Extra Heavy Duty Aluminum Foil Sheets 1mm Thick Factory Direct Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

Packaging & Shipping

Package: Standard seaworthy packing or as per request

Transports:Containler sizes:

20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High)

40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High)

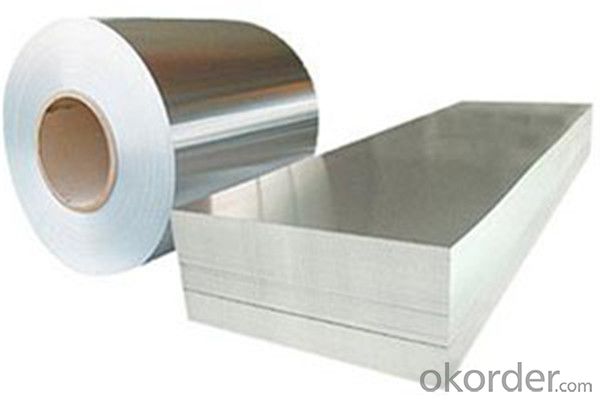

Specification of aluminum sheets 1mm thick:

Alloy | Temper | Thickness | Width |

3105,3005,3003,3103,3004,3104 | H12,H14,H18,H22,H122 | 1mm | 300-2100mm |

aluminum sheets 1mm thick application and character:

1.cookware, automotive and lighting industries.

2.Low anisotropy, which facilitates deep drawing.

3.Strong mechanical properties.

and moreover,the aluminum sheets 1mm thick prices is competitive.

Our Services

1 Customer and reputation first

2 Timely feedback

3 Low MOQ

4Timely delivery

5 Competitive price

6Different size can be supplyed as your request

7 Professional service of technical and shipping support

8More than 30 years experience in the cold and hot rolled sheet/coil/stri experience

Photos

- Q: Are aluminum sheets suitable for outdoor use?

- Yes, aluminum sheets are suitable for outdoor use. Aluminum is a durable and corrosion-resistant material that can withstand various weather conditions, making it ideal for outdoor applications.

- Q: A construction worker uses a steel tape to measure the length of an aluminum support column. If the measured length is 17.7 m when the temperature is 21.2°C, what is the measured length when the temperature rises to 35.4°C? (Note: Do not neglect the expansion of the steel tape. Give your answer to three decimal places.)I am really confused... Could someone solve it for me with a step-by-step explanation? Thank you so much.

- Aluminum cases offer better heat control than steel cases. Heat generating from the motherboard is absorbed by the case and then dissipated to the air. Aluminum dissipates heat better than steel. As for your question regarding ATX cases, have you tried using the barebone kits from Shuttle? Shuttle uses small form factor(i.e. small footprint). They are roughly the size of a shoe box.

- Q: What is the width and length of the aluminum sheets?

- The width and length of the aluminum sheets can vary depending on the specific product or manufacturer. It would be best to consult the product specifications or contact the manufacturer for accurate measurements.

- Q: Can the aluminum sheets be used for manufacturing automotive radiators?

- Yes, aluminum sheets can be used for manufacturing automotive radiators. Aluminum is a popular choice for automotive radiators due to its lightweight, excellent heat transfer properties, and corrosion resistance. Aluminum sheets can be easily formed into the required shape and size for radiator construction. Additionally, aluminum radiators offer better cooling efficiency compared to traditional copper radiators. Therefore, using aluminum sheets for manufacturing automotive radiators is a viable and advantageous option.

- Q: What are the different methods for joining aluminum sheets?

- There are several methods for joining aluminum sheets, including welding, riveting, adhesive bonding, and mechanical fastening. Welding involves melting and fusing the aluminum sheets together using heat, while riveting involves using metal fasteners to hold the sheets together. Adhesive bonding uses specialized adhesives to create a strong bond between the sheets, and mechanical fastening involves using screws, bolts, or other mechanical devices to secure the sheets together.

- Q: What are the advantages of using 101 aluminum sheets over other materials?

- One advantage of using 101 aluminum sheets is their high strength-to-weight ratio, making them lightweight yet durable. Additionally, aluminum is highly resistant to corrosion, making it suitable for outdoor applications without the need for additional protective coatings. Aluminum sheets are also easy to work with due to their malleability, allowing for various forming and fabrication processes. Lastly, aluminum is a highly recyclable material, making it an environmentally friendly choice.

- Q: What is the surface hardness of aluminum sheets?

- The surface hardness of aluminum sheets can vary depending on the alloy and treatment, but generally, aluminum has a relatively low surface hardness compared to other metals.

- Q: I'm buying a sword this afternoon for about 100 bucks i'm using it mainly to take pictures of and hang it on my wall. I looked up tips about buying swords and i think the sword i want is made out of aluminum. Could i use this sword as protection on an armed robber who would break into my house?

- Aluminum Sword

- Q: What specific tools or equipment are necessary for working with aluminum sheets?

- <p>Working with aluminum sheets typically requires a few specialized tools and equipment. These include a metal cutting saw for precise cuts, a metal file or sandpaper for smoothing edges, a metal shear for cutting, and a drill with metal bits for making holes. A roller or bending brake is useful for shaping the sheets, and a T-square or straight edge is important for marking straight lines. Safety equipment such as gloves, goggles, and a dust mask are also essential to protect against sharp edges and metal dust.</p>

- Q: Can aluminum sheets be waterjet cut?

- Yes, aluminum sheets can be waterjet cut. Waterjet cutting is a versatile method that uses a high-pressure stream of water mixed with an abrasive material to cut through various materials, including metals like aluminum. The waterjet cutting process is effective for aluminum because it does not generate heat, which can potentially deform or damage the metal. It also provides high precision and accuracy, allowing for intricate shapes and designs to be cut with ease. Waterjet cutting is commonly used in industries that require precise and clean cuts in aluminum sheets, such as aerospace, automotive, and manufacturing.

Send your message to us

Extra Heavy Duty Aluminum Foil Sheets 1mm Thick Factory Direct Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords