Cold Drawn Die Steel,Tool Steel Bar 1.2510

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Cold Drawn Die Steel,Tool Steel Bar 1.2510

Product information:

1.Cold working die steel.

2.Wiht highest hardness and abrasion resistance in the Cr12 and 9SiCr.

3.Low impact toughness,should avoid tempering at about 300°c.

4.should do the resonable structure .

| Shape | Round | Diameter: 10mm~700mm |

| Flat | Thickness: 20mm-400mm | |

| Width: 60mm-600mm | ||

| Heat treatment | Normalized ; Annealed ; Quenched ; tempered | |

| Surface Condition | Black surface ; Grinded ; Machined | |

| Delivery Condition | hot rolled ; cold drawn ; forged | |

| Payment Terms | T/T; L/C | |

| Trade Terms | FOB; CIF | |

| Application | cold work die steel; hot work die steel; plastic die steel | |

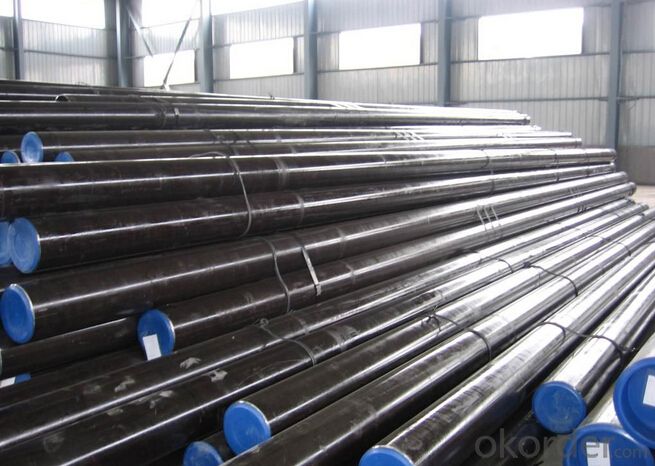

Product show:

Workshop show:

Our service:

-High manufacturing accuracy

-High strength

-Small inertia resistance

-Strong heat dissipation ability

-Good visual effect

-Reasonable price

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer's trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

If you need the sample, please feel free to let me know. Any question, we will contact you ASAP!

- Q: What are the different methods of surface peening for special steel?

- Surface peening is a process used to improve the mechanical properties of special steels by inducing compressive stresses on the surface. This technique helps to enhance the fatigue life, resistance to stress corrosion cracking, and overall durability of the material. There are several methods of surface peening that can be employed on special steel, including: 1. Shot Peening: This method involves bombarding the surface of the steel with high-velocity spherical particles, known as shot. The impact of the shot particles creates plastic deformation and induces compressive stresses on the surface. Shot peening is widely used due to its effectiveness in improving fatigue life. 2. Ultrasonic Peening: Ultrasonic peening utilizes high-frequency vibrations to induce compressive stresses on the surface of the steel. The vibrations are applied through a tool that is in contact with the surface, causing plastic deformation and the generation of compressive stresses. 3. Laser Peening: In laser peening, a high-energy laser beam is used to create shockwaves on the surface of the steel. These shockwaves induce plastic deformation and generate compressive stresses. Laser peening is known for its precision and ability to target specific areas of the material. 4. Cavitation Peening: This method involves creating cavitation bubbles in a liquid medium near the surface of the steel. The collapse of these bubbles generates high-intensity shockwaves that induce compressive stresses on the surface. Cavitation peening is particularly useful for irregularly shaped components. 5. Needle Peening: Needle peening is a technique where a bundle of fine needles is repeatedly impacted on the surface of the steel. This process induces plastic deformation and generates compressive stresses. Needle peening is commonly used for localized treatment of small areas. Each of these methods has its advantages and is suitable for specific applications. The selection of the surface peening method depends on factors such as the type of special steel, component geometry, desired improvements, and available equipment. It is important to consider the specific requirements and consult with experts to determine the most appropriate method for surface peening special steel.

- Q: What are the different methods for improving the creep resistance of special steel?

- There are several methods for improving the creep resistance of special steel. One approach is through alloying, where elements such as chromium, molybdenum, and tungsten are added to enhance the strength and stability of the steel at high temperatures. Another method is by heat treatment, which involves controlled heating and cooling processes to optimize the microstructure of the steel and improve its creep resistance. Additionally, surface treatments like carburizing or nitriding can be applied to increase the hardness and wear resistance of the steel, thereby improving its creep resistance. Lastly, proper design and engineering considerations, such as using thicker sections or incorporating reinforcements, can also contribute to enhancing the creep resistance of special steel.

- Q: What are the different grades of special steel?

- Special steel is classified into various grades based on its chemical composition, physical properties, and intended use. Some common grades include tool steel, stainless steel, alloy steel, and high-speed steel. These grades offer unique characteristics and are utilized in different industries such as manufacturing, construction, automotive, and aerospace.

- Q: What are the main corrosion resistance properties of special steel?

- The main corrosion resistance properties of special steel include high resistance to rust, oxidation, and corrosion in various environments, such as acidic, alkaline, and marine conditions. Special steel is often alloyed with elements like chromium, nickel, and molybdenum, which form a protective layer on the surface and enhance its resistance to corrosion. Additionally, special steel may have a low carbon content, reducing the likelihood of corrosion caused by carbide precipitation. These properties make special steel a reliable choice for applications where resistance to corrosion is crucial, such as in the construction, automotive, and aerospace industries.

- Q: Can special steel be used in the power generation equipment manufacturing industry?

- Yes, special steel can be used in the power generation equipment manufacturing industry. Special steel, also known as alloy steel, offers enhanced properties such as high strength, corrosion resistance, and heat resistance. These qualities make it suitable for various components in power generation equipment, including turbines, boilers, and generators, which often operate under extreme conditions. By using special steel, manufacturers can ensure the durability, efficiency, and reliability of the equipment, thus meeting the demanding requirements of the power generation industry.

- Q: What are the common challenges in forging special steel?

- Forging special steel poses several common challenges that manufacturers and engineers must address in order to achieve desired outcomes. One of the primary challenges in forging special steel is maintaining precise temperature control throughout the process. Special steels often have specific heat treatment requirements, and any deviation from the recommended temperature range can adversely affect the final properties of the material. Achieving and sustaining the right temperature is crucial to ensure desired mechanical properties like strength, hardness, and toughness. Another challenge in forging special steel is controlling the cooling rate during quenching. Quenching is a critical step in the heat treatment process that helps to achieve the desired hardness and strength in special steels. However, rapid cooling can lead to the formation of undesirable microstructures or even cracking. Therefore, carefully managing the cooling rate is essential to avoid these issues and ensure optimal material properties. Additionally, shaping special steels through forging can be challenging due to their high strength and hardness. These materials are often more difficult to deform compared to regular steels, requiring higher forging pressures and specialized equipment. The resistance to deformation can lead to increased wear on the forging dies, requiring frequent maintenance and replacement. Furthermore, special steels may contain alloying elements that can affect their forgeability. Some alloying elements can promote grain growth, which can reduce the mechanical properties of the material. Finding the right balance of alloying elements and optimizing the forging process parameters is crucial to achieve the desired microstructure and properties in the final product. Lastly, ensuring consistency and repeatability in the forging process can be a challenge. Special steels are often produced in smaller quantities or for specific applications, making it important to maintain process control and quality assurance. Proper documentation, monitoring, and quality control measures need to be implemented to ensure that the forged special steel meets the desired specifications and performance requirements. Overall, forging special steel requires careful attention to temperature control, cooling rate during quenching, shaping difficulties, alloying elements, and maintaining consistency. Addressing these challenges through proper process control and optimization is crucial to obtain high-quality special steel products with the desired mechanical properties and performance characteristics.

- Q: What are the main applications of special steel in the medical field?

- Special steel is widely used in the medical field for various applications. Some of the main applications include surgical instruments, implants, and medical devices. Surgical instruments such as forceps, scalpels, and scissors are often made from special steel due to its high strength, durability, and corrosion resistance. Implants, such as joint replacements and dental implants, are commonly made from special steel alloys that provide strength, biocompatibility, and resistance to wear and tear. Additionally, special steel is used in the production of medical devices like needles, catheters, and stents, where its properties contribute to their effectiveness and safety.

- Q: What are the properties of low-alloy steel?

- Low-alloy steel possesses several properties that distinguish it from other types of steel. Firstly, it contains a lower percentage of alloying elements compared to other alloy steels. This leads to a reduction in the overall cost and increases the weldability and formability of the steel. Additionally, low-alloy steel exhibits improved strength and toughness, making it suitable for applications requiring high structural integrity. It also offers resistance to corrosion and abrasion, enhancing its durability and longevity. Furthermore, low-alloy steel can be heat-treated to further enhance its mechanical properties, such as hardness and ductility.

- Q: What are the applications of special steel in the aerospace industry?

- Special steel has various applications in the aerospace industry due to its exceptional properties. It is commonly used in aircraft engines, landing gears, and structural components. Special steel's high strength-to-weight ratio, corrosion resistance, and ability to withstand high temperatures make it suitable for critical parts that require durability, reliability, and performance in extreme conditions. Additionally, its excellent fatigue resistance and ability to be heat-treated allow for the production of lightweight yet robust components, contributing to fuel efficiency and overall aircraft performance.

- Q: What are the properties of copper alloys?

- Copper alloys have various properties such as high electrical and thermal conductivity, excellent corrosion resistance, good strength and ductility, as well as a pleasing aesthetic appearance. They are also known for their antimicrobial properties and are commonly used in electrical wiring, plumbing systems, and various industrial applications.

Send your message to us

Cold Drawn Die Steel,Tool Steel Bar 1.2510

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords