All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

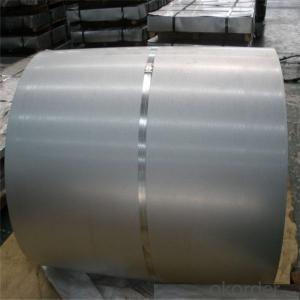

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How are stainless steel coils used in heat exchangers?

Stainless steel coils are commonly used in heat exchangers due to their excellent heat transfer properties and corrosion resistance. These coils are designed to efficiently transfer heat between two fluids by allowing one fluid to flow through the inner coil while the other flows around it. This allows for efficient heat exchange and prevents the fluids from mixing. Stainless steel coils are ideal for this application as they can withstand high temperatures, resist corrosion from various chemicals, and maintain their structural integrity over time.

How is stainless steel coil priced?

Stainless steel coil is priced based on various factors such as the grade and quality of the stainless steel, the market demand and supply dynamics, the size and thickness of the coil, and the additional processing or finishing required. Additionally, factors like transportation costs, currency exchange rates, and any applicable taxes or tariffs can also influence the pricing of stainless steel coil.

How is stainless steel coil used in the brewing manufacturing industry?

Stainless steel coil is widely used in the brewing manufacturing industry for various applications. It is primarily used in the construction of fermentation tanks, storage vessels, and piping systems. The corrosion-resistant properties of stainless steel make it an ideal choice for storing and transporting beer, as it does not react with the beverage and maintains its quality. Additionally, stainless steel coils are also used in heat exchangers, where they help in maintaining the desired temperature during the brewing process. Overall, stainless steel coil plays a crucial role in ensuring the efficiency, cleanliness, and quality of beer production in the brewing manufacturing industry.

Are stainless steel coils recyclable?

Yes, stainless steel coils are recyclable. Stainless steel is a highly recyclable material, and the coils can be melted down and reused in the production of new stainless steel products.

How does electroplating affect the surface of a stainless steel coil?

Electroplating can significantly enhance the surface properties of a stainless steel coil. By applying a thin layer of a different metal through electroplating, the coil's surface can become more resistant to corrosion, wear, and oxidation. Additionally, electroplating can improve the coil's appearance by providing a smooth and polished finish, making it more visually appealing.

Wholesale Stainless Steel Coil from supplier in Ukraine

Our team of experts is highly knowledgeable and experienced in the stainless steel industry, ensuring that we can provide you with the best quality products and services. We understand the specific requirements of the Ukrainian market and can tailor our offerings to meet your needs.

Whether you are looking for standard stainless steel coils or customized solutions, we can provide you with a wide range of options. Our products are sourced from reliable manufacturers and undergo rigorous quality control processes to ensure that they meet the highest international standards.

Furthermore, our technical support team is always available to assist you with any questions or concerns you may have. We can provide guidance on product selection, installation, and maintenance to ensure that you get the most out of your stainless steel coils.

As part of CNBM, we have access to a vast network of suppliers and resources, allowing us to offer competitive prices and efficient delivery times. We are committed to providing you with the best value for your money and ensuring that your projects are completed on time and within budget.

Partnering with us means that you will have a reliable and dedicated supplier for all your stainless steel coil needs in Ukraine. Contact us today to discuss your requirements and let us show you how we can add value to your projects.

Whether you are looking for standard stainless steel coils or customized solutions, we can provide you with a wide range of options. Our products are sourced from reliable manufacturers and undergo rigorous quality control processes to ensure that they meet the highest international standards.

Furthermore, our technical support team is always available to assist you with any questions or concerns you may have. We can provide guidance on product selection, installation, and maintenance to ensure that you get the most out of your stainless steel coils.

As part of CNBM, we have access to a vast network of suppliers and resources, allowing us to offer competitive prices and efficient delivery times. We are committed to providing you with the best value for your money and ensuring that your projects are completed on time and within budget.

Partnering with us means that you will have a reliable and dedicated supplier for all your stainless steel coil needs in Ukraine. Contact us today to discuss your requirements and let us show you how we can add value to your projects.