316 | 0Cr17Ni12Mo2 | ≤0.08 | 16.00-18.50 | 10.00-14.00 | ≤2.00 | ≤0.035 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - | - |

0Cr18Ni12Mo2Ti | ≤0.08 | 16.00-19.00 | 11.00-14.00 | ≤2.00 | ≤0.035 | ≤0.030 | 1.80-2.50 | ≤1.00 | - | - | Ti5*C%-0.70 | |

316L | 00Cr17Ni14Mo2 | ≤0.030 | 16.00-18.00 | 12.00-15.00 | ≤2.00 | ≤0.035 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - | - |

Production Show

Applications

Be extensively applied to architectural decoration, such as elevator decoration, luxurious doors, outdoor projects, wall decoration, advertisement nameplates, sanitary ware, ceiling, corridor, hotel hall, shop facade.Kitchenware, food industry, electronic industry, medical equipment, etc.

Chemical Compositon and Physical Property:

| Type | Chemical Composition (%) | |||||

| 410 | C | SI | Mn | S | P | Cr |

| 0.03 | 0.32 | 0.25 | 0.001 | 0.019 | 12.21 | |

- Q: What does "80 wire" stainless steel plate mean? How much more expensive than the average stainless steel plate?

- It's 0.08mm stainless steel!! It's so thin. It's expensive. A kilo is at least 10 yuan!!

- Q: Are stainless steel sheets suitable for wastewater treatment plants?

- Yes, stainless steel sheets are highly suitable for wastewater treatment plants. Stainless steel is known for its corrosion resistance, durability, and ability to withstand harsh and corrosive environments, making it an ideal material for such applications. It can effectively handle the challenges posed by wastewater treatment plants, including exposure to chemicals, moisture, and high temperatures, while maintaining its structural integrity and preventing contamination.

- Q: Are stainless steel sheets suitable for outdoor signage?

- Yes, stainless steel sheets are highly suitable for outdoor signage. They are durable, weather-resistant, and able to withstand harsh outdoor conditions such as rain, sun exposure, and extreme temperatures. Stainless steel sheets also offer a sleek and modern aesthetic, making them an ideal choice for outdoor signage that needs to be both functional and visually appealing.

- Q: What specifications do stainless steel plates have?

- This is not specified. Do you want to make 201 or 304?. You can measure the size of the bag you want. Double fold (usually 10MM), such as length, width, and thickness of the package. Go and ask someone to do it for you. If fitted, use a glass or spot weld.

- Q: Are stainless steel sheets suitable for architectural mesh or screens?

- Yes, stainless steel sheets are highly suitable for architectural mesh or screens. They possess excellent durability, corrosion resistance, and aesthetic appeal, making them ideal for various architectural applications. Additionally, stainless steel sheets offer flexibility in design, allowing for intricate patterns and shapes in architectural mesh or screens.

- Q: Can stainless steel sheets be used for decorative screens?

- Yes, stainless steel sheets can be used for decorative screens. Stainless steel is a versatile material that is often used for its aesthetic appeal and durability. It can be easily shaped and formed into various designs, making it suitable for creating decorative screens. Additionally, stainless steel is resistant to corrosion and can withstand harsh weather conditions, making it ideal for both indoor and outdoor applications. With its sleek and modern appearance, stainless steel sheets can add a touch of elegance and sophistication to any space, making them a popular choice for decorative screens in residential and commercial settings.

- Q: What are the common uses of stainless steel sheets?

- Stainless steel sheets possess distinctive properties and versatility, enabling them to be widely utilized in a myriad of applications. Some of the most prevalent uses are as follows: 1. Within the construction industry, stainless steel sheets are extensively employed for roofing, cladding, and facades. The combination of their exceptional durability, resistance to corrosion, and contemporary aesthetic appeal renders them highly desirable. 2. The automotive sector also benefits from the utilization of stainless steel sheets, particularly in the production of components such as exhaust systems, grilles, trims, and decorative elements. Their capacity to withstand heat, corrosion, and impact makes them an ideal choice for these purposes. 3. In the manufacturing of kitchen appliances like refrigerators, ovens, dishwashers, and sinks, stainless steel sheets are commonly employed. Their hygienic properties, stain resistance, and ease of maintenance contribute to their popularity in these applications. 4. The food processing industry extensively relies on stainless steel sheets due to their non-reactive nature and ease of cleaning. They are employed in the fabrication of equipment such as storage tanks, conveyor systems, work surfaces, and food preparation tables. 5. The manufacturing of medical equipment and devices heavily relies on stainless steel sheets. They are instrumental in the production of surgical instruments, dental tools, implantable devices, and hospital furniture owing to their biocompatible nature, corrosion resistance, and ease of sterilization. 6. In the aerospace industry, stainless steel sheets find application in the construction of aircraft components such as fuselage frames, engine parts, and landing gear. Their exceptional strength-to-weight ratio, resistance to extreme temperatures, and corrosion resistance render them suitable for these demanding applications. 7. Within the energy and power generation sectors, stainless steel sheets are commonly employed in power plants, oil refineries, and chemical processing plants for the construction of equipment like heat exchangers, boilers, and storage tanks. Their ability to withstand high temperatures, pressure, and corrosive environments is indispensable in these industries. 8. Stainless steel sheets also serve decorative purposes in architecture and interior design. They can be utilized to create unique and modern finishes on walls, ceilings, furniture, and decorative panels. In conclusion, stainless steel sheets are a versatile material that finds application in various industries due to their exceptional properties, including corrosion resistance, durability, hygienic properties, and aesthetic appeal.

- Q: Are stainless steel sheets suitable for marine propellers?

- Yes, stainless steel sheets are suitable for marine propellers. Stainless steel is a popular material choice for marine propellers due to its excellent corrosion resistance properties, which is essential in a marine environment where the propeller is constantly exposed to saltwater. The high strength and durability of stainless steel sheets also make them capable of withstanding the harsh conditions of the marine environment, including impacts and vibrations. Additionally, stainless steel has a low magnetic permeability, which helps reduce the formation of biofouling on the propeller, improving its performance and efficiency. Overall, stainless steel sheets are a suitable and widely used material for marine propellers.

- Q: What are the different types of colored finishes available for stainless steel sheets?

- There are several different types of colored finishes available for stainless steel sheets. These finishes are designed to enhance the appearance of stainless steel and provide various aesthetic options. Some of the most common colored finishes include: 1. Mirror Finish: This finish is highly reflective and creates a mirror-like surface on stainless steel sheets. It is achieved by polishing the stainless steel surface to a high gloss. Mirror finishes are commonly used in decorative applications and provide a sleek and modern look. 2. Satin Finish: Also known as brushed or matte finish, this type of finish has a smooth, non-reflective surface. It is achieved by brushing the stainless steel surface with an abrasive material. Satin finishes are commonly used in architectural and industrial applications and provide a clean and contemporary appearance. 3. Colored Powder Coating: Powder coating involves applying a dry powder to the stainless steel surface and then curing it under heat. This process creates a durable and uniform colored finish. Colored powder coatings are available in a wide range of hues, allowing for customization and versatility in design. 4. PVD Coating: Physical Vapor Deposition (PVD) is a process that involves depositing a thin layer of metal onto the stainless steel surface. This coating can be in various colors, such as gold, bronze, black, or rose gold. PVD coatings provide excellent durability and resistance to wear, making them suitable for high-traffic areas or decorative applications. 5. Colored Anodizing: Anodizing is an electrochemical process that creates a protective oxide layer on the stainless steel surface. By using dyes during the anodizing process, a wide range of colors can be achieved. Colored anodized finishes are known for their corrosion resistance and can be utilized in architectural or design-oriented applications. Each of these colored finishes offers unique characteristics and can be chosen based on the desired aesthetic, durability, and specific application requirements. It is important to consider factors such as the level of maintenance needed, environmental conditions, and the intended use of the stainless steel sheets when selecting a colored finish.

- Q: How do you determine the hardness of stainless steel sheets?

- There are multiple methods available to determine the hardness of stainless steel sheets. The Rockwell hardness test is a commonly used method that involves measuring the depth of indentation on the material's surface. This is done by applying a specific load using a diamond cone or steel ball and measuring the resulting depth of penetration. The Rockwell hardness value is then determined based on this depth. Another method is the Vickers hardness test, which involves using a diamond indenter to create a square-shaped indentation. The size of this indentation is measured and converted into a hardness value. This method is often preferred for thin materials like stainless steel sheets. The Brinell hardness test is an alternative technique where a known load is applied to the material using a hardened steel ball. The resulting indentation's diameter is then measured, and the hardness value is calculated based on both the applied load and the diameter of the indentation. Apart from these mechanical tests, non-destructive methods such as ultrasonic hardness testing and magnetic hardness testing can also be employed. Ultrasonic testing determines the speed of sound through the material, which is then correlated to its hardness. Magnetic hardness testing, on the other hand, measures the magnetic properties of the material, which are affected by its hardness. Overall, the hardness of stainless steel sheets can be determined using various methods depending on the specific requirements and characteristics of the material.

Send your message to us

316 Hard Stainless Steel Sheet Mirror Finish Hot Rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords