Soft Touch Lamination Film from A Professional Manufacturer

- Loading Port:

- Xiamen

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Soft Touch Lamination Film Description:

Soft Touch Lamination Film is coated on books and magazine; catalogs; pictures; promotional materials; non-drying adhesive; paper bag; clothes lag.Blueprint document; outdoor advertisement; spray painting; post; digital print.Wedding photograph; photo album.Outside coating for wrapping box for food; medicine; cosmetic; gift; liquor, ect.

Soft Touch Lamination Film is widely used in food,medicine,cosmetics and other industries packaging, can also be used for printing,garland,adhesive sticker ,gold and silver carboard

2.Main Features of the Soft Touch Lamination Film:

Low chormatic aberration after lamination.

Easy to use, saving operating time.

No bubble, wrinkle or desquamate.

Glossier than traditional laminating films, keep for a long time and protect the printing color from changing.

None solvent pollution, keep the factory much safer an environment-friendly, health for the workers.

Suitable for ordinary hot laminating machine.

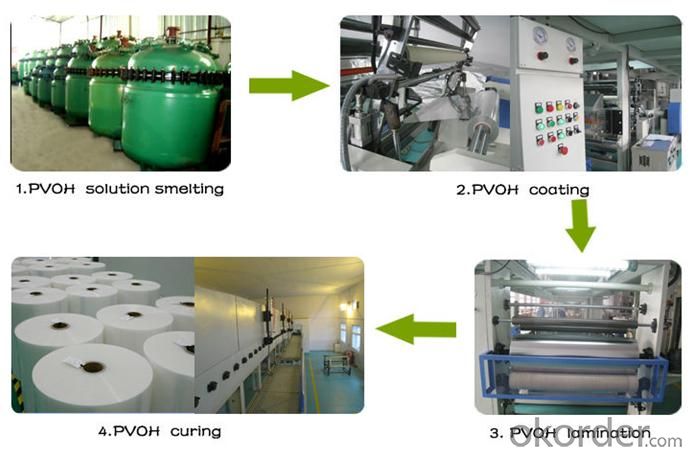

3. Soft Touch Lamination Film Images

4. Soft Touch Lamination Film Specification

Appearance ( color ) | : light white transparent liquid | |

2 | Solid content(NV%) | : 6.3±0.2% |

3 | Viscosity | :27s±2s |

4 | Diluent | : water |

washing solvent | ||

5 | Coating solution temp. | : normal temperature |

6 | Storage condition | : 5~30°C |

7 | WVTR result | :NOT AVAILABLE |

8 | O2TR result | :≤75px3/m2•24h•0.1MPa |

9 | Compatibilityand good bond coating with polyurethane adhesive | Enough |

: polyesther or polyether adhesive | ||

10 | Appearance after coating | : ( must brightly or clearly |

11 | Bonding strength between PET and PVA | ………………………………gr/15mm or N/15mm |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

one of the largest thermal film manufactures in China. We are engaged in developing and producing new types of environmental friendly laminating materials(thermal laminating film for offset prints, digital prints and advertising inject prints).Our products are exported to Europe, North America, South America, South East Asia, etc.

②What is the package?

3 inch paper roll is always made with more than 1000 meters,so it is always packaging with one roll one carton.And 1 inch paper core is made with below 500meters,so we always packaging it with 9 rolls with one carton.and then by pallet.

③How to application manual?

.Adjust roller pressure and temperature according to different types of paper and ink.

.When using the film for the first time or changing to other sizes, we recommend a small trial volume before going into fully mass lamination.

.The following situation will affect the quality of the film during lamination.

a. When using metal ink

b. When the ink contains too much wax, dried oil, adhesive, and silicon additive. etc

c. When the ink is too thick

d. When the ink is not completely dry

e. When the paper contains too much moisture

f. When there is too much powder

- Q:What to do if there are some white dots on the protective film coated on high-light product?

- Please use protecive film of better quality. The foggy white dots may be generated because the glue reacts with the air.

- Q:What does it mean that a protective film is anti-blue-ray?

- Anti-blue-ray protective film can weaken the blue ray of the screen. It would not be so dazzling that it can ease visual fatigue. Blue ray is the light emitted LED screen. It's a component of artificial light. It's bad to the eyes looking at the screen for a long time.

- Q:The site is now waiting for acceptance, but the door on the layer of protective film to tear up a lot of trouble, one day only to tear two or three, now with a hair dryer blowing while tearing effect is not significant, this is the door looks like plastic doors, the speed for master pointing.

- Methods to remove the protective film on the door:The best way is a decoration immediately tear off.

- Q:Is it okay not to tear off the protective film on the mirror stainless steel during laser cutting? How about the effect?

- Before laser cutting, the stainless steel must be covered with specific protective film. Ordinary film may curl or cause bubbles or even twine around the cutter head.

- Q:How to remove the protective film on PCM plate in a quick way?

- PCM plate can be coated with film using machine. But you can only tear off the film by hands. There is no such machine that can remove the film for you.

- Q:Why is PET anti-static protective film developed so well?

- In the high-end electronic processing industry, in particular, to achieve direct machine hand film, much faster efficiency.

- Q:How to remove the protective film of stainless steel?

- Blow the film using electric hair drier and then tear it off.

- Q:Bank card protection film off, you can swipe card and withdraw money?

- Card flow:Prepare your old bank cards, cardholder ID cards, and cash from 5 to 20 yuan;To do the card or bank savings, take a number line;Until after the call, with prepared documents and money to counter;

- Q:How to remove the protective film on the door cover and window cover in a quick way?

- You can try to heat the film with electric hair drier and then tear it off.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Soft Touch Lamination Film from A Professional Manufacturer

- Loading Port:

- Xiamen

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords