Re-boiler

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Re-boiler is ahigh-efficient heat exchanging equipment used in alcohol, solvent, foodferment, pharmaceutical, petrochemical, refrigeration, organic chemistry, metallurgicalindustry, suitable for convection heat transfer of liquidtoliquid,gas to gas,gas to liquid. Re-boiler is made of carbon steel and stainless steel.

2.New Technology Description:

Five-ColumnThree-Effect Distillation Process

Our company designs and manufactures latestFive-ColumnThree-Effect Distillation equipment.This new process is promoted on the basisof traditional five-column differential-pressure column and mainly used forsuper-fine alcohol production.

The key of this process is the heatingmethods,the steam heats one column directly andtransfers theheat to other 4 columnsto achieve three-effect thermal couplingand energy-saving effects.

In terms of electricityefficiency, it can save 50% electricity and avoid the repairing ofcirculating pumps and also extend the working life of there-boilers.

Energy Consumption & Quality Indicator Table forSuper-fine Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗汽量Steam Consumption | t/t | 3.0 | 2.3 |

2 | 色度Colority | No. | 9.5 | 8 |

3 | 乙醇 Alcohol | %(v/v) | 95.5 | 96.5 |

4 | 硫酸试验Sulfuric Acid Test | No. | 70 | 9 |

5 | 醛(以乙醛计)Aldehyde (as acetaldehyde) | mg/l | 28 | 2 |

6 | 甲醇Methanol | mg/l | 18 | 3 |

7 | 正丙醇n-propyl alcohol | mg/l | 15 | 2 |

8 | 异丁醇+异戊醇Isobutanol+isoamylol | g/l | 27.5 | 2 |

9 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 9 |

10 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 16 |

11 | 不挥发物Nonvolatile matter | mg/l | 23 | 12 |

12 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.4 |

13 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 2 |

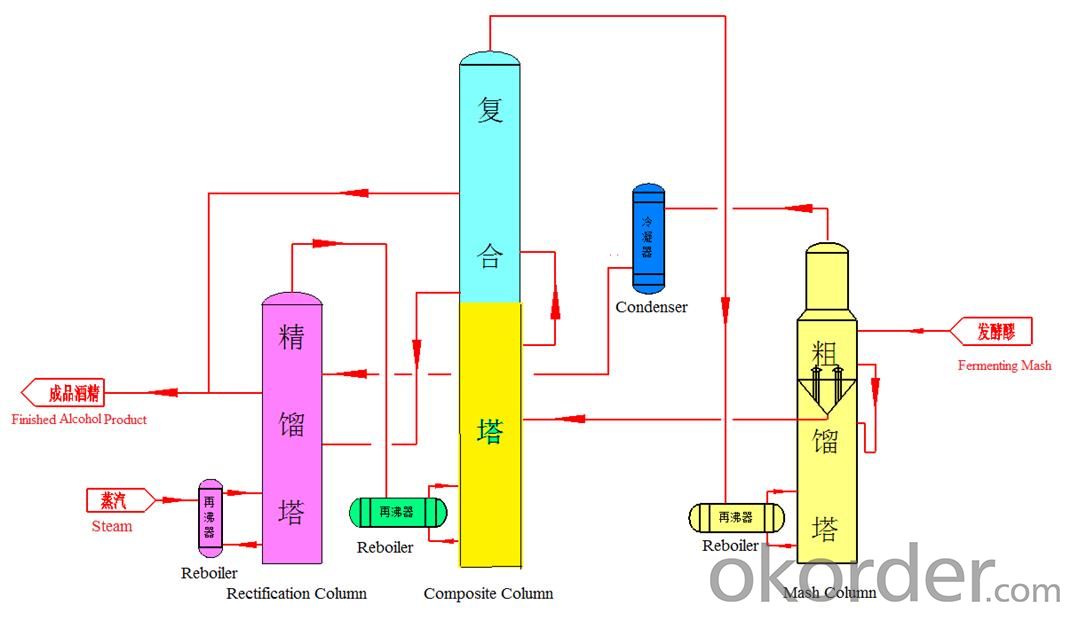

Double-Mash-Column Three-Effect DistillationProcess

This process applies to the production ofgeneral-grade alcohol& fuel ethanol, and it was awarded Chinese nationalpatent, it is the onlysuccessfulapplicationof doublemash column & three-effect in the world,whichproduces general-grade alcohol.

This process is composed by mash column,rectification column and composite column. The composite column functions asmash column and rectification column.

The key of this process is the heatingmethods: the steam heats one column directly andtransfers the heat to other 2 columns to achieve three-effect thermal couplingand energy-saving effects.

The advantage of this process is energy-saving;itsaves over 40% steam

Energy Consumption & Quality Indicator Table for General-Grade Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗电量Electricity Consumption | kwh/t | 15 | 20 |

2 | 耗汽量Steam Consumption | t/t | 2.3 | 1.4 |

3 | 耗水量Water Consumption | t/t | 7 | 5 |

4 | 色度Colority | No. | 9.5 | 8 |

5 | 乙醇 Alcohol | %(v/v) | 95.5 | 95.5 |

6 | 硫酸试验Sulfuric Acid Test | No. | 70 | 55 |

7 | 醛Aldehyde (as acetaldehyde) | mg/l | 28 | 25 |

8 | 甲醇Methanol | mg/l | 100 | 55 |

9 | 正丙醇n-propyl alcohol | mg/l | 75 | 35 |

10 | 异丁醇+异戊醇Isobutanol+isoamylol | mg/l | 27.5 | 26 |

11 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 18 |

12 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 20 |

13 | 不挥发物Nonvolatile matter | mg/l | 23 | 21 |

14 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.5 |

15 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 3 |

3. Production Capability

1. Our company was established in the 1950s,designed and manufactured the first stainlesssteel distillation column in China.

2. Our company can produce6 full sets of equipment (including crushing section, liquefyingsaccharification section, fermentation section, distillation section and DDGSsection) in a

month.

3. Among 16 production workshops,3 workshops arefor mechanic manufacture, 5 workshops arefor manufacturing process, 8 workshopsare for assembling & welding.

Weown advanced machining equipment and product testing equipment.

4. Designed capability

1). We own Design License of SpecialEquipment D1 & D2 Class; Manufacture License of Special Equipment A2 Class;Design License of Special Equipment GC

Class.

2).Our company achieves more than 20 patentcertificates on distillation, DDGS, and other fields.

3). Ourcompany owns ASME certification, ISO 9001 Quality System Certification, ISO14001 Environmental Management System Certification & GB/T28001Occupational Health and Safety Management System Certification

5. After-sales Service

1).Our company can provide a sophisticatedproduct after-sale service and can ensure the implementation, maintenance andcommission of projects.

2). We can reach the project site afterreceiving the user’s notification.

6.Package & Transport

- Q:I know the theoretical heat pump efficiency, but I need to know the individual efficiencies of the components such as the quot;motorquot; that moves the refrigerant and the electrical transmission efficiency. I can't find this info on the web. If you can direct me to a source as well as explain it here, I would be grateful.

- The overall efficiency is totally dependant on the material to be heated or cooled and the source or sink that provides the thermal difference that the heat pump uses. Factors like the thickness of the pipes that go into deep thermal wells are dependant on the corrosion potential of the source. Thin pipes transfer quicker with higher efficiency. Thick last longer. A motor that transfers fluid down a few hundred feet into a water well will be rated differently from a pump that has to go down a thousand feeet. A local beer distributer had two water wells put in that included cooling plumbing for his refrigerent system. His electric bill was cut in half. Pumps will have efficiency rating listed for many applications. Heat exchangers will have ratings based on speed, contact area, temperature differences, etc. No wonder you are having trouble finding a deffinite answer.

- Q:My furnace starts and stops randomly until the 4th or the 5th try. It does this very regularly and had a technician come in ever so often and the problem still continues. We would always have to go and shut it off and restart it again to have heat in the house. Good thing I have maintenance plan. But are they really helping me? They already did everything that's needed which covers the warranty maintenance plan. Now I'm being told it needs a heat exchanger replacement at a cost of $860. My wife works for a construction company and had a contractor come in and did a diagnostic on the furnace and found out the gas valve intake did not meet it's requirement after adjusting it the problem was solved. Would I still be having problems later on or was this just a matter of being sucked for $860 from the company that bills me for the heating? I have not gone to restart the machine so far.

- my case is the opposite my furnace stays on for too long and shuts off but only for 1 minute had it check already couldn't find anything wrong what is the problem---on 10 minutes off 1 minute.thanks

- Q:I'm trying to get started on this problem but it looks like I don't have enough information to start it. I'll rewrite it:High pressure 20 degree Celsius water (no boiling) flows at 2 kg/s in a smooth 12 mm diameter pipe with pressurized super heated steam condensing on the outside in a heat exchanger. The steam maintains the pipe wall temperature at 140 degrees Celsius and the water flow is fully developed before entering the heat exchanger section that is 10 meters long. Determine Nu, h, exit temperature and total heat rate q in the heat exchanger. Assume water properties to be k = .613 W/m*K, cp = 4.179 kj/kg*K, u = 855x10^-6 kg/m*s, and Pr = 5.83.The water properties don't lead to any one temperature, and obviously determining T exit is essential in getting the rest of the information. I'm just unsure where exactly to start. I don't even have a value for density so I can't get velocity. Any hints would be appreciated.

- If you prefer the hard way, look up heat exchanger in your text. This is a simple case, since the temp outside is fixed. You can set up the integral and integrate to get the temp. Or, should be able to use same inlet and outlet temp to use standard heat exchanger calcs derived in your text. It all gets back to the log mean temperature difference. Good luck!

- Q:Can citric acid remove carbonates, what should be the concentration of solution?

- The most effective and economical way of removing carbonate deposits is by mechanical, chemical reagents like acids seems to be corrosive and uneconomical not to mention the environmental impact.

- Q:the coolant given will also be just normal running water (tap water)... ntn else sholud be used !!!!!!! simple construction also... pl give me some sites where i can find details fr making it..

- A length of Cu tubing. Connect one end to the source of hot water, the other end to where you want the cooled water to come out. Then place a loop of the tube in a bucket of cold water. Depending on how hot the hot water is, how long your copper tube is, and how fast (mass flow rate) the hot water is going thru the tube, you will be able to cool the hot water down to, at the best, the temperature of the water in the bucket.

- Q:In a well-insulated heat exchanger, the overall heat transfer coefficient is 6.6 kW/m2.°C and the total effective heat transfer area is 1.5 m2. The temperature difference between the inlet and exit of the minimum fluid (the fluid with minimum thermal capacity) is 60 ?C and the corrected LMTD of the heat exchanger is 30 °C. Which one about the thermal capacity of the maximum fluid (the fluid with the maximum thermal capacity) is correct?A.The given information is not enough to answer this questionB. Cmax = 4950 W/°CC .Cmax lt; 4950 W/°CD. Cmax gt; 4950 W/°C

- I assume the temperature difference for minimum fluid is for cold or hot stream only. Not the difference between them (the cold and hot). U = 6.6 kW/m^2.°C A = 1.5 m^2 ΔT_min = 60 deg. C LMTD = 30 deg. C Q = U*A*LMTD Q = 6.6*1.5*30 Q = 297 kW Heat transfer from cold/hot fluid. Q = Cp_min*ΔT_min Cp_min = 4950 W/°C With, LMTD = ΔT2 - ΔT1 / ln(ΔT2/ΔT1) 30 = ΔT2 - ΔT1 / ln(ΔT2/ΔT1) We have only one equation, with two unknows, temperatur inlet and outlet for maximum fluid, thus it can't be solved. Cp_,max = Q/ΔT_max Cp_max can't be solved because ΔT_max is unknown. So the answer may be A or D. A. The given information is not enough to answer this question D. Cmax > 4950 W/°C However if one just need for range capacity, then the answer is D.

- Q:If I heat my main level with a gas fireplace and run my heat pump in fan-on mode, do you think this will heat my basement also? trying to save some money, power bills are crazy this year.

- Don't forget. Unless you have a direct outside air supply to the fireplace, you are sending a lot of house air right up the chimney and sucking cold air into the house from any small cracks around windows and doors. Fireplaces need go be designed very carefully to provide a true net positive addition to your home's heating. They need an outside combustion air supply, tight glass doors on the front and a good heat exchanger built in with fan to be efficient. Only if you have air registers or an open air return in the basement will you get any benefit from the circulating fan.

- Q:raw water temp 18 0c, req range of dm water temp is 25 0c to 35 0c. raw water pump having 500 lpm, dm water pump having 150 lpm

- What is the start temp of the DM water? We need to know that so we can determine the exchanger duty to start the calculations.

- Q:It is for grade 12 physics on heat exchange between materials.

- For another theme, what is the best way to use solar power? Heating water? Solar thermal power generation?

- Q:I have an Comfortmaker m/n GUK075N12C1 90% high efficiency forced air furnace that is approx 10 years old. It has leaked water for 2 years now. I have cleaned out the condensate trap and replaced the tubing hoping that this would remedy the situation. My HVAC contractor spent 2 hours taking apart and resealing the front intake fan assembly. When this did not work he suggested that the lower heat exchanger may be cracked and suggested replacement. I know the unit has had a hard life with the previous owner and is also in a damp basement. Since the unit has been leaking water rust is now present both internally and externally. Should I replace or pay someone else $90+/hr to look at it?

- I work for a heating company and i would recommend replacement...otherwise you are going to start spending more and more in repairs... if the heat exchanger is cracked, its a MUST to replace it....since you would be letting Carbon Monoxide into your home... plus now, there are more efficient and comfortable furnaces that may even lower your bills :) You don't have to get too fancy, depends on how long you want to stay in your home....but there are models with variable speeds and 2 stages that are pretty cool! 10 years isn't too bad, but its def. close to a furnace's max. life. Good Luck!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Re-boiler

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords