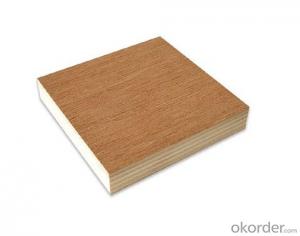

3/4 Inch Plywood 4x8 Sheet H20 Wood Beam for Form Work Construction

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

H20 wood beam for constrution

Raw materials:

Wood material:pine;.poplar,pine,birch,hardwood

2.glue:WBP-phenolic,Melamine waterproof glue

Glue:phenolic or melamine

* Pine LVL flange + pine plywood web

* WBP phenolic resin

Specification:

Flange size: 80X 40mm

Web width: 30mm (3-layer OR multi-layer)

Weight/: 5.00kg-5.20kg/meter

Length avaible:1.25/2.45/2.65/2.9/3.3/3.6/3.9/4.9/5.9/6.6 Meter

Quality assure: Have been applied to all over the world

Surface finishing: Waterproof yellow painting or other color

Packing: Different length loaded differently

Advantage:

Price advantage: 20-30% cheaper than others based on same quality

Design ability: We can offer you a general proposal based on your structural drawings

Beam Timber:

usage:construction Full Pine LVL H20 beam With High Quality :

1> if used abide by the illustrations strictly, it can be reused many times.

2> reducing the cost greatly and avoiding the disadvantage:restily and erosive of iron mould.

3>.solve the problems of leaking and rough surface during constructing process

4> .realizing a higher economic profies.

5> .new technology and materials are being introduced and popularized continuously for construction...........

Supply H20 beam--4 years experience, with competitive price and good quality, they are well selled in all around the world.

* Environment friendly Yellow painting: waterproof, fireproof, rot-proof and frozen-proof

FAQ:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Plywood in the material defects?

- Abnormal structure Any defects caused by abnormal wood construction, such as wrinkles. Wavy pattern. Staggered pattern, spiral pattern and so on.

- Q: National standards for decorative veneer veneer plywood performance requirements

- Its physical and mechanical performance indicators are: moisture content, surface bonding strength, impregnation stripping

- Q: How to use building plywood?

- Building plywood is mainly used in outdoor conditions, such as building decoration and concrete template

- Q: What plywood is now commonly used?

- Melamine gel: moisture-proof, and has a certain resistance to boiling, weather resistance / can be used for outdoor or indoor, but can not often be water immersion

- Q: What is the difference between plywood glue E0E1?

- Phenolic glue: moisture, excellent resistance to boiling, weather resistance / can be used for outdoor or indoor, can withstand outdoor wind and rain.

- Q: What kind of glue is today's plywood?

- if you want to make general indoor wood products, you can use E1 (or even E0) urea formaldehyde;

- Q: Plywood in the processing of defects

- Separation delamination The separation of two adjacent veneers due to lack of glue or poor glue.

- Q: For the plywood environmental advice?

- According to the environmental protection level, the glue used for plywood can be divided into E0 grade, E1 glue, E2 glue (and even E2 level are not reach the unqualified glue)

- Q: What are the shortcomings of plywood

- Plywood is one of the common materials for furniture, one of the three panels of man-made board, but also for aircraft, ships, trains, cars, construction and packaging materials

- Q: Poisoning diagnosis and grading standards

- can also have abnormal growth, reference operating environment investigation and field air concentration determination of benzene, comprehensive analysis

Send your message to us

3/4 Inch Plywood 4x8 Sheet H20 Wood Beam for Form Work Construction

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords