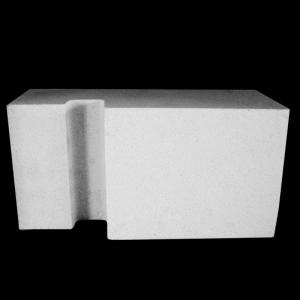

High Water Permeability Paving Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Paving brick, square brickGood resistance to acids, salts and oils.

Excellent abrasion resistance

High water permeability

Our paving brick, square brick has the following features.

1) Good resistance to acids, salts and oils;

2) Exellent abrasion resistance;

3) High water-permeable quality;

4) High strength, long life;

5) Various colors and pattens.

Specifications :

1) Color: red, yellow, brown, pink, maroon,green, black, chestnut, etc.

2) material: clay

3) L*W*H(mm)

200*100*40~60

230*230*40~50

230*114*40~60

100*100*40~60

400*100*40~60

Other size is available according to customer's request.

4) Packing: wooden pallet, plastic film wrapped around.

- Q:Acid resistant brick lining, engineering scaffolding, how to take?

- Material preparation: the anti-corrosion materials used in this project are stored in the appropriate warehouse (site), and the incoming materials are tested to comply with the requirements of the HGJ229-91 specification. Equipment preparation: cutting machine, mixer, grinder, trolley, cement plate, rope

- Q:What brand does acidproof ceramic tile ten big famous brands have?

- Now let's introduce in detail of acid resistant ceramic ten brand-name what brand, in fact the ten major brands of ceramic tile manufacturers have to choose acidproof tile, tile acid, these ten brands of ceramic tile manufacturers to be sure, but the ten tile brand ranking of two, you can go to compare, look at the two ten famous brand rankings have what different tiles.

- Q:The difference between polished tiles and glazed tiles?

- The brick is a brick block pattern, glazed tile surface is a layer of glaze, the following are the embryo is yellow brick, looks like that, for a long time, this layer of glaze will slowly worn away

- Q:Which acid proof tile factory is reliable in quality?

- Some of the plants in the market are directly drawn from the local ordinary clay and fired directly into tiles. They also impact the market at low prices, and the consequences can be imagined.

- Q:What is anticorrosive floor tile?

- According to the above requirements, the construction cost of a square is more expensive than the normal paving tiles;

- Q:Is it necessary to use sulphate resisting cement in alkaline areas?

- The sulfate resisting silica cement is divided into two categories: medium sulfate resistant Portland cement and high sulfate resistant Portland cement. A suitable cementitious material with resistance to moderate concentration of sulfate ion is prepared by adding proper amount of gypsum in the proper proportion of Portland cement clinker, which is called medium sulfate resisting portland cement. Middle sulfur resistant cement. Code P & MSR. A cementitious material with high resistance to sulfate ion corrosion is prepared by adding proper amount of gypsum into the clinker of proper proportion of Portland cement clinker, which is called high sulfate silica cement. High sulfur resistant cement.

- Q:What is acidproof ceramic tile?

- Acid resistant ceramic tiles are widely used in petroleum, chemical, pharmaceutical, food, dairy, juice, papermaking, chemical fertilizer, pesticide, chemical fiber, textile, metallurgy, power plants, electroplating industry and room, tower, tank, tank, tank anti-corrosion lining, and the sewage treatment project and open ground work site to play its resistance corrosion effect.

- Q:Construction method of acid proof brick

- QAGrassroots requirements: after the acceptance of the rubber lining, clean, keep clean and dry.Construction conditions: temperature at 15-30 Deg. C anti-corrosion construction is appropriate, the relative humidity is less than 80%, according to the temperature change adjust the dosage of curing agent, low temperature, humidity is too large, should be used to wet machine to adjust the temperature and humidity on the construction site.The construction of anticorrosive engineering is afraid of water and is afraid of drying.The preparation of mortar and glue is strictly carried out according to the proportion, and it is used up in the prescribed use time.

- Q:Acid proof brick, acid resistant porcelain in the paste process with no seam

- Acid resistant brick, acid resistant ceramic tile in the shop, many users only pay attention to beauty, and use not leave seam shop, or shop too tight, too close, easy to leave hidden dangers for the future.

- Q:The acid resistance is 99.4%. Is this acid resistant brick very bad?

- Do not recommend you buy the acid resistance of substandard tile, tile acid refers to the acid resistance of 99.8 according to the national standard

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Water Permeability Paving Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords