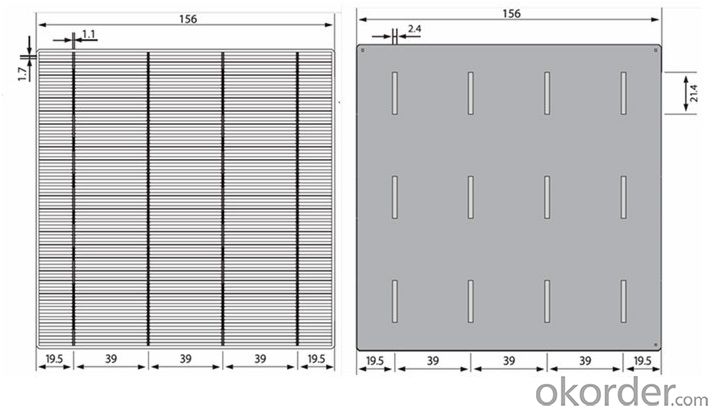

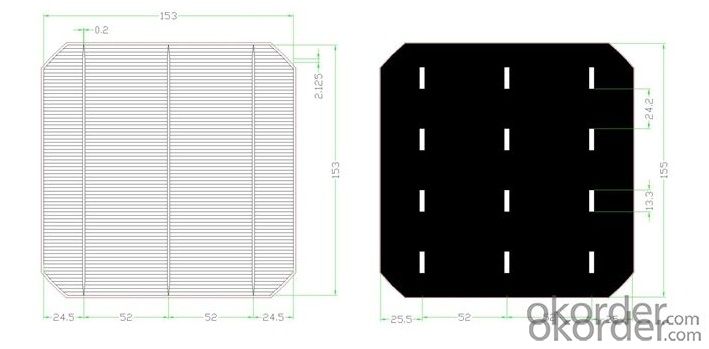

Grade A 156x156mm Poly Stable Quality Solar Cell

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Grade A 156x156mm Poly Stable Quality Solar Cell

Solar Module Summarize

Solar Module is the core part of solar PV power systems,also is the highest value part of it. The function of Solor Module is to convert the sun's radiation to electrical energy, or transfer it to battery and store in it, or to drive the load running.

The Product has been widely used in space and ground, it mainly used for power generation systems, charging systems, road lighting and traffic signs areas. It could offer a wide range of power and voltage, and with high conversion efficiency, and long service life.

Solar Module Specifications

Mono 80W—100W

Module | Type (36 Series) | |||||

Encapsulation | Glass/EVA/Cells/EVA/TPT | |||||

Parameters | SNM-M80(36) | SNM-M85(36) | SNM-M90(36) | SNM-M95(36) | SNM-M100(36) | |

Max power | Pm(W) | 80W | 85W | 90W | 95W | 100W |

Tolerance | +/-3% | |||||

Open circuit voltage | Voc(V) | 21.2 | 21.8 | 21.8 | 22.3 | 22.6 |

Short circuit current | Isc(A) | 4.84 | 5.00 | 5.30 | 5.44 | 5.68 |

Max. power voltage | Vmp(V) | 17.5 | 18.0 | 18.0 | 18.5 | 18.5 |

Max. power current | Imp(A) | 4.57 | 4.72 | 5.00 | 5.14 | 5.40 |

Dimensions | (L*W*H) | 1200x540x35mm | ||||

Net Weight | (kg) | 9 | ||||

Max. system voltage | (V) | 1000VDC | ||||

Operate Temp. Scope | -40/+85'C | |||||

Resistance | 227g steel ball fall down from 1m height and 120m/s wind | |||||

Warranty | Pm is no less 90% in 10 years and no less 80% in 25 years | |||||

STC | (Standard Test Condition: 1000W/m2, AM1.5, and 25'C) | |||||

Picture show

- Q:What is the role of junction boxes on solar silicon wafers?

- Junction boxes on solar silicon wafers serve as protective enclosures that house the electrical connections and components of a solar panel. They are responsible for managing the flow of electricity generated by the solar cells, ensuring proper connections, and providing protection against environmental factors such as moisture and dust. Additionally, junction boxes often include features like diodes and bypass capacitors to optimize the performance and safety of the solar panel.

- Q:Can solar silicon wafers be used in solar-powered water desalination systems?

- Yes, solar silicon wafers can be used in solar-powered water desalination systems. Solar silicon wafers are commonly used in photovoltaic cells to generate electricity from sunlight. In a solar-powered water desalination system, these wafers can be used to capture sunlight and convert it into electricity, which can then be used to power the desalination process. This allows for a sustainable and environmentally friendly solution to produce clean drinking water from seawater or brackish water sources.

- Q:Can solar silicon wafers be used in solar-powered medical devices?

- Yes, solar silicon wafers can be used in solar-powered medical devices. Solar silicon wafers are commonly used in solar panels to convert sunlight into electricity, and this electricity can be utilized to power various medical devices, including those used in remote or off-grid areas. By harnessing solar energy, these devices can operate independently without relying on traditional power sources, making them more sustainable and accessible in diverse healthcare settings.

- Q:What is the expected efficiency improvement for tandem perovskite-silicon solar silicon wafers?

- The expected efficiency improvement for tandem perovskite-silicon solar silicon wafers is significant, potentially reaching beyond 30%.

- Q:How do solar silicon wafers perform in different weather conditions?

- Solar silicon wafers perform well in a variety of weather conditions. While they may produce slightly less electricity during cloudy or overcast weather, they still generate energy due to their ability to convert sunlight into electricity. Rain, snow, or extreme temperatures do not significantly affect their performance, as they are designed to withstand such conditions. However, it is important to note that they perform optimally under direct sunlight, resulting in the highest energy production.

- Q:What is the role of a solar silicon wafer in a solar panel?

- The role of a solar silicon wafer in a solar panel is to absorb sunlight and convert it into electricity. The wafer is made of silicon, which is a semiconductor material that can generate an electric current when exposed to light. Multiple silicon wafers are arranged in a solar panel to maximize the absorption of sunlight and produce a higher amount of electrical energy.

- Q:How are solar silicon wafers tested for mechanical strength and durability?

- Solar silicon wafers are tested for mechanical strength and durability through a series of rigorous tests. These tests typically involve subjecting the wafers to various mechanical stresses and environmental conditions to simulate real-world conditions. Some common tests include bend and flex tests, where the wafers are subjected to controlled bending forces, and impact tests, where they are exposed to physical impacts. Additionally, thermal cycling tests are performed to assess the wafers' ability to withstand extreme temperature changes. These tests help determine the structural integrity and durability of solar silicon wafers, ensuring their reliability and performance in solar cell applications.

- Q:How are solar silicon wafers integrated into the electrical grid?

- Solar silicon wafers, which are the key component of solar panels, are integrated into the electrical grid through a series of steps. First, the solar panels made from silicon wafers are installed on rooftops, open spaces, or solar farms where they can capture sunlight. The panels convert sunlight into direct current (DC) electricity. To integrate this DC electricity into the electrical grid, an inverter is used to convert the DC electricity into alternating current (AC) electricity, which is the form of electricity used in the grid. The AC electricity produced by the solar panels is then connected to the electrical grid through a bi-directional meter. This meter measures the electricity produced by the solar panels and any excess electricity generated can be fed back into the grid, earning credits or reducing the energy bill of the owner. This integration allows the solar energy to be directly used by consumers or distributed to the wider electrical grid, contributing to the overall energy supply.

- Q:What is the weight of a solar silicon wafer?

- The weight of a solar silicon wafer can vary depending on its size and thickness. On average, a standard silicon wafer used in solar panels typically weighs around 4 to 7 grams.

- Q:How are solar silicon wafers protected from hailstorms?

- Solar silicon wafers are typically protected from hailstorms through the use of tempered glass covers that act as a shield. These covers are designed to be highly durable and impact-resistant, capable of withstanding the force of hailstones. Additionally, some solar panels may also incorporate anti-reflective coatings or laminates to enhance their resistance against hail damage.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Grade A 156x156mm Poly Stable Quality Solar Cell

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products