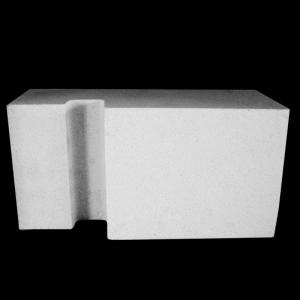

Acid Resistance Alumina Ceramic Lining Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Details: | standard export wooden case or pallet |

| Delivery Detail: | as per your order qantity |

Specifications

Acid proof bricks or acid resistance bricks

1. Many size

2. Good quality

3. Competitive price

4. Low cost

Product Description

Standard Acid proof Acid resistance Silica brick

The Acid Proof Brick / Acid resistance bricks have very excellent sulphuric acid proof performances. They can withstand violent heat and cold, and they are used in kinds of chemical acid conditions as walling , flooring and lining.

Features:

1) Ceramic acid-proof bricks and tiles:

a) Very excellent acid resistant and alkali resistant

b) High temperature resistance

c) Can withstand violent heat and cold

d) Used as flooring, lining in many kinds of chemical reactors, towers (including

drying towers and absorption towers), and tanks of acids and other chemicals in chemical factories, fertilizer factories, sulphuric acid factories and iron and steel factories

e) Also used as lining of antiseptic pools and ditches

2) Ceramic self-supporting domes:

a) Very excellent acid and alkali resistance

b) High temperature resistance

c) Widely used in for many chemical towers (such as sulfuric acid towers, drying towers and absorption towers) and many chemical reactors in chemical factories, fertilizer plants and sulphuric acid plants.

Main specification

Note: 1bricks and plate prlduce accorind to itcm 1.2.3of GB8488-87.

2can produce according to costomers product drawings .

3can design bricks , platc and gencral anti-acid cnginccring construction according to costoners tcchnical information . Bricks,plate main specification:

Packaging & Shipping

Packing: Standard export wooden case

Shipping: By vessel from any Chinese port

Our Services

1. Provide sample for test before order

2. Arrange production on time

3. Control quality and production time

4. Provide finished products and packing photots

5. Delivery on time and provide original documents

6. After sale service

7. Continous competitive price

- Q:Acid resistant brick lining, engineering scaffolding, how to take?

- Construction preparation, familiar with drawings, specifications, technical disclosure, do a good job of the handover process.

- Q:Cleaning metal surface rust stain, is it better to weld sulphuric acid or nitric acid?

- Acid etching is a chemical cleaning process to remove metal oxide and other impurities from the acid aqueous solution. As the acid and corrosion are more economical and suitable for continuous operation, it is the most effective way to remove the oxide surface of metal surface of large tonnage products. Especially cleaning iron and steel products, such as billets, ingots, steel plates, steel strips, wires, pipes and so on. Can also be used for steel forgings, casting cleaning, rust removal

- Q:The difference between polished tiles and glazed tiles?

- The brick is a brick block pattern, glazed tile surface is a layer of glaze, the following are the embryo is yellow brick, looks like that, for a long time, this layer of glaze will slowly worn away

- Q:How can acid proof cement be used?

- In the use of acid resistant cement, it is necessary to add hardener sodium fluosilicate, it will be mixed with acid resistant cement evenly; preferably 2 times screening.

- Q:Does the chimney have high acid resistance?

- The acid resistant bricks used for chimney are usually made of custom-made trapezoidal acid proof bricks, and the physical and chemical indexes of acid resistant bricks need to be confirmed according to the chimney's actual emission. At this point, you can consult our kerei refractories.

- Q:Is there a construction picture for the acid proof brick in the pickle pond?

- Acid resistant brick, acid resistant ceramic tile in the shop, many users only pay attention to beauty, and use not leave seam shop, or shop too tight, too close, easy to leave hidden dangers for the future.

- Q:What is acid proof brick

- Acid proof brick is made of quartz, feldspar, clay as the main raw material, made by high temperature oxidation corrosion resistant materials, resistant to high pH, low water absorption, is not easy to be oxidized at room temperature, the media can not easily be pollution performance, except hydrofluoric acid and hot phosphoric acid, the temperature of chlorine saline, hydrochloric acid, sulfuric acid and nitric acid and at room temperature in any concentration of alkali, corrosion resistance are excellent.

- Q:Consult: water treatment room anticorrosive usable granite and acid resisting brick, these two kinds of material what?

- You can look at RZG/, the proportion of Rizhao garnet, high hardness, good toughness, wear resistance, acid and alkali resistance, flushing, moderate porosity, in the field of sewage treatment is widely used as a high density filter (heavy medium filter).

- Q:Construction method of acid proof brick

- Construction methodLining adhesive layer, mortar protection layer: lining carbon brick before, in the bottom board first put a layer of delta =3mm cement whole surface layer, in order to protect the lining layer and avoid mortar joint layer appear blind seam, curing at normal temperature after masonry.Positioning, layout and layout: according to the bottom of the groove size, first play the central cross line, then positioning, line, according to the line for typesetting, painting, cutting and numbering.Lining procedures: masonry procedures from low to high, the first base, the rear wall, the Yin angle, the facade to suppress the plane, Yang Kok plane cover the facade.Masonry method: the bottom and wall are all made by squeezing, kneading and extruding, and they are made by line by line, layer by layer, block by block.The prepared mortar evenly scraping on the three surfaces of carbon brick (i.e., on the back end, and then squeeze (side), rubber hammer) is dense, the ash seam and the combined layer clay full, squeeze out excess clay to eradicate. The surface shall be made of flat and vertical, rows and rows, and the seams between floors and layers shall be staggered.

- Q:98% acid tank cofferdam can use acid resistant brick?

- The hydrogenation unit has a large amount of light hydrocarbons in its memory, and if it leaks, it will cause serious accidents. Therefore, we should pay enough attention to the operation of the light hydrocarbon pump.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Acid Resistance Alumina Ceramic Lining Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords