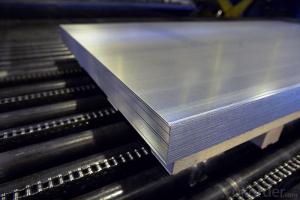

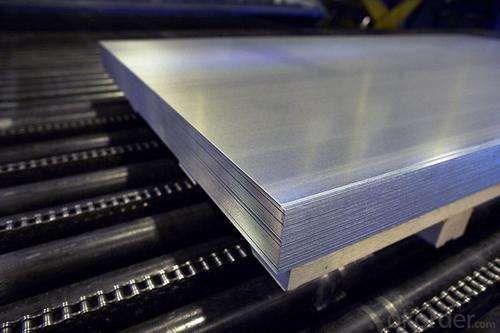

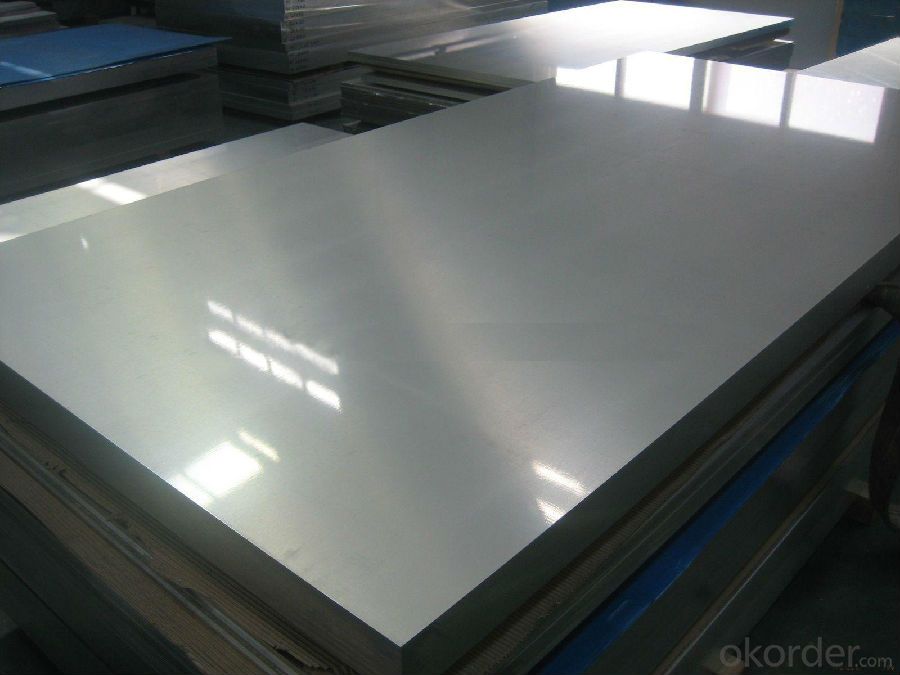

304 Stainless Steel Sheet 304 Stainless Steel Plate 06Cr18Ni9

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

304 Stainless Steel Sheet 304 Stainless Steel Plate 06Cr18Ni9

Packaging Details:Wooden pallets,water proof paper-20'GP or 40'GP for stainless steel sheet.

Delivery Detail:within 5-7 days after receiving the deposit

1. Specifications about stainless steel sheet

Commodity | Professional 430 201 202 304 304l 316 316l 321 310s 309s 904l stainless steel sheet |

Grade | 201,202,304,304L,316,316L,310S,309S,321,301,310,410,420,430,904L |

Brand | TISCO ,BAOSTEEL,POSCO,JISCO,LISCO |

Certification | SGS,BV,IQI,TUV,ISO,etc |

Thickness | 0.2mm-150mm |

Width | 1000,1219,1250,1500mm, or as your requirements |

Length | 2000,2438,2500,3000,6000mm, or as your requirements |

Surface | No.1, 2B, BA, 8K Mirror, Hairline,satin, Embossed,brush,No.4,HL,matt,pvc film,laser film. |

Standard | ASTM,AISI,SUS,JIS,EN,DIN,GB, ASME,etc |

Delivery time | 5-7 days after confirming the order |

MOQ | 1 Ton |

Advantages | Showing the splendor of your quality, wearresistant as well , strong corrosion resistance and decorative effect, durable and beautiful in good taste. |

2.Production Flow about stainless steel sheet

Raw materials are sending to hot rolling units for rolling into different sizes

Hot rolled material is annealing in cold; rolled annealing furnace and pickling in acid.

All mill rolls are grinded on precision grinding machine with proper chamfering after first shiftoperation.

All sheets are pickled in different tanks and dried on brush roll machine before dispatched.

These sheets are again annealing and are sent to straighten machine for straightening.

Inspections are done at various stages. Keep proper control overall internal process via rolling,annealin and pickling by our experienced staff.

3.Surface--stainless steel sheet

| Surface Finish | Definition | Application |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA/8K mirror | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

| Hairline | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

- Q: What is the thickness range of stainless steel sheets?

- The thickness range of stainless steel sheets can vary depending on the specific grade and application. However, typically stainless steel sheets are available in thicknesses ranging from 0.4mm to 6mm. Additionally, there are specialized stainless steel sheets available in thinner gauges, such as foil sheets that can be as thin as 0.02mm. On the other hand, for heavy-duty applications, stainless steel sheets can be as thick as 50mm or more. Ultimately, the desired thickness of a stainless steel sheet will depend on the intended use, structural requirements, and aesthetic preferences.

- Q: Can stainless steel sheets be used for solar panel frames?

- Yes, stainless steel sheets can be used for solar panel frames. Stainless steel is known for its durability, corrosion resistance, and high strength-to-weight ratio, making it an ideal material choice for constructing solar panel frames that need to withstand various weather conditions and support the weight of the panels.

- Q: Are stainless steel sheets resistant to crevice corrosion?

- Stainless steel sheets generally possess resistance to crevice corrosion, which occurs in confined spaces like gaps or crevices between surfaces, where limited oxygen and other corrosive agents exist. These sheets are primarily composed of iron, chromium, and other alloying elements that generate a protective oxide layer on their surface, effectively preventing the infiltration of corrosive agents. This oxide layer acts as a barrier, endowing stainless steel with high resistance against crevice corrosion. However, it's worth noting that the degree of resistance can vary based on the specific grade and composition of the stainless steel, as well as the environmental conditions it encounters.

- Q: What are the properties of stainless steel sheets?

- Stainless steel sheets possess multiple properties that make them extremely desirable in various industries and applications. To begin with, their excellent corrosion resistance is a result of the presence of chromium in the alloy, which forms a protective oxide layer on the surface, preventing rust and staining. Moreover, stainless steel sheets are renowned for their strength and durability. They can withstand heavy loads and resist deformation due to their high tensile strength. This makes them suitable for applications requiring structural integrity and longevity, such as in construction, automotive, and aerospace sectors. Another significant property of stainless steel sheets is their resistance to heat and fire. They can endure high temperatures without losing their structural integrity or strength. As a result, they are ideal for applications involving extreme heat, like commercial kitchens and industrial furnaces. Additionally, stainless steel sheets are hygienic and easy to clean, making them suitable for use in the food and medical industries. Their non-porous surface prevents the growth of bacteria, making them a reliable choice for food processing equipment, surgical instruments, and medical devices. They also possess an attractive appearance, with a smooth, reflective surface that is easy to maintain. This makes them aesthetically pleasing and suitable for architectural and decorative applications, such as building facades, interior design, and furniture manufacturing. Lastly, stainless steel sheets are highly versatile and can be easily formed, welded, and fabricated into various shapes and sizes. This flexibility allows for customization and adaptation to specific project requirements, offering designers and engineers a wide range of possibilities. In summary, stainless steel sheets offer corrosion resistance, high strength and durability, heat and fire resistance, hygiene, ease of cleaning, an attractive appearance, and versatility. These properties have made them a popular choice in numerous industries, ensuring their widespread use in various applications.

- Q: Are stainless steel sheets resistant to caustic soda?

- Stainless steel sheets, in general, exhibit resistance to caustic soda. Caustic soda, or sodium hydroxide, is a highly corrosive substance; however, stainless steel is renowned for its exceptional corrosion resistance. Chromium, present in stainless steel, creates a protective oxide layer on the metal's surface, preventing any interaction with caustic soda. Nevertheless, it is crucial to acknowledge that the resistance of stainless steel to caustic soda may vary based on its grade or type. Therefore, it is always advisable to refer to the specific material specifications or seek guidance from a qualified professional to ensure the appropriate selection of stainless steel for applications involving caustic soda.

- Q: Are stainless steel sheets suitable for architectural designs?

- Yes, stainless steel sheets are indeed suitable for architectural designs. Stainless steel is a versatile and durable material that offers numerous advantages for architectural applications. It provides a sleek and modern aesthetic while also being resistant to corrosion, rust, and staining. Stainless steel sheets can be easily shaped, bent, and fabricated into various architectural elements such as cladding, panels, handrails, countertops, and more. Additionally, stainless steel is environmentally friendly, as it is fully recyclable and has a long lifespan, making it an excellent choice for sustainable architectural designs.

- Q: Is there a big price difference between the SUS304 stainless steel plate and the drawing plate?

- Wire drawing is the surface of a steel processing methods, 304 and 201 steel plates can be processed drawing, the price difference is not very large, it will be more than a processing fee. The steel plate after drawing is more likely to rust than the steel plate on the 2B surface.

- Q: How do you remove scratches from mirror-finish stainless steel sheets?

- To remove scratches from mirror-finish stainless steel sheets, you can follow these steps: 1. Clean the surface of the stainless steel sheet with a mild detergent and warm water, then dry it thoroughly. 2. Identify the direction of the grain on the stainless steel sheet. The grain usually runs in one direction and appears as faint lines. 3. Using a non-abrasive stainless steel cleaner or a mixture of baking soda and water, gently rub the scratched area along the grain with a soft cloth or sponge. 4. Continue rubbing in a consistent motion until the scratches start to fade. Avoid applying excessive pressure to prevent further damage. 5. Rinse the surface with clean water and wipe it dry with a soft cloth. 6. If the scratches are still visible, you can try using a stainless steel scratch remover or a metal polish specifically designed for stainless steel. Follow the product instructions and apply it to the scratched area following the grain. 7. Once the scratches are no longer visible, clean the surface again with mild detergent and water, then dry it thoroughly to restore the mirror-finish appearance.

- Q: Can stainless steel sheets be used for chemical processing equipment?

- Yes, stainless steel sheets can be used for chemical processing equipment. Stainless steel is highly resistant to corrosion, making it an ideal material for handling and processing various chemicals. It has excellent strength and can withstand high temperatures and pressures, making it suitable for a wide range of chemical processes. Additionally, stainless steel is easy to clean and maintain, which is crucial for maintaining the purity of chemicals being processed. Overall, stainless steel sheets are a popular choice for chemical processing equipment due to their durability, resistance to corrosion, and ability to meet the stringent requirements of chemical processing environments.

- Q: Are stainless steel sheets good for heat exchanger tubes?

- Yes, stainless steel sheets are commonly used for heat exchanger tubes due to their excellent heat transfer properties and corrosion resistance. Stainless steel has a high thermal conductivity, allowing for efficient heat transfer between fluids. Additionally, it has exceptional resistance to corrosion, which is crucial for heat exchangers that often come into contact with liquids or gases that can be corrosive. The durability of stainless steel sheets also ensures longevity and reliability for heat exchanger tubes, making them a popular choice in various industries such as chemical processing, power generation, and HVAC systems.

Send your message to us

304 Stainless Steel Sheet 304 Stainless Steel Plate 06Cr18Ni9

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords