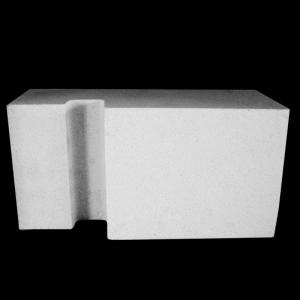

Acid Resistance Brick with Stable Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quality Acid Resistant Brick

Product Description:

Packaging & Delivery

Packaging Details: | wood box packed with foam board |

Delivery Detail: | 5-15days |

High purity acid resistant alumina ceramic lining brick

According to different customers using environment, raw materials of the products are strictly managed so that we can ensure that the product not only has good wear-resistant, Corrosion-resistant, but also size rich. The service life can be at least five years, and has 15% higher grinding efficiency than a rubber liner. Also it decreases the pollution to the grinding material and increases the capacity of mill ball, lowering the cost.

Alumina ceramic lining brick tile Product Feature

Alumina purity as high as 99.5%.

Fine grinded surface,

Tight tolerance,

High temperature

Alumina ceramic lining brick tile specification/models

10x10x1mm, 20x20x2mm, 40x40x8mm, 100x60x8mm, 150x150x12.5mm, 200x200x25mm etc. Can be made according to your requirements.

Alumina ceramic lining brick tile chemical composition and technical data:

Performance Index | 92 series | 95series |

Al2O3 (%) | ≥91.5 | ≥94.5 |

Hardness (Moh’s) | 9 | 9 |

Water Absorption Rate (%) | 0.02 | 0.02 |

Fracture Toughness (Mpa) | 3.65 | 3.75 |

Bending | 255 | 275 |

Bulk density(g/cm 3 ) | ≥ 3.60 | 3.65 |

High purity alumina plates can stand 1700C at most, widely used in furnace kilns and other applications.

Alumina ceramic lining brick tile advantages:

1. The main material of our products is high purity quality alumina, which cause no negative effective effect to the grinded material.

2. High density and hardness, impact resistance, low loss rate, smooth surface and no contamination to product.

3. With high grinding efficiency which can reduce grinding time to reduce energy cost and being good for environment protection.

Alumina ceramic lining brick tile application

Working in high temperature environment.

Abrasive application etc

High quality Alumina Grinding Media (Alumina Ball and Lining Brick) are made from selected high grade raw material and fired in high temperature by advanced cool iso-static pressing technique and automatic molding process. We are working for customers' demands and offering the products with best performance price ratio. With advantages of high density, regular shape, easily classifying and assorting, superior milling efficiency and competitive price prior to natural pebbles and conventional grinding media, Alumina Ball and Lining Brick have been approved to be excellent for grinding processing of ceramic bodies and glaze materials in tile industries and surface polishing of the ceramic bearing applicant and surly the best choice to replace the pebbles. Based on different applying fields, we have developed the relevant grades and series, which meet the customers' consideration on the use and cost control, and have gained the good reputation from clients domestic and oversea.

- Q:Acid resistant brick lining, engineering scaffolding, how to take?

- Material preparation: the anti-corrosion materials used in this project are stored in the appropriate warehouse (site), and the incoming materials are tested to comply with the requirements of the HGJ229-91 specification. Equipment preparation: cutting machine, mixer, grinder, trolley, cement plate, rope

- Q:Is acid proof brick alkali resistant?

- Absolutely neutral materials do not react with acids, nor react with alkalis, and do not react at higher pressures and temperatures. Of course, this condition is not endless.

- Q:How to clean the acid brick surface dirt?

- Daily cleaning of bricks can be done with detergent, soap and other cleaning.

- Q:What is anticorrosive floor tile?

- The above construction method is simple, and the normal paving tiles are the same. It is convenient to add 2-3mm cross micelles when leaving gaps.

- Q:Does the chimney have high acid resistance?

- The chimney particles and gases, mostly coal tar products, material acidic, therefore, take good acid resistance, acid proof brick, Grouts also used potassium silicate clay acid is preferred. If it is an ordinary high alumina brick, it does not meet the requirements of acid resistance, and only the chimney lined with acid resistant bricks.

- Q:What is acid proof brick

- Acid proof brick is made of quartz, feldspar, clay as the main raw material, made by high temperature oxidation corrosion resistant materials, resistant to high pH, low water absorption, is not easy to be oxidized at room temperature, the media can not easily be pollution performance, except hydrofluoric acid and hot phosphoric acid, the temperature of chlorine saline, hydrochloric acid, sulfuric acid and nitric acid and at room temperature in any concentration of alkali, corrosion resistance are excellent.

- Q:Consult: water treatment room anticorrosive usable granite and acid resisting brick, these two kinds of material what?

- You can look at RZG/, the proportion of Rizhao garnet, high hardness, good toughness, wear resistance, acid and alkali resistance, flushing, moderate porosity, in the field of sewage treatment is widely used as a high density filter (heavy medium filter).

- Q:Construction method of acid proof brick

- Construction preparationFamiliar with drawings, specifications, technical disclosure, do a good job of the handover process.Material preparation: the anti-corrosion materials used in this project are stored in the appropriate warehouse (site), and the incoming materials are tested to comply with the requirements of the HGJ229-91 specification.Equipment preparation: cutting machine, mixer, grinder, trolley, cement plate, rope, hose, shovel, wipe, steel scraper, rubber hammer, steel wire brush, brush, putty knife, the level of scale, by foot, rope, wire, small pendant, Jue measuring cup, scales, tarps, ventilation and lighting equipment.

- Q:Acid proof brick, acid resistant porcelain in the paste process with no seam

- As the base layer, bonding layer and acid brick itself thermal expansion, cold shrinkage coefficient is very different, in 1-2 years of hot and cold tension failure, too dense paving easily lead to acid brick swelling, fracture and other issues

- Q:What is acid proof tile, acidproof ceramic tile brand introduction?

- Among them, the detection of acidity and alkalinity is one of them. The state has relevant standards.Among them, the inspection standard of glazed tiles is different from that of polished tiles.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Acid Resistance Brick with Stable Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords