All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

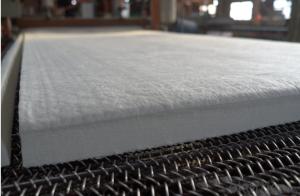

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Monolithic RefractoriesView More

Ceramic Fiber ProductsView More

Refractory BricksView More

Raw Materials For RefractoryView More

Q & A

How do refractory materials impact air pollution?

Refractory materials can impact air pollution by reducing emissions and improving combustion efficiency in industrial processes. These materials, with their heat-resistant properties, can withstand high temperatures and help contain and prevent the release of harmful gases and particulate matter into the air. By minimizing air pollution from industrial operations, refractory materials contribute to a cleaner and healthier environment.

How do refractory materials withstand the corrosive chemicals in the pulp and paper industry?

Refractory materials in the pulp and paper industry withstand corrosive chemicals through their unique properties that make them resistant to chemical reactions and high temperatures. These materials are designed to have high melting points and low thermal conductivity, which allows them to withstand the harsh conditions encountered in the industry. Additionally, refractory materials are chemically stable and inert, meaning they do not easily react with the corrosive chemicals present in the pulp and paper processes. This combination of properties enables refractory materials to provide long-lasting protection against chemical corrosion in the industry.

What are the advantages of using refractory castables?

There are several advantages of using refractory castables. Firstly, they offer excellent thermal insulation properties, allowing for efficient heat retention and energy savings. Additionally, castables can be easily shaped and molded into complex designs, providing flexibility in application and installation. They also have high resistance to thermal shock and abrasion, ensuring durability and prolonging the lifespan of the refractory lining. Furthermore, castables have good chemical resistance, making them suitable for various industrial processes involving corrosive substances. Overall, refractory castables offer a cost-effective solution with superior performance in high-temperature environments.

How are refractory materials used in the food processing industry?

Refractory materials are used in the food processing industry for various applications such as lining furnaces, kilns, and ovens, as well as insulating equipment and structures. These materials have high heat resistance and can withstand extreme temperatures, making them ideal for processes that involve baking, cooking, and heating. By using refractory materials, the food processing industry can ensure efficient and safe operations, maintain temperature control, and prevent contamination or degradation of food products.

Wholesale Refractory Materials from supplier in Ukraine

Whether you require refractory bricks, castables, or insulation materials, we have you covered. Our team of experienced professionals is committed to understanding your specific requirements and recommending the most suitable products for your applications.

In addition to our wide range of products, we offer competitive pricing and flexible delivery options to ensure a hassle-free procurement process. Our dedicated sales team is available to provide you with detailed quotations, ensuring transparency and cost-efficiency.

Furthermore, we understand the importance of technical support in the successful implementation of your projects. Our experts are readily available to offer guidance and assistance throughout the entire process, from product selection to installation and maintenance.

As a subsidiary of CNBM, we have access to a vast network of resources and industry-leading technologies. This allows us to stay at the forefront of the refractory materials market, constantly updating our product offerings to meet the evolving needs of our customers.

Whether you are in the steel, cement, glass, or other industries requiring refractory materials, we are here to serve you. Contact us today to experience our seamless procurement solutions and benefit from our extensive expertise in refractory materials in Ukraine.

In addition to our wide range of products, we offer competitive pricing and flexible delivery options to ensure a hassle-free procurement process. Our dedicated sales team is available to provide you with detailed quotations, ensuring transparency and cost-efficiency.

Furthermore, we understand the importance of technical support in the successful implementation of your projects. Our experts are readily available to offer guidance and assistance throughout the entire process, from product selection to installation and maintenance.

As a subsidiary of CNBM, we have access to a vast network of resources and industry-leading technologies. This allows us to stay at the forefront of the refractory materials market, constantly updating our product offerings to meet the evolving needs of our customers.

Whether you are in the steel, cement, glass, or other industries requiring refractory materials, we are here to serve you. Contact us today to experience our seamless procurement solutions and benefit from our extensive expertise in refractory materials in Ukraine.

Hot Search

- Monolithic Refractories in Somalia

- Ceramic Fiber Products in Cameroon

- Refractory Bricks in Sri Lanka

- Raw Materials For Refractory in Mozambique

- Monolithic Refractories in Madagascar

- Raw Materials For Refractory in Togo

- Monolithic Refractories in Belize

- Refractory Bricks in Comoros

- Raw Materials For Refractory in Malta

- Raw Materials For Refractory in Spain