1.2080 Cold Work Die Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.2080 Cold Work Die Steel Round Bar

Specifications

1. 2080

1. cold work mould/die steel

2. High carbon high chromium type ledeburite

3. High hardness wear resistance

Product description

1. Cr12 steel is a widely used cold work die steel, a type of high carbon high chromium ledeburite . The steel has good hardenability and good abrasion resistance

2. Mainly used to with stand the impact load is smaller, and require high abrasion resistance Die and punch, cold-cut scissors, drill sets, gauges, drawing die, pressure die thread rolling board, drawing die thread rolling die.

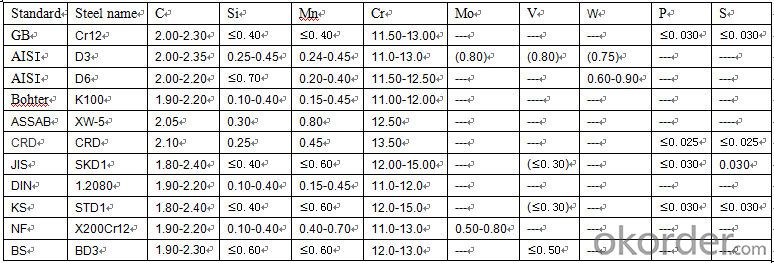

Chemical composition(for reference only)

Delivery of hardness and quenching hardness

Steel name | Delivery status | Quenched specimens | |||

Hardness HBW | Impressiondiameter (mm) | Quenching temperature/°C | Cooling medium | hardness ≥HRC | |

Cr12 | 269~217 | 3.7~4.1 | 950~1000 | oil | 60 |

Physical properties

Cr12 critical temperature

Critical point | Ac1 | Acm | Ar1 | Arcm | Ms |

temperature(approximation)/°C | 810 | 835 | 755 | 770 | 180 |

Cr12 Hot Working Technology

Item | Heating temperature/°C | start forging temperature/°C | final forging temperature/°C | type of cooling |

Steel ingot | 1140~1160 | 1100~1120 | 900~920 | Slow cooling |

Steel billet | 1120~1140 | 1080~1100 | 880~920 | Slow cooling |

Cr12 heat treatment

between the quenching temperature and the hardness of the relationship

quenching temperature/°C | 875 | 900 | 925 | 950 | 975 | 1000 | 1050 | 1100 |

Hardness HRC | 54.5 | 57 | 60 | 62.5 | 65 | 66 | 64 | 59.5 |

Delivery status: steel delivered in the annealed condition

We are professional manufacture of tool steel. We can provide various kinds of tool steel and mould steel. If you have any question regarding our products ,please feel free to let us know. We assure you will receive our best attention to your enquiry.

Products

- Q: What are the typical hardness values for different grades of steel round bars?

- The hardness values for different grades of steel round bars can vary depending on the specific grade and the manufacturing process used. However, there are some typical hardness values that can be used as a general guideline. For low carbon or mild steel round bars, the typical hardness values range from about 120 to 250 Brinell Hardness (HB). These grades of steel are known for their relatively low strength and hardness but can be easily machined and welded. Medium carbon steel round bars, commonly used in applications that require higher strength and hardness, typically have hardness values ranging from about 200 to 400 HB. These grades of steel are often used in construction, automotive, and machinery industries. High carbon or alloy steel round bars, which offer even greater strength and hardness, can have hardness values ranging from 400 to 700 HB or even higher. These grades of steel are commonly used in applications that require high wear resistance, such as cutting tools, gears, and bearings. It is important to note that these hardness values are approximate and can vary depending on factors such as heat treatment, alloy composition, and the specific manufacturing process employed. Therefore, it is always recommended to consult the manufacturer's specifications or conduct hardness testing to determine the exact hardness values for a specific grade of steel round bar.

- Q: What are the advantages of using nickel-chromium-titanium alloy steel round bars?

- Some advantages of using nickel-chromium-titanium alloy steel round bars include their high strength and durability, excellent corrosion resistance, and good heat resistance. These alloy steel round bars also offer superior wear resistance and can withstand harsh environments. Additionally, they have good machinability, making them suitable for various applications in industries such as aerospace, automotive, and oil and gas.

- Q: What are the different types of steel round bars used in the defense industry?

- In the defense industry, various steel round bars are commonly employed due to their strength, durability, and ability to withstand harsh conditions. Some of the frequently utilized types are as follows: 1. High-strength low-alloy (HSLA) steel round bars: These bars possess a high strength-to-weight ratio, making them ideal for applications where weight reduction is crucial. They find extensive use in the construction of armored vehicles, tanks, and other military equipment. 2. Stainless steel round bars: Stainless steel exhibits remarkable resistance to corrosion and rust, making it an excellent choice for defense applications exposed to moisture or harsh environments. Its wide usage includes the manufacturing of military aircraft, naval vessels, and firearms. 3. Carbon steel round bars: Carbon steel is a versatile and cost-effective material extensively used in the defense industry. It offers excellent strength and hardness, making it suitable for various applications, such as missile components, gun barrels, and armor plates. 4. Alloy steel round bars: Alloy steel is a blend of different metals, typically including chromium, molybdenum, and nickel, which enhances its mechanical properties. It finds common application in the production of military-grade vehicles, artillery systems, and munitions. 5. Tool steel round bars: Tool steel is specifically designed to possess exceptional hardness, wear resistance, and toughness. It is often employed in the manufacturing of cutting tools, drills, and other equipment utilized in the defense industry. Each type of steel round bar possesses unique properties and advantages, enabling it to meet specific requirements within the defense sector. The selection of the appropriate steel round bar depends on the specific application and the desired performance characteristics needed to meet the demands of the defense industry.

- Q: What is the maximum copper content allowed for steel round bars?

- The maximum copper content allowed for steel round bars typically depends on the specific industry standards and specifications. However, in general, the copper content in steel round bars is usually limited to around 0.35% to 0.50% to maintain the desired mechanical properties and prevent any negative effects on the material's performance.

- Q: What are the different types of steel round bars used in the manufacturing of shafts?

- When manufacturing shafts, various types of steel round bars are commonly used. The selection of the steel round bar depends on the specific application and requirements of the shaft. Here are some of the frequently utilized types: 1. Carbon Steel Round Bars: These round bars are the most commonly used in shaft manufacturing. Carbon steel provides good strength and toughness, making it suitable for a range of shaft applications. 2. Alloy Steel Round Bars: By adding elements like chromium, nickel, or molybdenum to carbon steel, alloy steel round bars are created. This enhances the strength, hardness, and wear resistance of the shaft, making it appropriate for demanding applications. 3. Stainless Steel Round Bars: Stainless steel is highly resistant to corrosion and offers excellent mechanical properties. It is commonly used in shafts that require resistance to corrosion, high temperatures, or harsh environments. 4. Tool Steel Round Bars: Tool steel round bars are renowned for their exceptional hardness, toughness, and wear resistance. They are used in shafts for cutting tools, molds, and dies that necessitate high performance and durability. 5. High-Speed Steel Round Bars: Primarily used in shafts for cutting tools such as drills, mills, and taps, high-speed steel round bars possess excellent heat resistance and can withstand high cutting speeds without losing their hardness. 6. Mild Steel Round Bars: Mild steel round bars are low carbon steel bars that offer good weldability and machinability. They are commonly used in shafts for less demanding applications that do not require high strength or hardness. Considering the specific requirements, such as strength, hardness, corrosion resistance, and temperature resistance, is crucial when choosing the appropriate type of steel round bar for manufacturing shafts.

- Q: How do you prevent steel round bars from rusting?

- To prevent steel round bars from rusting, several measures can be taken. One effective method is to apply a protective coating or paint to the surface of the bars, which acts as a barrier against moisture and oxygen. Additionally, regular cleaning and maintenance to remove any dirt, debris, or corrosive substances can help prevent rust formation. Storing the bars in a dry and controlled environment, away from humidity and moisture, is also crucial. Moreover, using galvanized steel round bars, which have a zinc coating, or stainless steel bars that are resistant to corrosion, can provide long-term rust prevention.

- Q: What are the advantages of using nickel-titanium alloy steel round bars?

- Nickel-titanium (NiTi) alloy steel round bars offer several benefits. Firstly, they possess exceptional shape memory and superelasticity properties. This means that they can be bent or deformed and then return to their original shape when heated or when stress is removed. This unique characteristic makes them perfect for applications requiring flexibility and resilience, such as surgical instruments or orthodontic wires in the medical field. Another advantage of NiTi alloy steel round bars is their high resistance to corrosion. Both nickel and titanium are highly resistant to corrosion, making the alloy extremely durable and long-lasting. This makes them suitable for industrial applications, including marine environments where exposure to moisture and saltwater can cause corrosion in other metals. Additionally, NiTi alloy steel round bars have a high strength-to-weight ratio. Despite being lightweight, they possess excellent mechanical properties, including high tensile strength and good fatigue resistance. This makes them suitable for engineering and structural applications in industries like aerospace, automotive, and construction. The bars' lightweight nature also allows for easier handling and transportation. Moreover, NiTi alloy steel round bars demonstrate excellent thermal stability, with a wide temperature range of usability. They can withstand extreme temperatures without losing their shape memory or superelasticity properties. This makes them suitable for applications involving exposure to high or low temperatures, such as in the aerospace or oil and gas industries. To sum up, the benefits of using NiTi alloy steel round bars include their shape memory and superelasticity properties, high resistance to corrosion, high strength-to-weight ratio, and excellent thermal stability. These qualities make them a versatile and reliable choice for a wide range of applications in various industries.

- Q: What are the advantages of using niobium-alloy steel round bars?

- There are several advantages to using niobium-alloy steel round bars. Firstly, niobium-alloy steel has excellent strength and toughness properties. The addition of niobium to the steel increases its strength while maintaining its ductility, making it ideal for applications that require high strength and durability. This allows niobium-alloy steel round bars to withstand heavy loads and shocks without deforming or breaking easily. Secondly, niobium-alloy steel has a high resistance to corrosion. This makes it suitable for use in harsh environments where exposure to moisture, chemicals, or corrosive substances is common. The corrosion resistance of niobium-alloy steel ensures that the round bars will remain intact and retain their structural integrity over time, reducing the need for frequent replacements and maintenance. Additionally, niobium-alloy steel has excellent weldability and formability. It can be easily welded and fabricated into various shapes and sizes, making it adaptable to different manufacturing processes and applications. This versatility allows for the production of custom-designed round bars that meet specific project requirements. Moreover, niobium-alloy steel has good heat resistance properties. It can withstand high temperatures without losing its strength or undergoing significant changes in its mechanical properties. This makes it suitable for applications that involve exposure to extreme heat or thermal cycling, such as in the aerospace or automotive industries. Furthermore, niobium-alloy steel is known for its excellent fatigue resistance. It has a high endurance limit, which means it can withstand repeated loading and unloading cycles without experiencing fatigue failure. This makes niobium-alloy steel round bars ideal for applications that involve dynamic or cyclic loading, such as in structural components or machinery. In conclusion, the advantages of using niobium-alloy steel round bars include high strength, corrosion resistance, weldability, formability, heat resistance, and fatigue resistance. These properties make niobium-alloy steel a reliable and cost-effective choice for various industries and applications.

- Q: Can steel round bars be used in manufacturing equipment?

- Steel round bars find extensive usage in the manufacturing industry, owing to their diverse advantageous properties. Renowned for their exceptional strength, durability, and resistance to wear and tear, these bars prove to be an ideal choice for heavy-duty machinery and equipment. They play a crucial role in the production of vital components such as shafts, axles, pins, and gears, which are indispensable for the smooth operation of machinery. Moreover, steel round bars possess the ability to be effortlessly machined, welded, and molded into various shapes, thus showcasing their versatility in different manufacturing applications. Consequently, steel round bars emerge as a dependable and extensively utilized material in the manufacturing industry for equipment construction.

- Q: How are steel round bars used in the construction of bridges and buildings?

- Due to their strength, durability, and versatility, steel round bars find wide usage in the construction of bridges and buildings. Typically made of carbon steel and possessing a circular cross-section, these bars are ideal for structural applications. In bridge construction, steel round bars are commonly employed to reinforce concrete structures. They are frequently embedded within concrete beams, columns, and slabs to enhance their load-bearing capacity and resist bending and shearing forces. Strategically placed in the concrete, these bars provide tensile strength to complement the compressive strength of the concrete. This reinforcement ensures that the bridge can endure heavy loads and traffic while maintaining its structural integrity. Similarly, in building construction, steel round bars play a crucial role in reinforcing concrete structures. They are commonly utilized in the construction of columns, beams, and foundations to increase their load-carrying capacity and prevent structural failure. During the pouring process, the bars are typically added to the concrete, forming a sturdy framework that enhances the building's strength and stability. Furthermore, steel round bars are utilized to create steel frames in building construction. These frames provide the skeletal structure of the building, supporting the weight of the floors, walls, and roofs. Due to their high strength-to-weight ratio, steel round bars are perfect for constructing lightweight yet robust frames that can withstand various loads, including wind and seismic forces. Additionally, steel round bars serve other purposes in construction, such as fabricating steel reinforcements, connectors, and fasteners. They can be welded, bolted, or threaded to join different structural elements, ensuring a secure and sturdy construction. Overall, steel round bars are an essential component in the construction of bridges and buildings, providing the necessary strength, durability, and flexibility to create structurally sound and long-lasting structures.

Send your message to us

1.2080 Cold Work Die Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches