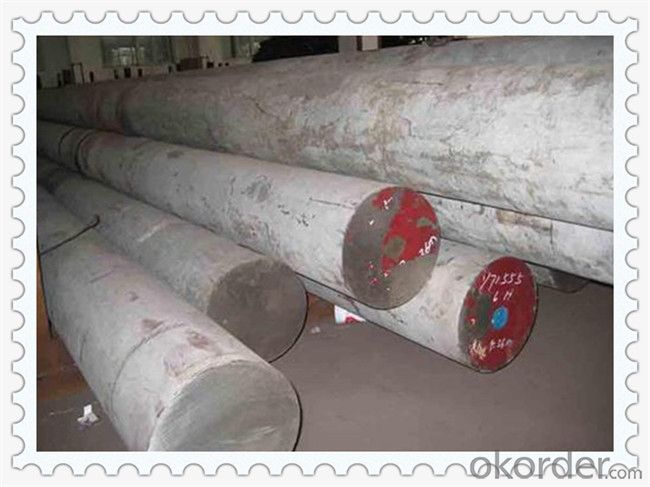

1.2344 / SKD61 Hot Work Die Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.2344 / SKD61Hot Work Die Steel Round Bar

Comparative standards: | |||||||||||||

AISI/ASTM H13,X40CrMoV5-1, DIN 1.2344, JIS SKD61, BS BH13, NFA Z40CDV5 | |||||||||||||

Product Descriptions: | |||||||||||||

Chemical Composition(%) | |||||||||||||

C | Si | Mn | Cr | S | P | Mo | V | ||||||

0.32-0.45 | 0.80-1.25 | 0.20-0.60 | 4.75-5.50 | ≤0.02 | ≤0.03 | 1.10-1.75 | 0.80-1.20 | ||||||

Dimesions | |||||||||||||

Flat Bar | |||||||||||||

Cold Work Tool Steel | Thickness: 20~450mm;Width:200~600mm | Length:2000~6000mm | |||||||||||

Hot Work Tool Steel | Thickness: 20~650mm;Width:200~1200mm | ||||||||||||

Plastic Mold Steel | Thickness: 20~600mm;Width:200~1200mm | ||||||||||||

Round Bar | |||||||||||||

Cold Work Tool Steel | Dia:20~600mm | Length:2000~6000mm | |||||||||||

Hot Work Tool Steel | Dia:20~650mm | ||||||||||||

Plastic Mold Steel | Dia:20~650mm | ||||||||||||

Dimensions can be customized | |||||||||||||

Heat Treatment | |||||||||||||

Hardness | 60-64HRC | - | |||||||||||

Anneal | 840-860°C | ≤207-255HB | |||||||||||

Quenching | 980-1040°C | Air or oil cooling | |||||||||||

Tempering | 510-540°C | 60-64HRC, tempering twice | |||||||||||

- It is annealed before ex-factory, which ensure good metallographic structure, proper hardness and good workability. There is no need to anneal again. - But It must be re-annealed if reforged, as the original organization and performance are destroyed after reforged, and the forging stress increased. - Normally it will be annealed twice and the temperature of the second annealed is 20°C lower than the first one. | |||||||||||||

- Q: Can steel round bars be used in the manufacturing of office furniture?

- Office furniture can indeed utilize steel round bars. Steel, being a versatile and enduring material, can be molded into various shapes, including round bars. These bars are useful as structural elements in office furniture, such as table legs, chair frames, and support beams. They provide the furniture with strength and steadiness, making them suitable for heavy usage in office settings. Furthermore, steel can be finished in diverse manners, such as powder coating or chrome plating, to enhance its appearance and match the office space's aesthetic. All in all, the utilization of steel round bars in the production of office furniture offers both durability and stability, while also providing a contemporary appearance.

- Q: Are the bolts for the round bar or round steel?

- The utility model relates to a pair of bolts which are used for drawing between the inner and the outer formwork of the wall when the beam and the column template are set. The bolt under concrete lateral pressure and other loads, ensure the spacing inside and outside the template can meet the design requirements, but also the template and its support structure fulcrum, so the impact on the overall arrangement of bolt, the template structure stiffness and strength greatly.

- Q: Are steel round bars prone to deformation?

- Yes, steel round bars can be prone to deformation under certain conditions. Factors such as excessive heat, extreme pressure, or improper handling can cause steel round bars to bend, warp, or twist. However, when manufactured and used properly, steel round bars are highly durable and resistant to deformation.

- Q: Can steel round bars be used in the energy industry?

- Steel round bars are indeed applicable in the energy industry. These bars are widely utilized in numerous energy industry applications owing to their exceptional attributes, including high strength, durability, and corrosion resistance. They find extensive use in the construction of power plants, oil rigs, pipelines, and other energy infrastructure projects. Moreover, machinery and equipment employed in the energy industry, such as turbines, generators, and pumps, are also manufactured using steel round bars. Furthermore, renewable energy technologies, including wind turbines and solar power systems, often incorporate steel round bars. In summary, steel round bars offer versatility and reliability, making them a superb choice for meeting the demanding requirements of the energy industry.

- Q: What is the maximum vanadium content allowed for steel round bars?

- The maximum vanadium content allowed for steel round bars varies depending on the specific steel grade and industry standards. However, in general, the maximum vanadium content is typically around 0.10-0.15%.

- Q: What is the difference between carbon steel and alloy steel round bars?

- Both carbon steel and alloy steel round bars find extensive use across various industries, although they vary in terms of their composition and properties. In particular, carbon steel round bars consist predominantly of iron and carbon, with small amounts of other elements present. Depending on the grade, the carbon content typically ranges between 0.05% and 2.0%. These bars are renowned for their robustness and hardness, rendering them suitable for applications demanding high durability and resistance to wear. Additionally, carbon steel round bars possess excellent machinability, allowing them to be easily shaped and molded into desired forms. Nevertheless, they may exhibit limited resistance to corrosion, necessitating the application of additional protective coatings in corrosive environments. In contrast, alloy steel round bars are produced by incorporating various alloying elements into carbon steel. Such elements encompass manganese, chromium, nickel, molybdenum, and others. The inclusion of these elements augments the properties of the steel, including enhanced strength, toughness, and resistance to wear and corrosion. Alloy steel round bars are frequently selected for applications demanding specific characteristics, such as resistance to high temperatures, a high strength-to-weight ratio, or improved machinability. In conclusion, the primary disparity between carbon steel and alloy steel round bars lies in their composition and resulting properties. Carbon steel round bars primarily consist of iron and carbon, offering commendable strength and hardness; however, they may exhibit limited resistance to corrosion. Conversely, alloy steel round bars incorporate supplementary alloying elements, bolstering specific properties like increased strength, toughness, and corrosion resistance. The selection between carbon steel and alloy steel round bars hinges upon the precise requirements of the application at hand.

- Q: Can steel round bars be used for making propeller shafts?

- Yes, steel round bars can be used for making propeller shafts. Steel is a commonly used material for propeller shafts due to its strength, durability, and resistance to corrosion. Round bars, in particular, are often chosen for their shape, which provides optimal strength and load-bearing capabilities. The selection of steel grade and specific properties will depend on the requirements of the propeller shaft, such as the desired length, diameter, and torque capacity. Additionally, other factors like cost, weight, and manufacturability may also influence the choice of steel round bars for propeller shafts.

- Q: How is a steel round bar made?

- To create a steel round bar, a series of steps must be taken during the manufacturing process. First, high-quality raw materials, typically steel billets, are carefully chosen. These billets are then heated in a furnace until they reach an appropriate temperature for forging. Once the billet has been heated, it is placed into a forging machine. Here, it undergoes significant pressure, either from repeated hammer strikes or mechanical press application, to shape it into a round bar. The goal of this forging process is to achieve the desired shape and dimensions. Following the forging stage, the round bar enters a heat treatment process. This involves heating the bar to a specific temperature and then rapidly or slowly cooling it. This treatment enhances the bar's mechanical properties, including its strength, hardness, and toughness, making it suitable for various applications. After heat treatment, the bar goes through machining. This step involves cutting, turning, and grinding the bar to achieve the desired dimensions and surface finish. By doing so, the bar meets the required tolerances and specifications. Lastly, the round bar undergoes a final inspection to ensure its quality and adherence to specified standards. This inspection involves checking its dimensions, surface finish, and any other specific requirements, such as chemical composition or mechanical properties. In conclusion, the production of a steel round bar involves carefully selecting raw materials, forging, heat treatment, machining, and final inspection. Each step in this process is essential in guaranteeing the quality and integrity of the end product.

- Q: How do you determine the straightness of a steel round bar?

- There are several methods available to determine the straightness of a steel round bar. One commonly used technique involves visually inspecting the bar for any visible bends, twists, or deviations from a straight line. This involves placing the bar on a flat surface and checking for gaps or unevenness between the bar and the surface. Another method involves utilizing a straightedge or precision ruler. By placing either of these tools along the length of the bar, any deviations from a straight line can be easily detected. This method allows for more precise measurements and can even identify slight bends or curves. Alternatively, measuring devices like dial indicators or laser alignment tools can be employed to assess the straightness of a steel round bar. These devices provide more accurate measurements and can quantify the degree of deviation from a straight line by providing numerical readings. It should be noted that the acceptable level of straightness may vary depending on the specific application or industry standards. In such cases, it may be necessary to adhere to specific tolerances or guidelines to ensure that the steel round bar meets the required straightness criteria. In conclusion, determining the straightness of a steel round bar necessitates careful visual inspection and the utilization of appropriate measuring tools to ensure that it satisfies the necessary straightness standards for its intended purpose.

- Q: Can steel round bars be hardened through heat treatment?

- Yes, steel round bars can be hardened through heat treatment. Heat treatment is a process that involves heating the steel to a specific temperature and then rapidly cooling it to achieve the desired hardness and strength. There are different heat treatment methods, such as quenching and tempering, which can be used to harden steel round bars. Quenching involves heating the steel to a critical temperature and then rapidly cooling it in a liquid medium, such as oil or water, to achieve maximum hardness. Tempering, on the other hand, involves reheating the quenched steel to a lower temperature to reduce brittleness and improve toughness while maintaining a desirable hardness level. Heat treatment can significantly improve the mechanical properties of steel round bars, making them suitable for various applications that require high strength and hardness.

Send your message to us

1.2344 / SKD61 Hot Work Die Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords