All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Fiberglass Chopped StrandView More

Fiberglass Mesh ClothView More

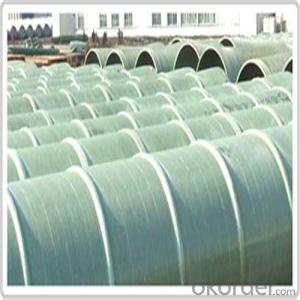

Composite PipesView More

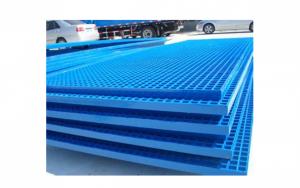

FRP Pultrusion ProfilesView More

Fiberglass Mat TissueView More

Fiberglass FabricsView More

Fiberglass MeshView More

Composite TankView More

Fiberglass Mesh tapeView More

PolymerView More

FRP Roofing PanelView More

Fiberglass RovingView More

Q & A

Can fiberglass be used for waterproofing?

Yes, fiberglass can be used for waterproofing.

How is fiberglass used in the aerospace industry?

Fiberglass is extensively used in the aerospace industry for various applications. It is commonly used in the construction of aircraft components such as fairings, radomes, and wingtips due to its lightweight, high strength, and excellent resistance to corrosion. Fiberglass composites also play a crucial role in the production of aircraft interiors, including panels, seats, and cabin fittings, as they offer a balance of strength, durability, and fire resistance. Moreover, fiberglass-reinforced polymers are employed in the manufacturing of rocket fairings and payload structures due to their exceptional strength-to-weight ratio, enabling efficient space exploration.

How is fiberglass supply shaped?

Fiberglass supply is typically shaped through the process of laying up multiple layers of fiberglass fabric or matting onto a mold or form, and then saturating it with resin. This allows the fiberglass to conform to the desired shape of the mold or form, creating a strong and durable final product.

How long does it take for fiberglass to cure?

The curing time for fiberglass can vary depending on various factors such as temperature, humidity, and the specific type of resin used. Generally, it can take anywhere from a few hours to several days for fiberglass to fully cure.

Are there any safety precautions to consider when working with fiberglass?

Yes, there are several safety precautions to consider when working with fiberglass. It is important to wear proper protective equipment such as gloves, goggles, and a respirator to prevent skin, eye, and respiratory irritation. Additionally, working in a well-ventilated area or using exhaust fans can help minimize exposure to harmful fumes. It is crucial to handle fiberglass materials carefully to avoid cuts or punctures and to dispose of any waste properly. Following these safety precautions can help prevent potential health hazards associated with working with fiberglass.

Wholesale Fiberglass Supply from supplier in Ukraine

Whether you are looking for fiberglass insulation, fiberglass reinforced plastic (FRP) panels, fiberglass pipes, or any other fiberglass supplies, we have you covered. Our team of knowledgeable professionals is ready to assist you in finding the right products that meet your specific requirements.

In addition to our wide product range, we also offer competitive pricing and efficient delivery options to ensure a seamless procurement process. We understand the importance of timely delivery and strive to meet your project timelines.

Furthermore, our technical support services are designed to provide you with the necessary guidance and assistance throughout your projects. Whether you need help with product selection, installation, or any other technical aspect, our experts are here to support you.

As a subsidiary of CNBM, we have access to a global network of resources and expertise, enabling us to provide you with top-notch fiberglass supply solutions. We are committed to meeting and exceeding your expectations, ensuring your satisfaction with every interaction.

Contact us today and let us be your trusted partner for all your fiberglass supply needs in Ukraine.

In addition to our wide product range, we also offer competitive pricing and efficient delivery options to ensure a seamless procurement process. We understand the importance of timely delivery and strive to meet your project timelines.

Furthermore, our technical support services are designed to provide you with the necessary guidance and assistance throughout your projects. Whether you need help with product selection, installation, or any other technical aspect, our experts are here to support you.

As a subsidiary of CNBM, we have access to a global network of resources and expertise, enabling us to provide you with top-notch fiberglass supply solutions. We are committed to meeting and exceeding your expectations, ensuring your satisfaction with every interaction.

Contact us today and let us be your trusted partner for all your fiberglass supply needs in Ukraine.

Hot Search

- Fiberglass Chopped Strand in Mongolia

- Fiberglass Mesh Cloth in Finland

- Composite Pipes in Montenegro

- FRP Pultrusion Profiles in Uruguay

- Fiberglass Mat Tissue in Peru

- Fiberglass Fabrics in Turkmenistan

- Fiberglass Mesh in Bhutan

- Composite Tank in Togo

- Fiberglass Mesh tape in Mexico

- Polymer in Palestine