CNC Ball Grinder KP7060 with Syntec system

- Loading Port:

- NINGBO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

The lathe is controlled by CNC system; the CNC function of complete machine is realized by all-digital alternating current servo driver's controlingover two servo motors.The horizontal traverse X axis and longitudinaltraverse Z axis of platen are driven by servo motors. They have non-intermittent motion through direct-connection ball screw of fine coupling, to make the whole grinding process realize automatic processing according to program. In this way one person can manage multiple machine: labor costs can be reduced for users and productivity can be enhanced

Grinding ball materials: A105、2Cr13、304、304L、316、316L、LF2、F51、17-4PH、Monel、 ENP、Chrome platino、Tunosten Carbide、Stelite、Inconel and ceramic ball valves etc

System option:Syntec

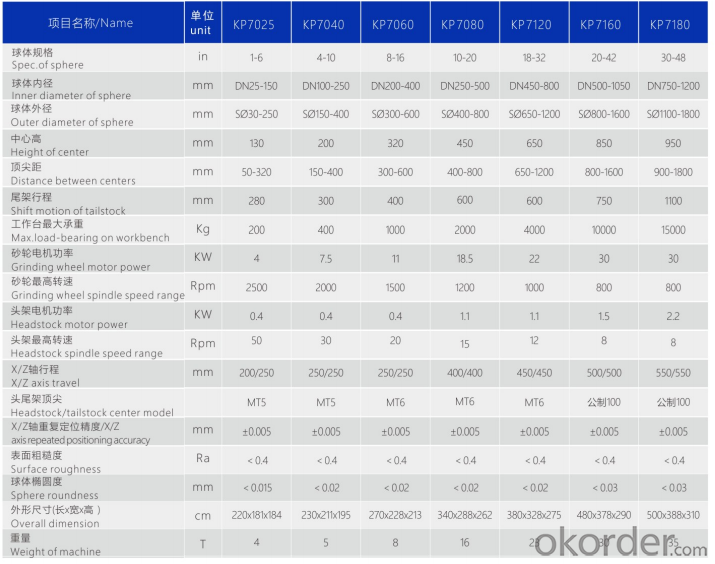

Technical Parameter

Package

Application Area

Suitable for precision machining of large workpieces such as aerospace, automobiles, textile , molds, packaging machinery, mining equipment, etc. It can automatically complete complex machining processes such as boring, drilling, milling, tapping, etc.

Global Sales Market

Cooperative Clients

Q&A

Q1. Where is your factory located?

A : Our factory is located in Taizhou City, Zhejiang Province, China.

Q2. Are you produce peeling/ polishing machine's specific parameters according to the samples?

A: Yes, we produce the machine you want by your samples or technical drawings.

Q3. What is your sample service?

A: We can supply the sample testing which client want to produce if we have ready machine in stock.

Q4. What is your MOQ of your machine?

A: Normally our MOQ is 1 set.

Q5. Do you test all your machine before delivery?

A: Yes, we have 100% test before delivery.

Q6: What is the payment term?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q7: What is the normal lead time?

A: 45-60 days after we receive the deposit.

Q8: Guarantee Period?

A: 1 year. During the guarantee period, we guarantee to solve all problems may occur due to machine's quality or wrong design, and to provide all necessary spare parts for repair. We can send the technician to customer's factory if problem is serious and can't be solved by the customer.

- Q:What is the machining center? The

- 2, can be processed ordinary machine can not be processed or difficult to process the parts, such as the mathematical model described in the complex curve parts and three-dimensional surface parts of the surface;

- Q:Processing center processing oblique oval

- For example, your circular tolerance to be controlled in the 2 silk, then you use the cutter is extremely difficult to milling out, because the milling circle is theoretically irregular circle

- Q:The difference between the heart and the milling machine, I feel like almost! Is not the diameter of the processing machine to be smaller?

- This is not directly related to the diameter of the work.

- Q:Machining center in the G98, G99 What does it mean?

- You can come to our school to participate in the training center training, we can tailor your course, to ensure that you learn to learn, through research, access to higher employment opportunities and pay!

- Q:The Advantages and Disadvantages of Carving Machine and Machining Center

- Engraving machine: its spindle speed is high for small tool processing, torque is relatively small, focusing on "carving" function, such as wood (specifically wood processing known as wood carving machine), two-color plate, acrylic plate and other hardness is not high plate,

- Q:CNC machining center g51 scaling instructions. Suppose I'm a 20-round round Now I want to shrink to 10 rounds how to use this command. Such as

- Instruction format: G51 X____ Y____ Z____ P____

- Q:How is the I J K in the machining center?

- K - the coordinate of the center of the arc relative to the starting point of the Z axis

- Q:Vertical machining center lubrication system

- Vertical processing center lubrication system Simply put, is to separate the supply of lubricating oil and compressed air mixed and the formation of turbulent oil and gas mixed flow and then sent to the processing center spindle

- Q:CNC machining center alarm 1005

- The alarm shows 1005 C-OOL Box I suspect that there is a problem with the price of the wind is still Vulian show is 0 26.0 after the alarm shows is E5

- Q:Will fanuc processing center length compensation how to use? Can you give an example to explain!

- Such as the use of the workpiece workpiece coordinate system G54 X Y knife does not introduce the Z data to pay special attention

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CNC Ball Grinder KP7060 with Syntec system

- Loading Port:

- NINGBO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches