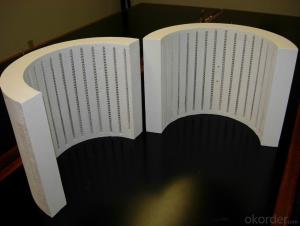

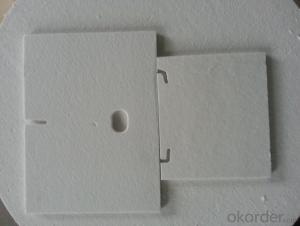

customer-tailor ceramic fiber board used for water heater

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SpecificationsCeramic Fiber Board for Combustion Chamber Insulation

1.Working Temp:1200C

2.Density:320kg/m3

3.Material:Alumina Silicate

General Information

CMAX ceramic fiber board are manufactured in a wet vacuum forming process by blending the chopped ceramic fiber with inorganic or organic binders for excellent abrasive resistance at high temperature.

The products are classified as STD, HP, HA, and HZ respectively corresponding to different maximum service temperature 1000℃,1100℃,1200℃ and 1350℃

Feature

Low thermal conductivity

Excellent thermal shock resistance

Excellent chemical stability

Even density and thickness

Non standard sizes are available upon request

Application

Hot air duct ling

Shuttle kiln with high gas velocity

Laboratory furnace

Kiln car insulation

Die-cut high temperature seal

Application

It has great anti-mechanical-destruction capacity, and can be applied as materials which require tenacity, self supporting ability,and thermal insulation ability. More specifically, it can be used as : thermal insulation lining and back lining in pusher kilns, ladle furnaces, bell-cover kilns,tunnel kilns, roller kilns, and aluminum melting kilns, and thermal treatment furnaces; high-temperature fire damper board and thermal insulation for kiln cars;

thermal insulation for various high-temperature industrial kilns and furnaces.

CERAMIC FIBER BOARD ---STD

Classification Temperature (℃) 1260

Working Temperature (℃) 1000

Color White

Bulk Density (kg/m3) 240-300

Thermal Conductivity(W/m.k)

400℃ 0.067

600℃ 0.094

800℃ 0.136

1000℃ 0.152

1200℃ 0.190

1300℃ -

Thermal Shrinkage 24hrs (%) 1200℃

-3.3

Chemical Composition (%)

Al2O3 45-47

Al2O3+ SiO2 97-98.5

- Q: Slag ball content of ceramic fiber material?

- 2800 ~ 3200kg/m the data of fand, right?Chasing the answerThis value is 2800 ~ 3200kg/m fand slag ball density, not ceramic fiber density

- Q: Definition of ceramic fiber

- The utility model has the advantages of light weight, high temperature resistance, small heat capacity, good insulation and heat insulation performance, good high-temperature heat insulation performance, no toxicity, etc..So far, Chinese domestic ceramic fiber manufacturers now have a total of more than 200 large and small, but the temperature is 1425 DEG C (zirconium containing fiber) production process and the following ceramic fibers, were divided into left and blowing two carpet carpet.

- Q: What is the process of producing ceramic fiber mats?

- Specifications:Diameter 10mm-- infinityProduct features:1) the continuous use temperature can reach 1000 DEG C, and the service temperature can reach 1260 DEG C for a short time.2) has good acid and alkali corrosion resistance and aluminum, zinc and other molten metal melting ability.

- Q: What is ceramic fiber?

- 1, ceramic fiber is a fibrous lightweight refractory material, has the advantages of light weight, high temperature resistance, good thermal stability, low thermal conductivity, specific heat and resistance to mechanical vibration, and thus in machinery, metallurgy, petroleum, ceramics, glass, electronics and other industries have been widely used.2, ceramic fiber products is a good refractory. The utility model has the advantages of light weight, high temperature resistance, small heat capacity, good insulation and heat insulation performance, good high-temperature heat insulation performance, no toxicity, etc..3, light quality, good heat insulation performance, good thermal stability, good chemical stability, easy processing and convenient construction. It is neither wear-resistant nor collision resistant, can not resist the erosion of high-speed airflow, and can not resist the erosion of molten slag.

- Q: What is ceramic fiber paper?

- The use of ceramic fiber paper, at 300 degrees Celsius (about) gradually ablate.

- Q: What kind of material is ceramic fiber? What are the basic performance?

- Ceramic fiber, referred to as "ceramic fiber felt", is a kind of high temperature resistant refractory material (such as precious stones) by arc melting, compressed air sprayed with a fibrous material, also known as "ceramic fiber cotton.". Using ceramic fiber cotton, it can be made into all kinds of ceramic fiber products. The content of domestic ceramic fiber felt from AI2O3 is 62% and 45%, the former is 1150-2000 DEG C, and the latter is l000 DEG C.The ceramic fiber felt by the adhesive is divided into hard ceramic fiber felt (aluminum phosphate adhesive), ceramic fiber felt soft (adhesive latex, polymerization aluminum, water glass, methyl cellulose, latex 11 aluminum phosphate composite adhesive) and ceramic fiber wet felt (adhesive silica sol) three. According to the performance of the felt and the temperature of the furnace, the hot surface of the furnace wall can be made of hard felt.The size of the ceramic fiber product is 600 * 400 * 20 (10) mmThe basic properties of the felt are as follows:(L) the use of high temperature can reach l000 degrees centigrade.

- Q: Refractory ceramics and other refractory materials manufacturing is a big industry?

- For example: petrochemical, steel, fertilizer, casting, glass, cement and other industries.

- Q: What brand of ceramic fiber products is best?

- Ceramic fiber, ceramic fiber, aluminum silicate fiber, its variety of products, the main products include ceramic fiber blanket (aluminum silicate blanket), ceramic fiber module (aluminum silicate module), ceramic fiber board (aluminum silicate), ceramic fiber paper (paper / aluminum silicate refractory fibre paper), ceramics (aluminum silicate fiber felt mat), ceramic fiber, ceramic fiber, ceramic fiber rope etc..The quality of the above products can be highlighted from two aspects:1, large-scale production2, the application of advanced technology3, brand awareness of the high and low

- Q: ceramic fiber

- Advantages of ceramic fiberRefractory ceramic fiber material is a lightweight and efficient thermal insulation material. It has the following advantages over traditional heat insulation materials:Ceramic fiber as lining, low volume density: ceramic fiber lining than light heat insulation brick lining light more than 75%, lighter than light castable lining light 90% to 95%. If using fiber lining, it can greatly reduce the steel structure load and prolong the service life of the furnace.The heat capacity (heat storage capacity) of ceramic fiber lining is low: the heat capacity of ceramic fiber is only about l/10 of light heat resistant lining and light castable lining, and the heat capacity of lining material is proportional to the weight of lining. Low heat capacity means the furnace in the reciprocating operation absorb less heat and heating speed, greatly reducing the operational control of the temperature in energy consumption, especially for heating furnace and furnace, furnace shutdown has obvious energy saving effect.Ceramic fiber lining: low thermal conductivity of ceramic fiber lining in the average temperature of 400 degrees, the thermal conductivity is less than 0.1w/mk, the average 600 degrees less than 0.l5 w/mk, average 1000 degrees less than 0.25w/mk, about l/8 as a lightweight clay brick, lightweight refractory lining l/10, adiabatic effect.The construction of ceramic fiber lining is simple: no expansion joints are needed during construction, and the construction personnel can be started after the basic training. The technical factors of construction have little influence on the insulation effect of the lining. Ji'nan Sheng Yang

- Q: How to choose the right ceramic fiber and aluminum silicate products?

- 3, according to the thickness of insulation to chooseThere are a lot of insulation thickness of furnace is fixed, the insulation thickness of conventional material is inappropriate, only according to the heat flow calculation formula to calculate the appropriate level of insulation material is the most scientific, the conventional case raised to two of the product can be registered.

Send your message to us

customer-tailor ceramic fiber board used for water heater

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords