H20 Wood Beam Form Work System for Construction

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

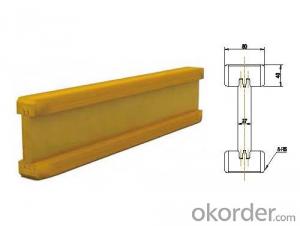

H20 wood beam for form work

Specification:

Wood material:pine

Flange size: 80X 40mm

Web width: 30mm (3-layer OR multi-layer)

Weight/: 5.00kg-5.20kg/meter

Length avaible:1.25/2.45/2.65/2.9/3.3/3.6/3.9/4.9/5.9/6.6 Meter

Quality assure: Have been applied to all over the world

Surface finishing: Waterproof yellow painting or other color

Packing: Different length loaded differently

Glue:phenolic or melamine

Price advantage: 20-30% cheaper than others based on same quality

Design ability: We can offer you a general proposal based on your structural drawings

Beam Timber:

1.material:poplar,pine,birch,hardwood

2.glue:WBP-phenolic,Melamine waterproof glue

3.usage:construction

Features:

1> if used abide by the illustrations strictly, it can be reused many times.

2> reducing the cost greatly and avoiding the disadvantage:restily and erosive of iron mould.

3>.solve the problems of leaking and rough surface during constructing process

4> .realizing a higher economic profies.

5> .new technology and materials are being introduced and popularized continuously for construction...........

Supply H20 beam--4 years experience, with competitive price and good quality, they are well selled in all around the world.

* Pine LVL flange + pine plywood web

* WBP phenolic resin

* Environment friendly Yellow painting: waterproof, fireproof, rot-proof and frozen-proof

FAQ:

① why from okorder?

Okorder is a qualified supplier of all kinds of building matierials in China. All products have been showed in Okorder website are under well controlled by okorder QC team.

All products had been produced under a clear quality standard and the quality is consistence among the shipments.

Okorder has already setted up more than 20 warehouses in different markets to show the products. You are convenient to know the products from your local place and it will help you to make decision easyly.

②How to guarantee the quality of the products?

We have established a perfect quality management system,as for raw material and semi parts all are under strict quality test and we have a IQC system to control the purchases.

QC on site is very strict and all steps of process are measured per drawings. Before delivery, we set a OQC system to make sure each piece meet the standard of order.from design to delivery,

③How long can we receive the product after purchase?

Lead time depending on order quanity, The normal order can be deliveried with 3 weeks.

- Q: defects are divided into four grades

- Appearance grade: ordinary plywood according to the processing of plywood can be seen on the material defects

- Q: The structure of the plywood at the same time meet two basic principles

- So the plywood is usually three, five, seven odd level layer. The name of each layer of the plywood is: the surface of the board is called the table, the inner plate is called the core board;

- Q: Why plywood is cheaper than solid wood

- Without changing the physical properties of wood under the premise of drying, liposuction, paint and other processes can be called solid wood. Plywood (English: Plywood,

- Q: Four levels: Principal, First, Second, Third. Commonly used for one, two, three and so on

- Hard fiber board is also a density board, but its density is above 0.80g / cm3. Divided into one side of the light, the other side of the textured side of the hard fiber board and two-sided hard fiber board two.

- Q: What are the further processing of plywood?

- Direct printing plywood Direct print plywood is printed directly on the plywood surface with simulated wood grain or other patterns.

- Q: Furniture solid wood and plywood which is better? Such as bed `wardrobe` TV cabinet `table

- and the general splint or plywood Need, the number of layers is relatively less, in the balance of internal stress

- Q: What is the type of plywood editing?

- In order to make full use of forest resources to develop plywood production, make the best use of our country's newly developed national standards (draft approval) according to the use of adhesive pull

- Q: What are the processing defects of plywood?

- Patched Plywood Repaired plywood Defects Plywood that has been repaired with a filler or veneer patch.

- Q: Hard fiber board is also a density board

- the same texture direction. Adjacent two-layer veneer grain direction should be the same. The plywood should be the same tree.

- Q: What kind of glue is today's plywood?

- if you want the wood products have a stronger waterproof and moisture-proof performance, you can use E1 (or even E0) melamine glue.

Send your message to us

H20 Wood Beam Form Work System for Construction

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords