Frp Roof Panels - Corrosion Resistance FRP Roofing Tile Balcony Roof Covering

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m

- Supply Capability:

- 40000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

Fiberglass corrugated sheet is usually used in construction site as protecting facility. It is dagarous for workers in building site since you never know if there is something hard drop down from the high area. So corrugated sheet is installed for preventing the stuff dropping down to hurt people.

Besides, it could also applied as the roof of the constructions

FEATURES

1) The fiberglass content of new generation greenhouse panel has been improved by 18.3%.

2) Weather resistant and Self-clean ability.

3) Excellent yellowness resistance.

4) Strong impact resistant and low bending rate.

5)Withstand extreme temperature from -38 degree to +110 degree for a long time

6) Aging resistant: specified F4 film added on surface and gel coat makes it endurable for long.

7) More strengthened, safer, cleaner and more economical greenhouse panel.

8) Mainly serve the big factory, warehouse, super markets and other steel-structured project.

SPECIFICATION

Name | FRP Roofing |

Material | Fiberglass |

Width | 880mm/1050mm |

Effective width | 800mm/960mm |

Wave length | 160mm |

Wave height | 30mm |

Pitch | 220mm |

Thickness | 3/2.5mm |

Length | Customized but must be a multiple of wave pitch |

Color | Purplish Red, Brick Red, Grey, Green, Blue or customized |

Application | House, villa, pavilions, industrial plants, large warehouses, supermarkets, stadiums etc |

MOQ | 1000 Square meter |

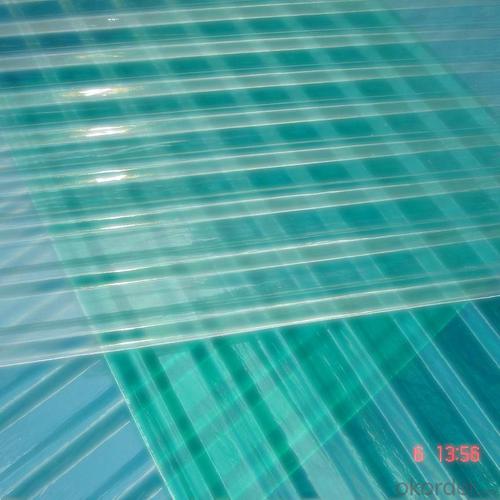

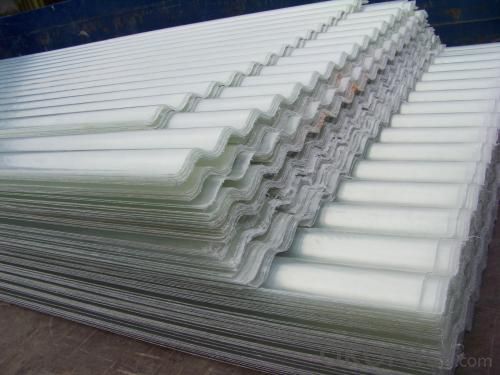

PICTURES

- Q: Are FRP roofing panels easy to clean?

- FRP roofing panels are typically effortless to clean. Fiberglass Reinforced Plastic, or FRP, is a sturdy and low-upkeep substance. These panels possess a sleek exterior that repels dirt, dust, and other particles. To clean them, one usually only needs to rinse with water and, if needed, apply a mild detergent. Furthermore, FRP roofing panels do not tend to stain or lose color, making maintenance relatively trouble-free. Nevertheless, for the best outcome, it is advisable to adhere to the cleaning instructions provided by the manufacturer.

- Q: Are FRP roofing panels compatible with solar panels?

- Yes, FRP roofing panels are compatible with solar panels. The lightweight and durable nature of FRP roofing panels make them an ideal choice for supporting and protecting solar panel systems. Additionally, the translucent properties of FRP panels allow for effective sunlight penetration, enhancing the overall efficiency of the solar panels.

- Q: Are FRP roofing panels resistant to impact from falling objects?

- Known for their high impact resistance, FRP (Fiberglass Reinforced Plastic) roofing panels are commonly utilized in industrial, commercial, and agricultural settings. These panels are designed to endure various environmental conditions. However, the level of impact resistance may vary depending on factors such as thickness, quality, and manufacturer specifications. In essence, FRP roofing panels are engineered to possess remarkable durability, enabling them to withstand the force of falling objects. They are comprised of multiple layers of reinforced fiberglass and a resin matrix, which provide strength and rigidity. This composition effectively disperses the impact force over the entire surface of the panel, reducing the risk of damage or breakage. It is crucial to note that while FRP roofing panels are engineered to withstand normal impacts, they may not be entirely impervious to all types of falling objects. Objects that are excessively heavy or sharp, such as large tools or metal items, have the potential to cause damage upon impact. To ensure optimal performance and longevity, it is advisable to consult the manufacturer's guidelines and specifications specific to the FRP roofing panels being used. Additionally, proper installation, regular maintenance, and periodic inspections are essential for identifying and addressing any potential issues arising from impacts or other factors. These practices guarantee the enduring durability and impact resistance of the FRP roofing panels.

- Q: Can FRP roofing panels be used for libraries?

- Yes, FRP roofing panels can be used for libraries. FRP (Fiberglass Reinforced Plastic) roofing panels are durable, lightweight, and have excellent resistance to weathering and UV radiation. These qualities make them suitable for various applications, including libraries, where they can provide long-lasting protection against the elements while allowing natural light to enter the space. Additionally, FRP panels are available in different colors and designs, allowing for customization to match the aesthetics of the library.

- Q: Are FRP roofing panels resistant to insect infestation?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are generally resistant to insect infestation. The material used in FRP panels is not attractive to insects, and their smooth surface makes it difficult for insects to find any crevices or gaps to enter and infest the panels. Additionally, FRP panels are typically treated with a protective coating that adds an extra layer of insect resistance. However, it is important to note that while FRP panels themselves are resistant to insect infestation, surrounding areas such as roof edges, eaves, and vents may still be vulnerable to insects. Therefore, it is recommended to properly seal and maintain these areas to prevent any potential infestation.

- Q: Are FRP roofing panels compatible with roof vents or exhaust fans?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are compatible with roof vents or exhaust fans. These panels can be easily customized and modified to accommodate the installation of roof vents or exhaust fans without compromising their functionality or integrity.

- Q: Are FRP roofing panels resistant to high winds?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are generally resistant to high winds. The strength and durability of FRP material make it capable of withstanding strong winds and preventing damage to the roof. However, it is important to ensure proper installation and anchoring of the panels to maximize their wind resistance.

- Q: Can FRP roofing panels withstand extreme weather conditions?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are known for their durability and ability to withstand extreme weather conditions. One of the key advantages of FRP roofing panels is their high impact resistance, which allows them to withstand strong winds, heavy rain, hail, and even extreme temperature fluctuations. FRP panels are made of a composite material that combines fiberglass and resin, providing them with excellent strength and resilience. Furthermore, FRP panels are also UV resistant, which means they can withstand prolonged exposure to sunlight without fading or degrading. Overall, FRP roofing panels are designed to endure harsh weather conditions, making them a reliable choice for various applications.

- Q: Can FRP roofing panels be used for hospitals?

- Yes, FRP roofing panels can be used for hospitals. FRP (Fiberglass Reinforced Plastic) roofing panels are a durable and lightweight option that can provide excellent insulation and weather resistance. They are commonly used in various industries, including healthcare facilities such as hospitals, due to their ability to withstand harsh conditions, offer energy efficiency, and require low maintenance. Additionally, FRP panels can be customized to meet specific design requirements, making them suitable for hospitals with unique architectural needs.

- Q: Are FRP roofing panels resistant to graffiti?

- FRP roofing panels are typically resistant to graffiti due to their durable and non-porous surface. The panels are made from a combination of fiberglass and resin, which creates a strong and smooth finish that is difficult for graffiti to adhere to. Additionally, FRP panels can be manufactured with a protective gel coat that further enhances their resistance to graffiti. This gel coat acts as a barrier, preventing paint and other substances from penetrating the surface of the panels. However, it is important to note that no material is completely immune to graffiti, and determined vandals may still be able to deface FRP roofing panels with certain types of graffiti materials. In such cases, prompt removal and cleaning of the graffiti is recommended to maintain the panel's appearance and prevent further damage.

Send your message to us

Frp Roof Panels - Corrosion Resistance FRP Roofing Tile Balcony Roof Covering

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m

- Supply Capability:

- 40000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords