2.0mm Thick FRP Panels for Trailer Roofs - Fiber Reinforced Plastic Sheet Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiber Reinforce Plastic Sheet Panel with 2.0 mm Thinkness

Description

FRP sheets are made of fiberglass and polyester resin and continuously molded by machine.

They are characterized by high-light transmittance, light-weight, high-strength, corrosion resistance, impact resistance, anti-ultraviolet, anti-

static, heat preservation and insulation, accurate section dimensions and controllable cutting length. They can be used with various profiling panels and galvanized sheets.

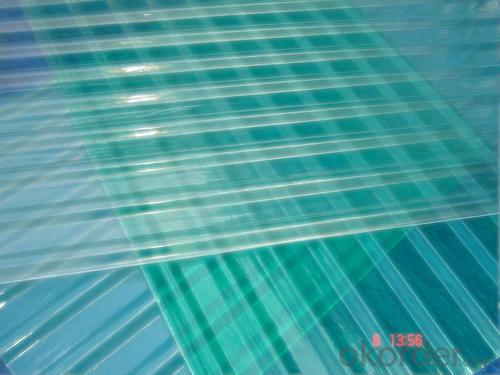

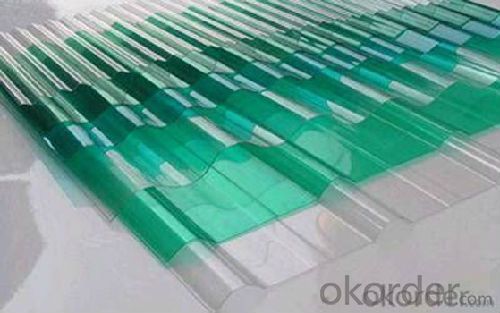

Photos

Product Traits

Good tenacity. No cracking phenomenon when driving nails in roof installation.

Having close combing with color steel plate. Cross-section thickness is uniform. The shape of FRP is consistent with steel plate.

Transmittance loss rate is low. No yellowing phenomenon after long term service.

Thermal expansion coefficient is close to that of steel plate. No cracking and water leakage in nail driving place because of expand with heat and contract with cold.

Light through FRP assumes scattering shape and gentle.

Bright and clean appearance. No distinct air bubble and cracking on FRP.

Anti-ultraviolet and anti-chemistry corrosion.

Anti-aging and anti-pulverization.

Long service life.

Product Advantage

Coated with prevent aging layer

Excellent insulating performance

Easy to maintain.

High strength.

Long service life.

Easy to install.

Good light transmittance.

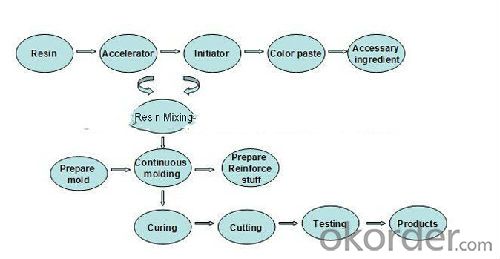

Production Process

Specification

Physical properties:

| Tensile strength | 80-100Mpa |

| Flexural strength | 0-110 Mpa |

| Density | 1.4-1.6g/cm³ |

| Pasteur | ≥40 |

| Heat conductivity factor | 0.67-0.96kv/m.h.°C |

| Temperature range | -40°C—+60°C |

| Water absorption | 24 hours ≤0.32% |

| Wind loading rating | below 8 levels |

| Curing degree | ≥82% |

Product classification:

Plate type | thickness(mm) | width(mm) | |

Flat plate | 0.7-4.0 | ≤1400 | |

Sine wave | 0.7-4.0 | ≤1200 | |

Trapezoidal wave | 0.7-4.0 | Mating with pressure plate | |

Fire resistance | Ordinary type | ||

FAQ

1.Which country do you mainly export to?

A: Our products are very popular in Mid East, India, South East Asia, Latin America, Africa.

2.Q: What’s the advantage of you compared with other suppliers experienced in foreign trade?

A: We have been specialized in FRP products for over decades years and approved by many domestic companies. Except for our quality and price, we’re also able to give you the best service.

3.Q:Can you provide some samples?

A: Yes, of course. We will send you samples for your confirmation before you place firm orders.

- Q: Do FRP roofing panels require a specific type of roof insulation or thermal barrier?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels typically require a specific type of roof insulation or thermal barrier. FRP panels are known for their low thermal conductivity and high insulation properties, which means they can help regulate temperature and minimize heat transfer. However, to maximize their performance and energy efficiency, it is important to install the appropriate insulation or thermal barrier underneath the FRP roofing panels. The specific type of roof insulation or thermal barrier required will depend on various factors such as climate, building codes, and specific project requirements. Common options for roof insulation include rigid foam insulation boards, spray foam insulation, or mineral wool insulation. These materials provide additional thermal resistance and prevent heat loss or gain through the roofing system. Additionally, it is essential to consider vapor barriers in the roofing assembly to control moisture diffusion. Vapor barriers help prevent condensation within the roof system, which can lead to mold or structural damage. The choice of vapor barrier will depend on the specific application and climatic conditions. In summary, while FRP roofing panels offer inherent insulation properties, it is crucial to select and install the appropriate roof insulation or thermal barrier to optimize performance, energy efficiency, and moisture management within the roofing system. Consulting with a professional roofing contractor or engineer can ensure the correct selection and installation of the necessary materials for your specific project.

- Q: Can FRP roofing panels be used for loading docks?

- FRP roofing panels are indeed applicable for loading docks. Renowned for their robustness, long-lasting nature, and ability to withstand different elements like UV rays, moisture, and chemicals, FRP panels prove to be fitting for various purposes, including loading docks. By utilizing FRP roofing panels, one can establish a sturdy and reliable surface to bear heavy loads, thus guaranteeing the safety of both workers and equipment. Moreover, the lightweight and effortless installation of FRP panels make them a convenient option for constructing or renovating loading docks.

- Q: Do FRP roofing panels have any specific warranty coverage?

- Yes, FRP roofing panels typically come with specific warranty coverage provided by the manufacturer. The warranty coverage may vary depending on the brand and type of FRP roofing panel, but it often includes protection against manufacturing defects, material failure, and structural integrity for a specified period of time. It is important to review the warranty terms and conditions provided by the manufacturer to understand the specific coverage and any limitations.

- Q: Are FRP roofing panels suitable for hospitals or healthcare facilities?

- FRP roofing panels are a great option for hospitals or healthcare facilities due to their many advantages. Firstly, they are incredibly durable and can withstand corrosion, UV rays, and chemicals, which is essential for maintaining a sanitary environment. They can also handle frequent cleaning and sterilization procedures without any damage. Secondly, FRP panels are lightweight yet strong, making them easy to install and reducing the strain on the building structure. They can withstand extreme weather conditions and natural disasters, ensuring a secure and reliable roofing solution. In addition, FRP panels provide excellent thermal insulation, helping to regulate the temperature and reduce energy consumption. This creates a comfortable and energy-efficient environment for patients' well-being and recovery. Furthermore, architects and designers have the freedom to choose from a variety of colors and finishes for FRP panels, allowing them to match the aesthetic requirements of the healthcare facility. The panels can also be customized to include skylights or windows, providing optimal natural lighting and ventilation. Lastly, FRP panels require minimal maintenance, resulting in lower costs associated with roof upkeep. They are resistant to mold, mildew, and pests, ensuring a clean and healthy environment for hospitals or healthcare facilities. Overall, FRP roofing panels offer numerous advantages, including durability, lightweight yet strong composition, thermal insulation, customization options, and low maintenance requirements. These qualities make them an excellent choice for hospitals or healthcare facilities, providing a safe, hygienic, and comfortable roofing solution.

- Q: Do FRP roofing panels require any specific type of underlayment?

- FRP roofing panels necessitate a particular underlayment. The underlayment employed for FRP roofing panels must possess moisture resistance and furnish a smooth surface for panel adherence. Typically, it is recommended to use a high-quality moisture barrier or vapor retarder, such as a synthetic roofing underlayment. This aids in preventing moisture infiltration and panel damage, guaranteeing their durability and performance. Moreover, the underlayment should be compatible with the adhesive or sealant employed to affix the FRP panels securely and prevent water leakage. To determine the specific underlayment requirements for your FRP roofing panels, it is advisable to consult the manufacturer or a professional roofing contractor, as different panels and applications may necessitate varying specifications.

- Q: Are FRP roofing panels resistant to warping or sagging?

- FRP roofing panels are known for their exceptional resistance against warping or sagging. This is due to their high strength-to-weight ratio, enabling them to retain their structural integrity even when subjected to substantial loads or variations in temperature. The inclusion of fiberglass reinforcement in FRP panels contributes to their remarkable stiffness and rigidity, thus preventing any noticeable signs of warping or sagging over time. Moreover, the design of FRP panels takes into account the ability to withstand severe weather conditions, including strong winds, heavy rainfall, and intense sunlight, thereby further ensuring their resistance against warping or sagging. In conclusion, FRP roofing panels offer a durable and dependable solution that can retain their shape and structural integrity over an extended duration.

- Q: Are FRP roofing panels resistant to discoloration?

- Yes, FRP roofing panels are generally resistant to discoloration due to their durable and UV-resistant properties.

- Q: Are FRP roofing panels suitable for curved roofs?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be suitable for curved roofs. FRP panels are known for their flexibility and durability, making them a popular choice for a wide range of roofing applications. They can easily be molded to fit the unique contours of curved roofs, providing a seamless and aesthetically pleasing finish. Additionally, FRP panels are available in various thicknesses and profiles, allowing for customization to meet specific design requirements. This flexibility in design makes FRP panels an excellent choice for curved roofs, as they can be tailored to match the curvature of the roof precisely. Moreover, FRP roofing panels offer several advantages for curved roofs. Firstly, they are lightweight, reducing the load on the structure and making installation easier. Secondly, FRP panels are resistant to corrosion, UV rays, and extreme weather conditions, ensuring long-lasting performance and minimal maintenance. Additionally, FRP panels offer excellent insulation properties, providing energy efficiency benefits for the building. Overall, FRP roofing panels are a suitable option for curved roofs due to their flexibility, durability, customization options, and numerous advantages.

- Q: Are FRP roofing panels resistant to electrical conductivity?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are resistant to electrical conductivity. The fiberglass material used in these panels does not conduct electricity, making them a safe choice for roofing in areas where electrical conductivity may be a concern.

- Q: Can FRP roofing panels be customized in terms of size and color?

- FRP roofing panels have the capability to be tailored according to size and color preferences. FRP, an abbreviation for fiberglass reinforced plastic, is a versatile material that can be easily shaped and constructed to fulfill specific needs. When it comes to size, FRP roofing panels can be produced in various lengths, widths, and thicknesses to perfectly fit the dimensions of a building or project. Moreover, FRP panels can be uniquely crafted in a variety of colors to align with the customer's aesthetic taste or branding requirements. The vast customization options available for FRP roofing panels have made them a highly sought-after choice for a wide range of applications, including industrial and commercial buildings as well as residential projects.

Send your message to us

2.0mm Thick FRP Panels for Trailer Roofs - Fiber Reinforced Plastic Sheet Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords