1260 Refractory Ceramic Fiber Blanket

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Grade: | HP (High Pure) | Application: | Refractory | Thickness: | 6-50mm |

| Width: | 610mm,610mmx2 | Length: | 3660/4880/7320/9760/14640mm | Chemical Composition: | Al2O3:49% |

| Ultimate Strength (≥ MPa): | 0.08-0.12Mpa(128kg/m3) | Working Temperature: | 1100C | Fiber Diameter: | 3~5um |

| Shrinkage (1800 ℉, 3h): | -3 (hours) | Thermal Conductivity: | 0.09-0.16w/m.k(400-800C) | Model Number: | Ceramic Fiber Blanket |

| Brand Name: | Place of Origin: | (Mainland) | Color: | Pure white | |

| Certificate: | ISO9001:2000, MSDS, CE, REACH | Type: | Ceramic fiber blanket | Application of ceramic fiber blanket: | Refractory furnace lining,Furnace refractory,roof heat insulation seal |

| Operation Temp(C°): | 1100 | Width(mm) of the ceramic fiber blanket:: | 610, 1220 | Length(mm) of the ceramic fiber blanket:: | 14640, 9760, 7320, 4880, 3660 |

| thickness(mm) of ceramic fiber blanket:: | 6,13, 19, 25, 38, 50 | Chemical Composition (%): | Al2O3(45-46%) Al2O3+SiO2(≥98%) | Product Name: | Refractory Ceramic Fiber Blanket |

Packaging & Delivery

| Packaging Detail: | PE Bag,Carton box 525rolls/1x40HQ for ceramic fiber blanket products |

| Delivery Detail: | Within 15 days for ceramic fiber blanket |

| Ceramic fiber blanket Information | ||||||||||

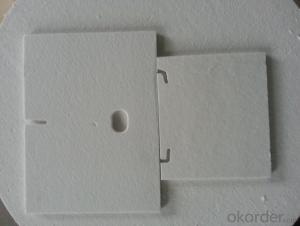

CCEWOOL ® Ceramic Fiber Blanket is a new type of fire-resistant insulation materials in white and tidy size, with integrated fire resistance, heat separation and thermal insulation functions, containing no any binding agent and maintains good tensile strength, toughness, and the fibrous structure when used in a neutral, oxidized atmosphere. CCEWOOL ® Ceramic Fiber Blanket can restore to original thermal and physical properties after drying, without any impact by oil corrosion. All CCEWOOL ® Ceramic Fiber Blankets are made though spun fiber production, and the corresponding fiber bulk has the same excellent chemical stability, high room-temperature strength and strength after burnt, which is widely used in various sectors of refractory, insulation, thermal insulation field. | ||||||||||

| Product Brief Introduction | ||||||||||

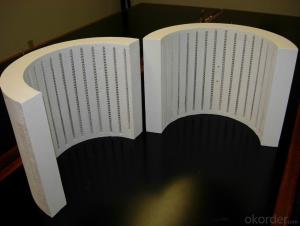

| Item:Ceramic Fiber blanketSTANDARDS OF TYPEBlanket:Density: 96kg/m³,128kg/m³,160kg/m³Thickness:6mm,13mm, 19mm, 25mm, 38mm, 50mmWidth: 610mm,1220mm21840x610x6mm, 14640x610x12.5mm, 7320x610x25mm, 4800x610x38mm, 3600x610x50mm1/4''x24''x860'', 1/2''x24''x600'', 1''x24''x300'', 1-1/2''x190, 2''x24''x140''Classification Temperature1050°C, 1260°C, 1400°C, 1450°CApplications:Soaking pit sealsExpansion joint sealsAnnealing cover sealsFire protection systemsHigh temperature gasketingGlass furnace crown insulationInvestment casting mould wrappings Incineration equipment and stack linings Kiln and furnace insulationInsulation for steam and gas turbinesRemovable insulationHigh temperature pipe and casting mold insulation.Repair, insulation and linings for furnaces, kilns, ovens, generators, reformers, boilers,Duct and turbine insulation- Forging furnaces linings- High-temperature seals and gasketFurnace door seals -Glass furnace crown insulation -Heat processing equipmentsCar bottom furnace lining insulation -Fire protective insulation or liningsAdvantagesResistance to high temperature Low thermal conductivity Resistance to thermal shockExcellent corrosion resistanceLow shot content Low heat storage High tensile strength Good sound absorption Double needled blanket -Low density -Low thermal conductivity -Shorter heat up and cool down timeResilience and resistance to thermal shock -Flexible and easy to cut and installContain no organic binder -Asbestos freePacking:In plastic bags and then in cartonsDelivery TimeWithin 15 days after received the deposit.CertificateISO, CE, REACH, MSDS can be providedThe third party inspectionBV, TUV, SGS

| ||||||||||

| Technical Data of ceramic fiber blanket | ||||||||||

| Classification(°C)Types1050 Ordinary Ceramic Fiber Blanket1260 Standard Ceramic Fiber Blanket1260 High-purityCeramic Fiber Blanket1400 High AluminiaCeramic Fiber Blanket1450 ZirconiaCeramic Fiber BlanketOperation Temp(°C)950°C(1742°F)1050°C(1922°F)1100°C(2012°F)1200°C(2192°F )1350°C(2462°F)Density(kg/m3)64-160Permanent Change on Heating(%)950°Cx24h≤-31050°Cx24h≤-31100°Cx24h≤-31200°Cx24h≤-31350°Cx24h≤-3Theoretic Heat Conductive Co-efficientW/(m·k)(128kg/m3)0.15(600°C)0.22(800°C)0.12(600°C)0.20(800°C)0.12(600°C)0.20(800°C)0.1(600°C)0.20(800°C)0.16(800°C)0.20(1000°C)Tensile Strength(Thickness 25mm)(Mpa)(25mm)≥0.04≥0.05≥0.05≥0.04≥0.06ChemicalCompositionAl2O3(%)4445-4647-4952-5539-40Al2O3+SiO2(%)≥96≥98≥99≥99-ZrO2(%)----15-17Al2O3+SiO2+ZrO2(%)----≥99Fe2O3(%)≤1.0≤0.8≤0.2≤0.2≤0.2Na2O+K2O(%)≤0.4≤0.3≤0.2≤0.2≤0.2CaO+MgO≤0.3≤0.2≤0.2≤0.2≤0.2 | ||||||||||

| Why choose our products? | ||||||||||

ceramic fiber blanket is made of ceramic long fiber that is produced by the melting of very pure raw materials in double surfaceneeding process without binders and with good stability in a large range of temperature. The process of double surface needing increase interweaving and tensile strength. | ||||||||||

- Q: Definition of ceramic fiber

- Ordinary ceramic fiber, also known as aluminum silicate fiber, because one of its main ingredients is alumina, and alumina is the main component of porcelain, so it is called ceramic fiber. The addition of zirconia or chromium oxide can further increase the utilization temperature of the ceramic fiber.Ceramic fiber products refers to the use of ceramic fiber as raw materials, through processing made of light weight, high temperature resistance, good thermal stability, thermal conductivity of industrial products, low heat resistance of small and mechanical vibration etc., specially used for all kinds of high temperature, high pressure, easy to wear in the environmentCeramic fiber product is a kind of excellent refractory material.

- Q: What is the process of producing ceramic fiber mats?

- Specifications:Diameter 10mm-- infinityProduct features:1) the continuous use temperature can reach 1000 DEG C, and the service temperature can reach 1260 DEG C for a short time.2) has good acid and alkali corrosion resistance and aluminum, zinc and other molten metal melting ability.

- Q: What is ceramic fiber?

- 1, ceramic fiber is a fibrous lightweight refractory material, has the advantages of light weight, high temperature resistance, good thermal stability, low thermal conductivity, specific heat and resistance to mechanical vibration, and thus in machinery, metallurgy, petroleum, ceramics, glass, electronics and other industries have been widely used.2, ceramic fiber products is a good refractory. The utility model has the advantages of light weight, high temperature resistance, small heat capacity, good insulation and heat insulation performance, good high-temperature heat insulation performance, no toxicity, etc..3, light quality, good heat insulation performance, good thermal stability, good chemical stability, easy processing and convenient construction. It is neither wear-resistant nor collision resistant, can not resist the erosion of high-speed airflow, and can not resist the erosion of molten slag.

- Q: What is ceramic fiber paper?

- Ji'nan Huolong ceramic fiber paper is made from high purity ultrafine ceramic fiber cotton by dispersing agent evenly dispersed, high temperature binder and a dilution ratio of the mixed, heated by microwave drying was prepared.

- Q: What ceramic fiber profiled products are needed in steel mills? What's the name?

- Ceramic fiber and nano heat insulation board are used for heat insulation, and in the steel plant are generally used for ladle, tundish insulation, and now can also be made of nano insulation products special-shaped products.

- Q: Refractory ceramics and other refractory materials manufacturing is a big industry?

- Also belong to the building materials industry, glass industry and other industries, are Rong Sheng refractories industry ah.

- Q: What brand of ceramic fiber products is best?

- The quality of the above products can be highlighted from two aspects:1, large-scale production2, the application of advanced technology3, brand awareness of the high and low

- Q: The product characteristics of ceramic fiber cloth?

- It has good low temperature and high temperature strength;Non-toxic, harmless, no adverse effects on the environment;Convenient construction and installation;

- Q: Can a series of ceramic fiber products be used in combination?

- Ceramic fiber products is referred to, including ceramic fiber, ceramic fiber blanket, ceramic fiber, ceramic fiber module, ceramic fiber paper, ceramic fiber folded block, ceramic fiber blanket, ceramic fiber, special-shaped pieces of Castable Ceramic fiber, ceramic fiber spray coating, ceramic fiber cloth, ceramic fiber, ceramic fiber rope dozens of products, ceramic fiber products are combined to use in the process of using.

- Q: ceramic fiber

- Advantages of ceramic fiberRefractory ceramic fiber material is a lightweight and efficient thermal insulation material. It has the following advantages over traditional heat insulation materials:Ceramic fiber as lining, low volume density: ceramic fiber lining than light heat insulation brick lining light more than 75%, lighter than light castable lining light 90% to 95%. If using fiber lining, it can greatly reduce the steel structure load and prolong the service life of the furnace.The heat capacity (heat storage capacity) of ceramic fiber lining is low: the heat capacity of ceramic fiber is only about l/10 of light heat resistant lining and light castable lining, and the heat capacity of lining material is proportional to the weight of lining. Low heat capacity means the furnace in the reciprocating operation absorb less heat and heating speed, greatly reducing the operational control of the temperature in energy consumption, especially for heating furnace and furnace, furnace shutdown has obvious energy saving effect.Ceramic fiber lining: low thermal conductivity of ceramic fiber lining in the average temperature of 400 degrees, the thermal conductivity is less than 0.1w/mk, the average 600 degrees less than 0.l5 w/mk, average 1000 degrees less than 0.25w/mk, about l/8 as a lightweight clay brick, lightweight refractory lining l/10, adiabatic effect.The construction of ceramic fiber lining is simple: no expansion joints are needed during construction, and the construction personnel can be started after the basic training. The technical factors of construction have little influence on the insulation effect of the lining. Ji'nan Sheng Yang

Send your message to us

1260 Refractory Ceramic Fiber Blanket

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords