12T Loading Capacity Tower Crane TC7034-F-52.4

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Description:

Tower crane 7034 is used to lift building material such as concrete, steel bars vertically and horizonally.

All tower cranes consist of the same basic parts:

1. The base is bolted to a large concrete pad that supports the crane.

2. The base connects to the mast (or tower), which gives the tower crane its height.

3. Attached to the top of the mast is the slewing unit (large ring-gear and motor) that allows the

crane to rotate.

4. Attached to the slewing unit is the jib (or boom), the machinery arm, the counterweights

and, the Operators cabin

Features:

Typehammer head

Max loading capacity: 12t

Tip loading:3.4t

Jib length:70m

Free standing height:50m

Mast section:2mx2mx3m

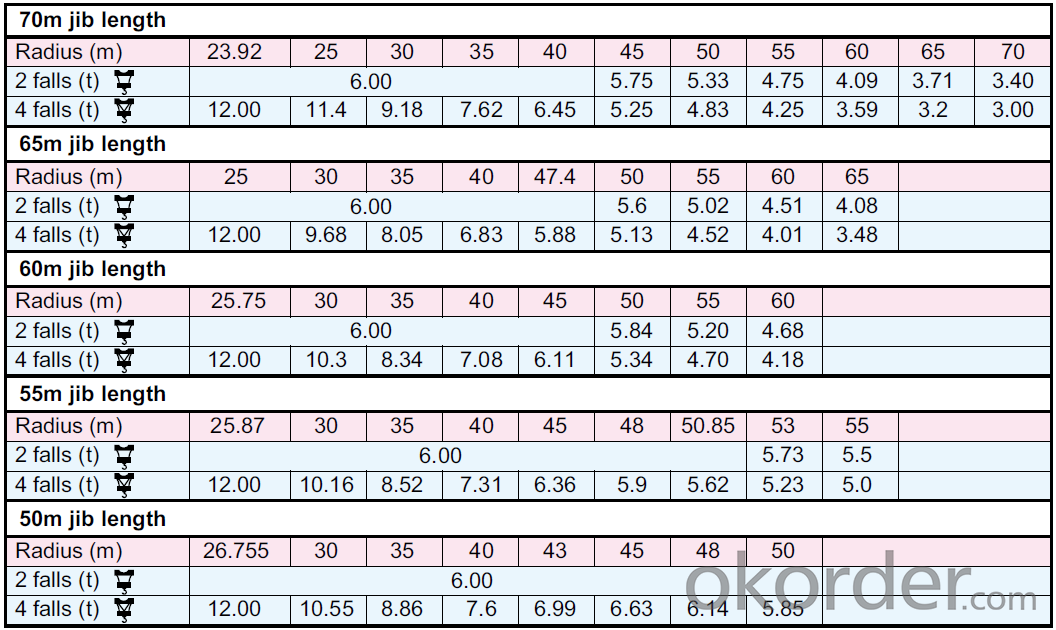

Loading Diagram:

FAQ

1. The foundation type available: fixed, undercarriage, travelling type

2. The life time of tower cranes: usually 10 years

3. Packaging:each unit needs 6x40HQ for free standing height

4. Shipping time: Usually around 35 days after receipt of advance payment

5. Payment term: TT, L/C

TRUEMAX was established in 2003 at Hangzhou, China. In the past 10 years, TRUEMAX has established over 10 manufacturing base, to offer the one-stop services in construction machinery filed, including R&D, designing, manufacturing, quality control and delivery.

With core principle of “True to Quality, Ture to Customer”, our product has been exported to more than 100 countries with high customer appreciation & brand popularity.

TRUEMAX provide the full series of construction machinery and one-stop overall solution. Our product range covers pre-fabrication including aggregate crushing, dedusting and block making; concrete series including mixing, batching, pumping & placing; construction series, such as tower crane, building hoist, suspension platform and lifting basket; light construction machinery, including compacting, cutting, surface finishing machines & rebar processing machines.

Especially the concrete placing boom, we’re the No. 1 in term of products variety, with top quality placing boom of placing radius ranging from 10 meters to 51 meters over 10 different series, the excellent quality & performance has been tested & approved by being used in lots of world famous high buildings.

The manufacturing base of TRUEMAX adopts 6S management system. Quality control system are implemented strictly in the whole procedures, including components purchasing, fabricating and manufacturing, packing and dispatch pre-inspection, ensuring the perfect quality assurance for all of our products. With international certificates like ISO9001:2008, CE & SGS, TRUEMAX guarantee the international first-class level for all of our products.

At present, TRUEMAX is the“Grade A Export Enterprise of China Customs”, “Famous Export Brand of Zhejiang”, “ Famous Export Brand of Hangzhou”, “High & New Technology Enterprise of Hangzhou”, “Top 100 innovation-type foreign trade enterprise of Hangzhou”&“ Key enterprises of Xiacheng district, Hangzhou”, with support from Zhejiang Public Foreign Trade Service Platforms consecutively in 2012 and 2013.

“Quality achieves outstanding success, innovation leads the bright future”, our working principle has leads the rapid expansion of TRUEMAX, with branches and spare parts distribution centers established oversea step by step. We’re targeting to complete the global layout of TRUEMAX Agent within next 2 years, and “TRUEMAX 6S” stores within 5years.

In the coming days, TRUMAX will continue to forge ahead, make our best efforts to create the best platform for career performance, as well as to realize the maximized mutual benefit with all TUREMAX friends, partners, agents & clients.

“View Broad, Ambitions Boundless”, at a new height, we wish to join hands with all the ambitious friends together, contributing to the consummation of the first-class quality construction machinery industry, and creating the new glory constantly.

- Q: I understand the Crane stances and know there are more than one. I am referring to the single leg crane stance. I also know that stances are only used briefly. But I am curious, does this stance have any bunkai applications? Or is it only useful against dodging a kick or preparing to kick?

- What you call Crane stance with a single leg in contact with the ground actually has many applications besides kicking. BTW: As I understand it, doesn't bunkai mean application? The single leg stance is also a mean to focus power from one rooted leg to your punch. The mechanics for a kick from the crane stance can also be used in a punch. It is actually the same. The force you exert from that single leg against the ground or your root-ness is transmitted through your body to the fist or even a block. Think about a situation where you are rapidly transferring your weight from one leg to the other such as when you are backpedaling or moving quickly and see an opening to strike. The power for that strike can still be generated by that one single leg in that instance when it is properly rooted. So rather than planting both legs first and then strike, you can do so with just that single leg that is already in place.

- Q: Calculate the work the crane performs.

- Crane work = weight to be lifted x 6.95 m Weight to be lifted = 2.75x10^3 N + 1.20 m^3 (2.00 x 10^3 kg/m^3) (9.8) = 2750 + 23520 = 26270 Therefore, Crane work = 26270 x 6.95 = 182576.5 J

- Q: I'd take Denny Crane he's ruthless

- Denny Crane

- Q: Are tower cranes the same as tower cranes?

- Tomato, you tomato, potatoes, you potatoTalent exchange of tower crane and tower crane

- Q: The Wayfarerby Stephen Crane The wayfarer, Perceiving the pathway to truth, Was struck with astonishment. It was thickly overgrown with weeds. Ha, he said, I see that none has passed here In a long time. Later he saw that each weed Was a singular knife. Well, he mumbled at last, Doubtless there are other roads.I understand that it is about a person taken the easy way out, but what other underlying meanings are there?

- A Wayfarer is an aimless wanderer. It's often more comfortable and flattering to the ego to think about a goal rather than to have the conviction to actually go through with achieving it. It's painfully difficult and takes a lot of strength to create your own path in life. People like to talk about how great they are, but ultimately, when faced with the truth they will opt to go along with the crowd.

- Q: My dad has some old tools and he is wondering if the company is still around, or what happened to it. A yahoo search revealed little.

- Found on - www.lathes .uk/boicecrane/ Boice-Crane - USA Boice-Crane (Wilton Division) made various types of power tools, including a selection of wood lathes intended for amateur and educational use, and in the 1940s and early 1950 their range included, amongst others, the two amateur and one professional or educational machines illustrated below. The more robust lathe of the amateur pair had a 50 inch long bed with 10 swing and able to take 34 between centres; the 4-step V pulley in the headstock could be driven from either from the rear, or underneath. The bed, which had a gap able to swing 14, was internally ribbed and machined on its top surface. The No. 1 Morse taper tailstock was fitted with self eject for the centre. The double-ended spindle was 1.25 inches in diameter and ran on ball bearings - whilst the single faceplate contained two different diameter, left and right-hand threads so that it could be screwed onto either end. The lathe weighed 115 lbs, so, despite an insubstantial appearance, must have been a reasonably robust machine. The other bench lathe had a bed built from two steel channel sections - with the most elementary type of headstock and tailstock. The capacity was 10 x 30, the weight 30 lbs and the headstock spindle carried a 4-step, overhung, V-belt pulley. The company are now: Gothenburg Manufacturing Co., P.O. Box 308, Gothenburg, NE 69138 Phone: (308)537-3628 and - Boice-Crane Parts, 2442 Densmore Drive, OH 43606 Phone: (419)531-1113

- Q: Hi there!I was planning on making an electromagnetic crane, and I already understand how the electromagnet works. Its for the science fair in two weeks, but they asked us to make our projects soon.But I not sure hot to build the crane itself, any ideas?

- Electromagnetic Crane Science Project

- Q: What kind of force acting in the brake system which encounter the lifting material force and to maintain its level.

- Cranes work using hydraulics and cables. The cables are wrapped around pulleys and the pulley is turned using hydraulic power. The brake system is simply stopping the pulley from turning by reducing power. The hydraulic system typically will turn a series of gears which in turn spins the pulley that the cable is wrapped around. It's different than a brake system say on a car where when you hit the brakes, pads squeeze on the interior of the wheel rim slowing it down. Cranes you just reduce power and stop the pulley from turning. They also have emergency stops. Older cranes have wedges that would be released onto the cable and then the wedges would grab the cable and slip into a ring. The narrow end of the wedges would slip into the ring first and then as the wedges increased in diameter the grip on the cable would get tighter and then stop the cable from moving. They also have systems on the pulleys to stop the pulley from spinning. They essentially work the same way as a car break. When the emergency brake is triggered, pads will squeeze on the rim of the pulley to stop it. These mechanisms work by friction. They could also have holes around the pulley and a steel pin would be pushed into one of the holes to stop it from spinning. Of course if the force of the weight exceeded the strength of the pin, it would shear.

- Q: Vtwin doc helped me out with this dam thing recently Im thinking he has the 411! So here goes: My friends coil went bad and we used a single fire coil on a dual fire ignition. V twin doc showed me how to do that. But it still doesnt quite run proper. So here are the settings:Its set at 5900 R.P.M. limit,with advance slope at 9.the rear cylinder is set at 0.Its set on dual fire,its set on electric start.and its set on multi spark not single.Its a crane fireball hi 4e model 8-3100. It cranks for a bit before starting and runs a little rough at low R.P.M. ran just fine with the stock coil.

- Hey Adam, Hmmm....not too sure about that one. But give this a shot. Check the threaded inserts in the coils (screw terminals), I have seen them break loose PLEASE tell me you are NOT running in race mode!!!.....Street bike run MUCH MUCH better with a VOES....adjust the VOES to 6 of vacuum...email if you don't know how to adjust them, it seems to be a little known fact to almost everyone that they ARE adjustable. Check the connections to the voes also. Reset set the static timing....set the TDC mark in line with front of the timing hole, this will be at 32 degrees, EVO's and TC's run better SLIGHTLY retarded. I would also throw on a fresh set of CARBON CORE plug wires. The Cranes don't seem to like Taylor style (spiral wound) wires. Check to see how it runs. Then try switching back to single spark and see what happens. If nothing changes, I am not too sure what it could be, other than the coil itself, without being able to see it first hand. If you do figure it out, let me know what you found.

- Q: Who was the guy called the Headless Horseman in the story of Ichabod Crane?

- In the Washington Irving version of the story (which may be the original, I don't know if he based it on an earlier story or not), the Horseman is the ghost of a Hessian mercenary who fought died during the American Revolutionary War (if you don't know about this, Hessians were German mercenaries that were hired by the British). However, in this story, the guy never is given a name. He might be given a name in other versions of the story, but I am only really familiar with the Washington Irving version the various movies based on that story.

Send your message to us

12T Loading Capacity Tower Crane TC7034-F-52.4

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords