Spiral plate heat exchanger(Non-Detachable)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The spiralplate heat exchanger is a high-efficient heat exchanging equipment used inalcohol, solvent, food ferment, pharmaceutical, petrochemical, refrigeration,organic chemistry, metallurgical industry, suitable for convection heattransfer of liquidtoliquid,gas to gas, gas to liquid.

The spiralplate heat exchanger comprises detachable and nondetachable exchanger. The spiral plate heat exchanger is made of carbon steel and stainless steel.

The argument list of carbon steel spiral plate heat exchanger

公称换热面积m2 | 通道间距m2 | 计算换热面积m2 | 流速1m/sec时处理量m3/h | 接管公称直径dg | 型 号 | 质 量(kg) I6T型 II6T型 | |

40 | 10 | 40.9 | 20.9 | 80 | I6.II6T40-0.6/1200-10 | 1730 | 2772 |

14 | 42.3 | 39.3 | 100 | I6.II6T40-0.8/1200-14 | 1843 | 2835 | |

18 | 44.9 | 63.5 | 125 | I6.II6T40-1.0/1200-18 | 2069 | 3061 | |

50 | 10 | 50.2 | 35.3 | 100 | I6.II6T50-1.0/1000-10 | 2334 | 3070 |

14 | 53.2 | 49.4 | 125 | I6.II6T40-1.0/1200-14 | 2408 | 3400 | |

18 | 54.0 | 76.3 | 125 | I6.II6T40-1.2/1200-18 | 2430 | 3422 | |

60 | 10 | 60.8 | 20.9 | 80 | I6.II6T60-0.6/1400-10 | 2673 | 4231 |

14 | 60.7 | 39.3 | 100 | I6.II6T60-0.8/1400-14 | 2750 | 4308 | |

18 | 61.6 | 63.5 | 125 | I6.II6T60-1.0/1400-18 | 3097 | 4655 | |

80 | 10 | 81.4 | 28.1 | 100 | I6.II6T60-1.0/1400-10 | 3365 | 4923 |

14 | 80.6 | 39.3 | 100 | I6.II6T80-0.8/1600-14 | 3445 | 5796 | |

18 | 82.0 | 63.5 | 125 | I6.II6T80-1.0/1600-18 | 3682 | 6033 | |

100 | 10 | 101.4 | 28.1 | 100 | I6.II6T100-1.0/1600-10 | 4250 | 6601 |

14 | 101.8 | 49.4 | 125 | I6.II6T100-1.0/1600-14 | 4390 | 6741 | |

18 | 108.2 | 76.3 | 125 | I6.II6T100-1.2/1600-18 | 4460 | 6811 | |

120 | 14 | 121.5 | 42.5 | 125 | I6.II6T120-1.2/1700-14 | 5130 | 7718 |

18 | 120.0 | 59.4 | 125 | I6.II6T120-1.2/1800-18 | 5250 | 7960 | |

130 | 14 | 130.5 | 32.5 | 125 | I6.II6T130-1.2/1800-14 | 5570 | 8280 |

18 | 131.0 | 49.4 | 125 | I6.II6T130-1.2/1900-18 | 5700 | 9005 | |

2.New Technology Description:

Five-ColumnThree-Effect Distillation Process

Our company designs and manufactures latestFive-ColumnThree-Effect Distillation equipment.This new process is promoted on the basisof traditional five-column differential-pressure column and mainly used forsuper-fine alcohol production.

The key of this process is the heatingmethods,the steam heats one column directly andtransfers theheat to other 4 columnsto achieve three-effect thermal couplingand energy-saving effects.

In terms of electricityefficiency, it can save 50% electricity and avoid the repairing ofcirculating pumps and also extend the working life of there-boilers.

Energy Consumption & Quality Indicator Table forSuper-fine Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗汽量Steam Consumption | t/t | 3.0 | 2.3 |

2 | 色度Colority | No. | 9.5 | 8 |

3 | 乙醇 Alcohol | %(v/v) | 95.5 | 96.5 |

4 | 硫酸试验Sulfuric Acid Test | No. | 70 | 9 |

5 | 醛(以乙醛计)Aldehyde (as acetaldehyde) | mg/l | 28 | 2 |

6 | 甲醇Methanol | mg/l | 18 | 3 |

7 | 正丙醇n-propyl alcohol | mg/l | 15 | 2 |

8 | 异丁醇+异戊醇Isobutanol+isoamylol | g/l | 27.5 | 2 |

9 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 9 |

10 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 16 |

11 | 不挥发物Nonvolatile matter | mg/l | 23 | 12 |

12 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.4 |

13 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 2 |

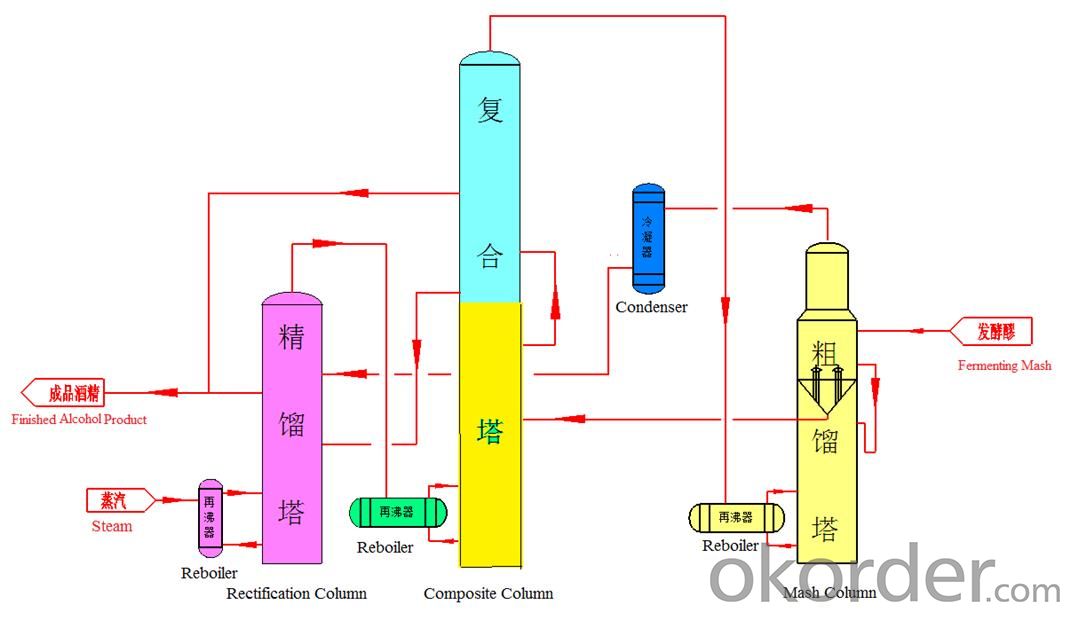

Double-Mash-Column Three-Effect Distillation Process

This process applies to the production ofgeneral-grade alcohol& fuel ethanol, and it was awarded Chinese nationalpatent, it is the onlysuccessfulapplicationof doublemash column & three-effect in the world,whichproduces general-grade alcohol.

This process is composed by mash column,rectification column and composite column. The composite column functions asmash column and rectification column.

The key of this process is the heatingmethods: the steam heats one column directly andtransfers the heat to other 2 columns to achieve three-effect thermal couplingand energy-saving effects.

The advantage of this process is energy-saving;itsaves over 40% steam

Energy Consumption & Quality Indicator Table for General-Grade Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗电量Electricity Consumption | kwh/t | 15 | 20 |

2 | 耗汽量Steam Consumption | t/t | 2.3 | 1.4 |

3 | 耗水量Water Consumption | t/t | 7 | 5 |

4 | 色度Colority | No. | 9.5 | 8 |

5 | 乙醇 Alcohol | %(v/v) | 95.5 | 95.5 |

6 | 硫酸试验Sulfuric Acid Test | No. | 70 | 55 |

7 | 醛Aldehyde (as acetaldehyde) | mg/l | 28 | 25 |

8 | 甲醇Methanol | mg/l | 100 | 55 |

9 | 正丙醇n-propyl alcohol | mg/l | 75 | 35 |

10 | 异丁醇+异戊醇Isobutanol+isoamylol | mg/l | 27.5 | 26 |

11 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 18 |

12 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 20 |

13 | 不挥发物Nonvolatile matter | mg/l | 23 | 21 |

14 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.5 |

15 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 3 |

3. Production Capability

1. Our company was established in the 1950s,designed and manufactured the first stainlesssteel distillation column in China.

2. Our company can produce6 full sets of equipment (including crushing section, liquefyingsaccharification section, fermentation section, distillation section and DDGSsection) in a

month.

3. Among 16 production workshops,3 workshops arefor mechanic manufacture, 5 workshops arefor manufacturing process, 8 workshopsare for assembling & welding.

4. We own advanced machining equipment and producttesting equipment.

4. Designed capability

1). We own Design License of SpecialEquipment D1 & D2 Class; Manufacture License of Special Equipment A2 Class;Design License of Special Equipment GC

Class.

2).Our company achieves more than 20 patentcertificates on distillation, DDGS, and other fields.

3). Ourcompany owns ASME certification, ISO 9001 Quality System Certification, ISO14001 Environmental Management System Certification & GB/T28001Occupational Health and Safety

Management System Certification

5. After-sales Service

1).Our company can provide a sophisticatedproduct after-sale service and can ensure the implementation, maintenance andcommission of projects.

2). We can reach the project site afterreceiving the user’s notification.

6.Package & Transport

- Q:This is for a science project, so make sure it is not too big or expensive.

- Build okorder /

- Q:the heat exchanger went out on our furnace at our summer home. can we still run the central air, or do we have to wait till our new furnace is instlled this fall?

- Yes you can still use the central air as there will be no negative effects because of the cracked heat exchanger...the only concern I would have is if it has a standing pilot(pilot burns all the time) I would turn off gas so there woud be no possibility of any carbon monoxide being pulled into the home by the air traveling past the heat exchanger...

- Q:i am tired of paying for hot water and lp gas. i am planning on bulding a shelf cantained box placing two 250 watt heat bulbs and a 40 gallon water tank in it what would happen

- I'd be glad to have LP Gas, or even Natural Gas, to have for my heat and hot water, at least based on the electric rates from our utility. If you want electric hot water, and your electric rates are cheap enough to compete with LP or natural gas, you need a hot water immersion storage tank, which will have two 240V 3KW heaters (usually with a stepped heating arrangement, where the top is heated to temperature first, then the bottom is allowed to heat. ) You can install a timer to control when it gets power to heat the water, to heat it only when you are scheduled to need it for laundry or dishes, or to heat on your cheap electric rate, for time-of-use billing. Depeding on code and practices, you could get point of use small volume electric water heaters as well.

- Q:I'm trying to get started on this problem but it looks like I don't have enough information to start it. I'll rewrite it:High pressure 20 degree Celsius water (no boiling) flows at 2 kg/s in a smooth 12 mm diameter pipe with pressurized super heated steam condensing on the outside in a heat exchanger. The steam maintains the pipe wall temperature at 140 degrees Celsius and the water flow is fully developed before entering the heat exchanger section that is 10 meters long. Determine Nu, h, exit temperature and total heat rate q in the heat exchanger. Assume water properties to be k = .613 W/m*K, cp = 4.179 kj/kg*K, u = 855x10^-6 kg/m*s, and Pr = 5.83.The water properties don't lead to any one temperature, and obviously determining T exit is essential in getting the rest of the information. I'm just unsure where exactly to start. I don't even have a value for density so I can't get velocity. Any hints would be appreciated.

- If you prefer the hard way, look up heat exchanger in your text. This is a simple case, since the temp outside is fixed. You can set up the integral and integrate to get the temp. Or, should be able to use same inlet and outlet temp to use standard heat exchanger calcs derived in your text. It all gets back to the log mean temperature difference. Good luck!

- Q:specify type of heat exchanger and fluid commonly used for a refrigerator?

- Specification is for the designer. But I can list them. A radiator (a pipe with fins on it) and some sort of freon like fluid (freon is no longer used) .

- Q:Ideas for experiments I could do in school that are related to keeping things hot or keeping things cool?

- Can you boil water in a baloon before it bursts? (Use a lighter to heat a mostly empty water balloon)

- Q:how heat transferred by phase change will affect the human comfort

- Perhaps this is where a chemist can help. The heat of evaporation (as water changes from liquid to gas) will cool the surface from which the water is evaporating. Perspiration cools the skin by this process. Of course if you are in a cold climate and are wet, the evaporation may cool the body dangerously. As you may know, phase change is the basis of air conditioning and refrigeration units. From Wikipedia: The refrigerant cycle consists of four essential elements to create a cooling effect. The system refrigerant starts its cycle in a gaseous state. The compressor pumps the refrigerant gas up to a high pressure and temperature. From there it enters a heat exchanger (sometimes called a condensing coil) where it loses energy (heat) to the outside. In the process the refrigerant condenses into a liquid. The liquid refrigerant is returned indoors to another heat exchanger (evaporating coil). A metering device allows the liquid to flow in at a low pressure at the proper rate. As the liquid refrigerant evaporates it aborbs energy (heat) from the inside air, returns to the compressor, and the cycle repeats. In the process, heat is absorbed from indoors, and transferred outdoors, resulting in cooling of the building.

- Q:I have a hot tub that contains approximately 500 gallons of water and would like to try heating it with a wood fire. I currently have a 20 pound propane tank that I have cut holes in that I was thinking I could place over the fire and have water run through it. Another thing I have seen is a big spiral of soft copper tube placed in the fire. How I understand it, it is simply the surface area that I care about. To heat the water in any sort of efficient way, do I need to go buy copper tube, or will the propane tank work. I understand that the water coming out of the copper spiral would be much hotter, but would they eventually heat the hot tub in about the same amount of time?

- As you probably know, there are several factors to account for, but let's talk about the major ones. Since you're going to use the same circulator pump with either the tank or the tubing, let's assume that you'd have roughly the same flow rate for each option. And let's say I also take your statement at face value: I understand that the water coming out of the copper spiral would be much hotter . . . The circulating water is the carrier for the heat calories from the fire to the tub. If it's much hotter coming out of the tubing than the tank, then, for a given amount of time, the tubing will carry many more calories than the tank solution would. So, roughly speaking, if the water output from the tubing is twice as hot as that from the tank, then it will be transporting twice as many calories per unit time, and the tub will heat up twice as fast--i.e. in ~ half the time. Regardless of the material you use, the ideal geometry for a heat exchanger will expose each molecule of the conducting fluid to the heat source as long as it takes to make them the same temperature before it leaves the exchanger. That's why automobile radiators are built like a fine honeycomb mesh--a molecule of water has a good chance of being exposed to the cooling air before it exits the radiator. That's where the surface area guideline comes in: The more the surface area of the exchanger (for a given flow rate), the more heat will be exchanged simply because of physical contact. In a sense, the tank you're proposing to use would be one of the worst exchangers, because very few of the water molecules would have direct contact with the wall of the tank before they exit the other end. The second factor is the thermal conductivity of the exchanger, which measures how fast heat flows through the material. Here copper, with a k = 400, has a big advantage over, say, steel, where k = 43. (See Source 1.) .

- Q:I FEEL THE LIQUIFIED PETROLIUM GAS BEEING PASSES THROUGH ONE HEAT EXCHANGER [ HEATED THROUGH RADIATOR PIPE LINE ] CAN GIVE BETTER BURNER EFFICIENCY. PLEASE CLEAR MY DOUBT.

- If you heat L.P.G. you raise the pressure. Is your gas regulator designed to correctly meter the fuel at the increased pressure? (There might well be some danger here.) What you propose will add the 'preheat' energy to the process, but as the L.P.G. already vaporises readily at S.T.P., you don't gain much. You might be better off preheating the combustion air than the fuel.

- Q:What properties should the connection tubing in a car radiator have? (Note that the tubing is not the fins). Here is a video of the connection tubing

- the only properties a tube should have is good heat transfer to the fins... The fins actually pull heat away from the tube and the air passing over them is how it cools the coolant in the radiator. The more fins per inch the better the cooling ability of a radiator... this is if I understand your question correctly

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Spiral plate heat exchanger(Non-Detachable)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords