Spiral plate heat exchanger(Detachable)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The spiralplate heat exchanger is a high-efficient heat exchanging equipment used inalcohol, solvent, food ferment, pharmaceutical, petrochemical, refrigeration,organic chemistry, metallurgical industry, suitable for convection heattransfer of liquidtoliquid,gas to gas, gas to liquid.

The spiralplate heat exchanger comprises detachable and nondetachable exchanger. Thespiral plate heat exchanger is made of carbon steel and stainless steel.

The argument list of carbon steel spiral plate heat exchanger

公称换热面积m2 | 通道间距m2 | 计算换热面积m2 | 流速1m/sec时处理量m3/h | 接管公称直径dg | 型 号 | 质 量(kg) I6T型 II6T型 | |

40 | 10 | 40.9 | 20.9 | 80 | I6.II6T40-0.6/1200-10 | 1730 | 2772 |

14 | 42.3 | 39.3 | 100 | I6.II6T40-0.8/1200-14 | 1843 | 2835 | |

18 | 44.9 | 63.5 | 125 | I6.II6T40-1.0/1200-18 | 2069 | 3061 | |

50 | 10 | 50.2 | 35.3 | 100 | I6.II6T50-1.0/1000-10 | 2334 | 3070 |

14 | 53.2 | 49.4 | 125 | I6.II6T40-1.0/1200-14 | 2408 | 3400 | |

18 | 54.0 | 76.3 | 125 | I6.II6T40-1.2/1200-18 | 2430 | 3422 | |

60 | 10 | 60.8 | 20.9 | 80 | I6.II6T60-0.6/1400-10 | 2673 | 4231 |

14 | 60.7 | 39.3 | 100 | I6.II6T60-0.8/1400-14 | 2750 | 4308 | |

18 | 61.6 | 63.5 | 125 | I6.II6T60-1.0/1400-18 | 3097 | 4655 | |

80 | 10 | 81.4 | 28.1 | 100 | I6.II6T60-1.0/1400-10 | 3365 | 4923 |

14 | 80.6 | 39.3 | 100 | I6.II6T80-0.8/1600-14 | 3445 | 5796 | |

18 | 82.0 | 63.5 | 125 | I6.II6T80-1.0/1600-18 | 3682 | 6033 | |

100 | 10 | 101.4 | 28.1 | 100 | I6.II6T100-1.0/1600-10 | 4250 | 6601 |

14 | 101.8 | 49.4 | 125 | I6.II6T100-1.0/1600-14 | 4390 | 6741 | |

18 | 108.2 | 76.3 | 125 | I6.II6T100-1.2/1600-18 | 4460 | 6811 | |

120 | 14 | 121.5 | 42.5 | 125 | I6.II6T120-1.2/1700-14 | 5130 | 7718 |

18 | 120.0 | 59.4 | 125 | I6.II6T120-1.2/1800-18 | 5250 | 7960 | |

130 | 14 | 130.5 | 32.5 | 125 | I6.II6T130-1.2/1800-14 | 5570 | 8280 |

18 | 131.0 | 49.4 | 125 | I6.II6T130-1.2/1900-18 | 5700 | 9005 | |

2.New Technology Description:

Five-ColumnThree-Effect Distillation Process

Our company designs and manufactures latestFive-ColumnThree-Effect Distillation equipment.This new process is promoted on the basisof traditional five-column differential-pressure column and mainly used forsuper-fine alcohol production.

The key of this process is the heatingmethods,the steam heats one column directly andtransfers theheat to other 4 columnsto achieve three-effect thermal couplingand energy-saving effects.

In terms of electricityefficiency, it can save 50% electricity and avoid the repairing ofcirculating pumps and also extend the working life of there-boilers.

Energy Consumption & Quality Indicator Table forSuper-fine Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗汽量Steam Consumption | t/t | 3.0 | 2.3 |

2 | 色度Colority | No. | 9.5 | 8 |

3 | 乙醇 Alcohol | %(v/v) | 95.5 | 96.5 |

4 | 硫酸试验Sulfuric Acid Test | No. | 70 | 9 |

5 | 醛(以乙醛计)Aldehyde (as acetaldehyde) | mg/l | 28 | 2 |

6 | 甲醇Methanol | mg/l | 18 | 3 |

7 | 正丙醇n-propyl alcohol | mg/l | 15 | 2 |

8 | 异丁醇+异戊醇Isobutanol+isoamylol | g/l | 27.5 | 2 |

9 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 9 |

10 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 16 |

11 | 不挥发物Nonvolatile matter | mg/l | 23 | 12 |

12 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.4 |

13 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 2 |

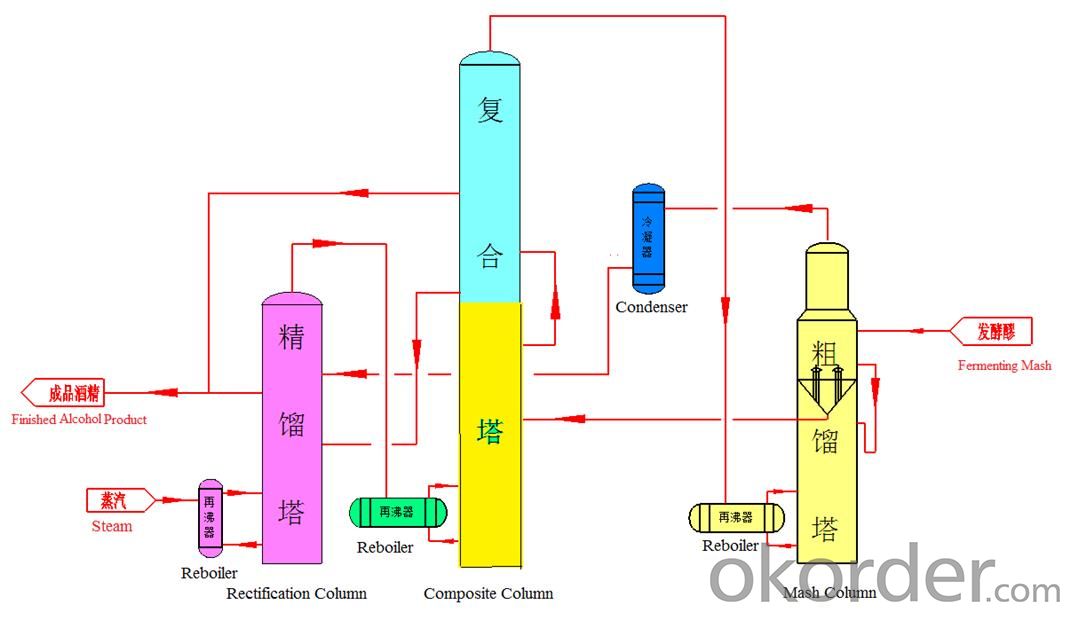

Double-Mash-Column Three-Effect Distillation Process

This process applies to the production ofgeneral-grade alcohol& fuel ethanol, and it was awarded Chinese nationalpatent, it is the onlysuccessfulapplicationof doublemash column & three-effect in the world,whichproduces general-grade alcohol.

This process is composed by mash column,rectification column and composite column. The composite column functions asmash column and rectification column.

The key of this process is the heatingmethods: the steam heats one column directly andtransfers the heat to other 2 columns to achieve three-effect thermal couplingand energy-saving effects.

The advantage of this process is energy-saving;itsaves over 40% steam

Energy Consumption & Quality Indicator Table for General-Grade Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗电量Electricity Consumption | kwh/t | 15 | 20 |

2 | 耗汽量Steam Consumption | t/t | 2.3 | 1.4 |

3 | 耗水量Water Consumption | t/t | 7 | 5 |

4 | 色度Colority | No. | 9.5 | 8 |

5 | 乙醇 Alcohol | %(v/v) | 95.5 | 95.5 |

6 | 硫酸试验Sulfuric Acid Test | No. | 70 | 55 |

7 | 醛Aldehyde (as acetaldehyde) | mg/l | 28 | 25 |

8 | 甲醇Methanol | mg/l | 100 | 55 |

9 | 正丙醇n-propyl alcohol | mg/l | 75 | 35 |

10 | 异丁醇+异戊醇Isobutanol+isoamylol | mg/l | 27.5 | 26 |

11 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 18 |

12 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 20 |

13 | 不挥发物Nonvolatile matter | mg/l | 23 | 21 |

14 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.5 |

15 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 3 |

3. Production Capability

1. Our company was established in the 1950s,designed and manufactured the first stainlesssteel distillation column in China.

2. Our company can produce6 full sets of equipment (including crushing section, liquefyingsaccharification section, fermentation section, distillation section and DDGSsection) in a

month.

3. Among 16 production workshops,3 workshops arefor mechanic manufacture, 5 workshops arefor manufacturing process, 8 workshopsare for assembling & welding.

4. We own advanced machining equipment and producttesting equipment.

4. Designed capability

1). We own Design License of SpecialEquipment D1 & D2 Class; Manufacture License of Special Equipment A2 Class;Design License of Special Equipment GC

Class.

2).Our company achieves more than 20 patentcertificates on distillation, DDGS, and other fields.

3). Ourcompany owns ASME certification, ISO 9001 Quality System Certification, ISO14001 Environmental Management System Certification & GB/T28001Occupational Health and Safety

Management System Certification

5. After-sales Service

1).Our company can provide a sophisticatedproduct after-sale service and can ensure the implementation, maintenance andcommission of projects.

2). We can reach the project site afterreceiving the user’s notification.

6.Package & Transport

- Q:OK, so this is a follow up question to my previous one where I said my furnace was blowing out cold air.The repair tech that came out said my heat exchanger is cracked. I told him that I replaced the original heat exchanger 4 years ago and the tech said that since the heat exchanger has a faulty design (which is on the manufacturer) a replaced heat exchanger is only good for about 5 years. He sugguested I get the entire furnace replaced and that putting a 2nd replaced heat exchanger in the furnace will cost you additional labor costs as well as going through the same problem again in a few years.Is this guy telling me something honest? or should I pursue in getting the heat exchanger replaced again?

- The only way you'd know for sure would be to get a second estimate done by another reputable company. And frankly, if I were laying out that sort of cash, I'd definitely get 2 or more estimates before settling on a repair.

- Q:why does the heat in my car work, but the air doesn't?

- because they are both types of heat exchangers but completely different.your heater system works by passing hot coolant(water/antifreeze mixture) through a heater core(kinda looks like a mini radiator) under your dash that then heats the air in your air vents and then gets blown onto you. you air conditioning system has more to do with the way your refrigerator works. it compresses freon and then allows it to rapidly expand inside a special component under the dash, thereby cooling the air in your air vents which then gets blown into your face on that hot summer day. there are many problems that can arise to make your air conditioner not work. take it to a mechanic to have it diagnosed. they may have to add freon just to find out what is wrong with it and then take it back out to change the part to make it work again and then put freon back in it so it blows cool air again. EDIT: Diggle you are an idiot. its not hot air from around your engine

- Q:Although we get heat from it we bought a much more powerfull one than was neccessary for the room in the hope the heat would spread into another room next to it where the entry was open. We seem to be able to heat ne room but nothing else. The insert came with no operating instructions and i wonder what we are doing wrong. There is a little sliding piece in the top with a +~- and a fan wuth two settings also a metal handle to turn to openand close the tube but when to do that will closing it slightly give us more heat? Any help would be appreciated.

- I am not familiar with inserts but heat with a wood stove. I don't know what the sliding piece is but it would make sense to me that a + would relate to more heat. It could be an air intake. Fire needs oxygen to burn so the more air you give it the hotter it will burn. Like wise by opening the damper it will increase airflow. Different woods burn hotter than others and any wood should be properly seasoned to maximize heat. If you know the make and model of your insert you might be able to find a manual online or go to a dealer and ask for help.

- Q:I'm making an energy efficient house for a science project, and all I can think of is the fact that the house works by taking energy from the sun.

- Make a rain barrel to reclaim rainwater for gardening. A graywater gadget permit you to recycle your bathe water. A composting rest room will relatively decrease decrease back on the water. in case you do not prefer to circulate that severe, use a flushless urinal.

- Q:The house I live in has fan-forced heating that consists of a fan blower and a gas heater. When the thermostat goes on, the fan and gas unit turns on. If the circut for the fan blower is cut off when the thermostat kicks on and the heat is supposed to be on, will the gas unit burn out because the fan isn't blowing?

- You may have a bad capacitor,many units use a dual purpose one that powers both the fan and the compressor. Much of the time when these fail the ends will pop up like a bad can of beans.Other times oil will run out of them. This is a silver round can type thing with wires coming out the top.It is in the electrical panel on your outside unit.Be care full not to touch the wires or terminals it can shock you.Pull the disconnect to the ac before servicing. Most ac or appliance shops have these ,cost 10 to 15 dollars.MORE INFO. If the drain was the problem you would not hear a hum as it would not send power to the outside unit.The capacitor terminals are marked with letters,make a drawing of what color wire goes where.Again remember to turn off or pull the disconnect,the box on the side of your house close to the a-c.unit.Use plastic handle needle nose pliers to remove wire's and do not touch the terminals on the capacitor after removing it can still shock you.Take this to the appliance shop and they will have one and can give advice.This is the most probable cause.The other less likely causes will require an hvac tech to repair.

- Q:For an outdoor pool, Is a swimming pool heat pump suitable in the uk for all year round swimming in terms of temperature and cost to run? I understand efficiency drops in colder weather.Thanks

- For an air to water heat pump, no, not really as a stand alone unit. Yes, if you add a gas fired heater as a back up for days that the outside air gets below 0C and you're sensible in keeping a solar blanket on the pool to minimize heat loss. As a general rule, when the air temp gets to -10 C, these units won't give you any heat at all or at least not enough to offset your pool's heat loss. If it's a geo thermal heat pump, your ability to scam heat gets better because you have a warmer source, but your costs also go up as their pretty expensive to buy and install. I've only ever seen this type in conjunction with household heating that has had the extra heat exchanger installed for the pool heat.

- Q:What is the material of construction used for the heat exchangers in an Ammonia Plant (high pressure and temperature conditions). Is there any useful websites that I can refer to??Thanks for your help,

- Construction of heat exchangers, boilers, and surface condenser tubes is mainly limited to copper, steel, stainless steel, and cast iron with exceptions such as the use of titanium in ultra high pressure vessel applications. To assure a proper tube joint, the tube wall must be reduced by a predetermined percentage dependent upon the material the tube is constructed of.[1]. For example, Tubing Material: Copper Cupro Nickel 8 - 10% Steel, Carbon Steel Admiralty Brass 7 - 8% Stainless Steel Titanium 4 - 5% Pneumatic or hydraulic torque rolling devices with an expander (consisting of a mandrel, cage with rolls, case assembly with a thrust collar) are used to expand the end of the tube so it seals against the tube sheet of the vessel. It is important to note that the type of tool has to be with paired not only with material but also the inner and outer dimensions of the tube as well. Thickness of the tube sheet (what each individual tube is inserted into) has to be taken into consideration during tube removal or installation procedures.

- Q:Don't understand this one at all, any help would be appreciated :)1) A heat exchanger is needed to heat a process stream from 300 degrees F to 425 degrees F. The heat will be supplied by steam on the shell side of the heat exchanger. Saturated steam is available at 600 psig ( approx. 490 degrees F, and delta H vap,600psig = 1699 kJ/kg). The heat capacity of the process stream is 3.0 kJ/kg degree C. The process stream flows at a rate of 10 kg/s. The overall heat-transfer coefficient is approx. 150 btu/hr ft squared degrees F.a) what flow rate of steam (mass/time) is needed for this heat exchanger?b) The boiling point of water with which we are most familiar with is 100 degrees C. How is it possible to have saturated steam at 490 degrees F?c) Estimate the required area of the heat exchanger in feet squared?will choose best answer as always!

- a] Do an energy balance. MCdeltaT on the process stream = condensation heat of the steam Take as basis 1 second MCdeltaT on the process stream = 10 x 3 x 125 x5/9 = 2083 kJ 2083/1699 = 1.226 kg steam per second b] Pressure is not atmospheric. c] Q' = U A deltaT A = Q'/U DeltaT You are going to need to convert some units first

- Q:My laptop gets heated up to 50 + .. do you think its normal ?

- You didnt list the model. Most laptops have fan speed regulated by temperature. If the fan doesn't kick in when the laptop gets hot, use a vacuum to clean the heat exchanger (no disassembly required), check the connections, or replace the fan (the latter solutions need to crack the box open). 50-60C is usually OK, but not for extended periods. over 65 is in the danger zone. 80+ guarantees shutdown or permanent damage.

- Q:Hi,Our Heat exchangers was designed for 365 PSI MAWP and Constructed as per ASME VIII Div 1. Originaly it was hydro tested at 522 PSI. Now our client request us to test it at 102 PSI of Air. We have a doubt of pressure testing due to stored energy of air in which our exchanger can withstand for all connection. The tube to tube sheet connection is only expansion (by rolling) and tubes inside 1quot; X 1.65 mm WT.If any one can help us mainly for Safety reason at this high pressure at 25 m high elevation at site, it would helpful for us.Thanks,

- You already tested the resistance of the exchanger at 522 psi, if it passed the test with no leaks (I mean 0) at a minimum of two hours, the equipment is ready, I pressume the customer may be concerned by the fact that air may leak through where water molecules could not, this is a valid concern but for this case considering that the initial test was done at almost 5 times more the pressure he now desires test, you can make it with no problems expected. It is better to find now any possible leak than to have to dissasembly the pipe-work and stop production after it is installed.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Spiral plate heat exchanger(Detachable)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords