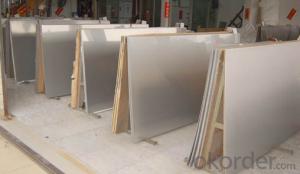

Stainless Steel 304 sheet with competitive pricing and top quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stainless steel 304 sheet

Company advantage of stainless steel:

-Top Equipments, Leading In The Industry.

- Professional Team, Leading Innovation.

- Huge Supply Capacity Advantage, Timely and Effective Delivery.

- Modern Logistic, Fact and Convenient.

- Precise Manufacturing, Exquisite Products.

- Serve People, Create Value.

- Dimensional Network, Powerful Expansion.

Product Information of stainless steel sheet:

- Q:What are the different types of stainless steel pipe elbows?

- There are several different types of stainless steel pipe elbows, each designed for specific applications and requirements. Some of the common types include: 1. 90-degree elbow: This type of elbow is the most commonly used and is designed to change the direction of the pipe by 90 degrees. It is available in different sizes and materials to suit various needs. 2. 45-degree elbow: Similar to the 90-degree elbow, the 45-degree elbow is used to change the pipe direction but at a smaller angle of 45 degrees. It is often used in situations where a sharper change in direction is required. 3. Long radius elbow: This type of elbow has a larger radius, resulting in a smoother flow of fluids. It is commonly used in applications where the flow rate is critical, such as in the oil and gas industry. 4. Short radius elbow: As the name suggests, the short radius elbow has a smaller radius compared to the long radius elbow. It is often used in tight spaces where a sharp change in direction is necessary. 5. Reducing elbow: This type of elbow is used when the pipe size needs to be reduced, resulting in a change in the diameter of the pipe. It is commonly used in plumbing systems where different pipe sizes need to be connected. 6. Welded elbow: Welded elbows are fabricated by joining two separate sections of pipe using welding techniques. They are strong and durable, making them suitable for high-pressure applications. 7. Threaded elbow: Threaded elbows have female threads on both ends, allowing them to be easily connected to other threaded pipes or fittings. They are commonly used in plumbing systems and can be easily disassembled if needed. 8. Flanged elbow: Flanged elbows have flanges on both ends, which are bolted together to create a secure connection. They are often used in applications that require frequent disassembly or where a high level of strength is required. These are just a few examples of the different types of stainless steel pipe elbows available in the market. The choice of elbow depends on the specific requirements of the application, such as the pipe size, fluid flow rate, pressure, and temperature. It is important to select the appropriate type of elbow to ensure efficient and safe operation of the piping system.

- Q:Can stainless steel pipes be used in power plants?

- Yes, stainless steel pipes can be used in power plants. Stainless steel has excellent corrosion resistance, high-temperature strength, and durability, making it suitable for various applications in power plants, including transporting fluids and gases, supporting structural components, and handling high-pressure environments.

- Q:Can stainless steel pipes be used in harsh environments?

- Yes, stainless steel pipes can be used in harsh environments. Stainless steel is highly resistant to corrosion, rust, and high temperatures, making it suitable for a variety of challenging conditions such as chemical processing plants, offshore oil rigs, and industrial settings. Its durability and resistance to environmental factors make it a reliable choice for harsh environments.

- Q:Can stainless steel pipes be insulated with polycarbonate?

- No, stainless steel pipes cannot be insulated with polycarbonate. Polycarbonate is a type of thermoplastic material that is typically used for its transparency, impact resistance, and insulation properties. While it can be used to insulate certain types of pipes, such as PVC or copper, it is not suitable for insulating stainless steel pipes. Stainless steel pipes are generally used for high-temperature applications or corrosive environments, and require insulation materials that can withstand these conditions. Therefore, it is recommended to use insulation materials specifically designed for stainless steel pipes, such as mineral wool, fiberglass, or foam pipe insulation.

- Q:How do stainless steel pipes perform in extreme weather conditions?

- Stainless steel pipes are known for their excellent performance and durability in extreme weather conditions. Due to their unique composition, stainless steel pipes have a high resistance to corrosion, making them ideal for use in various environments, including extreme weather conditions. In extremely cold weather, stainless steel pipes retain their strength and flexibility, unlike other materials that may become brittle or crack. This makes them suitable for applications such as oil and gas pipelines, where they can withstand low temperatures without compromising their performance. Similarly, in extremely hot weather, stainless steel pipes exhibit excellent heat resistance, preventing them from warping or deforming. This quality is crucial in industries like power generation, where high-temperature environments are common. Furthermore, stainless steel pipes have a high melting point, enabling them to maintain their structural integrity even in the presence of intense heat. This makes them resistant to fire damage, making them a safe choice for applications that require fire protection. Stainless steel pipes also have exceptional resistance to UV radiation, which can be damaging over time. This property ensures that the pipes do not degrade or weaken when exposed to direct sunlight or extreme weather conditions, making them suitable for outdoor applications. Additionally, stainless steel pipes have excellent mechanical properties, including high tensile strength and impact resistance. These qualities allow them to withstand extreme weather conditions such as high winds, heavy storms, and seismic activities without undergoing structural failures. In conclusion, stainless steel pipes are highly reliable and perform exceptionally well in extreme weather conditions. Their resistance to corrosion, high and low temperatures, UV radiation, and mechanical stress makes them a preferred choice for various industries, ensuring reliable and long-lasting performance even in the harshest environments.

- Q:Can stainless steel pipes be insulated with polyethylene naphthalate?

- Indeed, polyethylene naphthalate (PEN) is a viable option for insulating stainless steel pipes. PEN, a top-notch thermoplastic material, boasts impressive insulation capabilities. Its low thermal conductivity qualifies it to effectively insulate pipes, guarding against heat loss or gain. Moreover, PEN exhibits commendable resistance to chemicals, moisture, and UV radiation, making it a robust choice for pipe insulation. Nevertheless, it is crucial to verify the compatibility of the chosen insulation material with the unique application and operating conditions to guarantee optimal performance and durability.

- Q:Can stainless steel pipes be used for power generation applications?

- Yes, stainless steel pipes can be used for power generation applications. Stainless steel is a popular choice for pipes in power generation due to its high corrosion resistance, durability, and strength. It can withstand high temperatures and pressures, making it suitable for various power generation processes such as thermal power plants, nuclear power plants, and hydroelectric power plants. Stainless steel pipes are commonly used in power generation applications for several reasons. Firstly, stainless steel has excellent resistance to corrosion, both from high-temperature steam and chemicals commonly used in power generation processes. This resistance ensures that the pipes remain intact and reliable over a long period of time, reducing maintenance and replacement costs. Secondly, stainless steel pipes are known for their durability and strength. They can withstand the high pressures and temperatures generated during power generation without deforming or breaking. This is crucial for ensuring the safety and efficiency of power generation systems. Furthermore, stainless steel is also highly resistant to scaling and fouling, which can occur in power generation applications due to the presence of impurities in water or steam. The smooth surface of stainless steel pipes helps minimize the buildup of deposits, ensuring efficient heat transfer and preventing clogging or blockage. Lastly, stainless steel pipes are compatible with a wide range of power generation fuels, including coal, natural gas, oil, and renewable energy sources. They can handle the corrosive effects of these fuels and maintain their structural integrity. In summary, stainless steel pipes are well-suited for power generation applications due to their corrosion resistance, durability, strength, and compatibility with various fuels. They offer a reliable and long-lasting solution for transporting fluids and gases in power generation systems.

- Q:Can stainless steel pipes be lined with polyethylene?

- Yes, stainless steel pipes can be lined with polyethylene. This lining provides additional corrosion resistance to the stainless steel pipes, making them suitable for various applications in industries such as oil and gas, water treatment, and chemical processing.

- Q:Can stainless steel pipes be insulated with polyethylene-terephthalate glycol?

- No, stainless steel pipes cannot be insulated with polyethylene-terephthalate glycol.

- Q:Are stainless steel pipes magnetic?

- The magnetic nature of stainless steel pipes depends on the specific grade. Stainless steel is primarily composed of iron, along with chromium, nickel, and other elements in varying proportions. The magnetic properties of stainless steel are influenced by the presence of these elements. Typically, stainless steel grades with higher chromium and nickel content, such as austenitic grades (e.g., 304, 316), are not magnetic. Conversely, stainless steel grades with more ferrite, like martensitic and ferritic grades, can exhibit magnetic properties. Hence, it is crucial to consider the grade of stainless steel to ascertain its magnetic behavior.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel 304 sheet with competitive pricing and top quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords