Reinforced Steel Precast Concrete Purline Molds

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Reinforced Steel Precast Concrete Purline Molds

1. Structure of Reinforced Steel Precast Concrete Purline Molds:

Reinforced Steel Precast Concrete Purline Molds is our special developed products as results of our engineers research, with which 60%steel material will be saved compared with traditional revolving die method .Efficiency can be improved 3 to 5 times compared with conical die method, these machine are easy for operation and convenient for maintenance, products from these machines are in good quality, smooth appearance and accurate in size.

2. Main Features of Reinforced Steel Precast Concrete Purline Molds:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

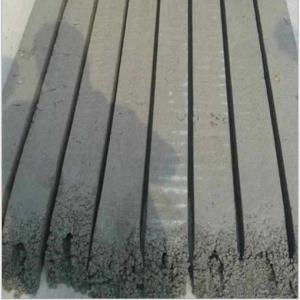

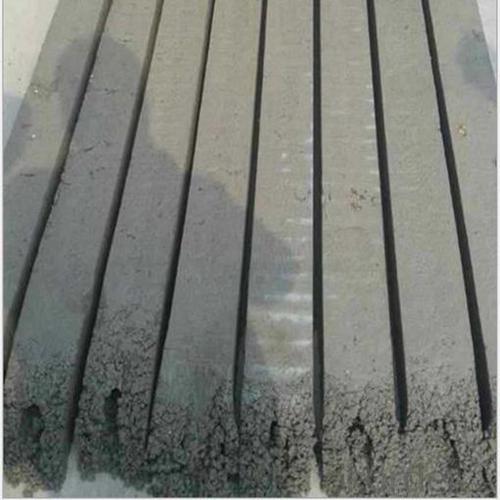

3. Reinforced Steel Precast Concrete Purline Molds Images:

4. Reinforced Steel Precast Concrete Purline Molds Specification:

Product name | Type | Productivity | Hole number |

Concrete purline machine | 60*120*140* | 1.3-1.5m/min | 4 |

Concrete purline machine | 60*130*150*4 | 1.3-1.5m/min | 4 |

Concrete purline machine | 60*140*160*4 | 1.3-1.5m/min | 4 |

Concrete purline machine | 70*150*170*2 | 1.3-1.5m/min | 2 |

Concrete purline machine | 80*160*180*2 | 1.3-1.5m/min | 2 |

Concrete purline machine | 60*110*130*4 | 1.3-1.5m/min | 4 |

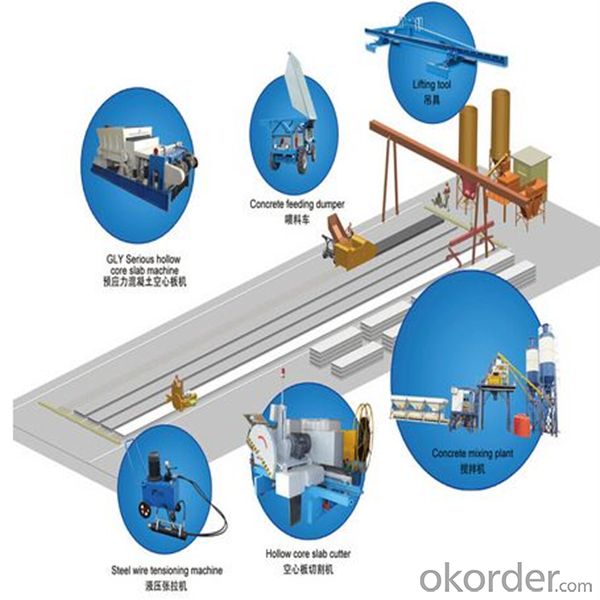

Production Line Layout

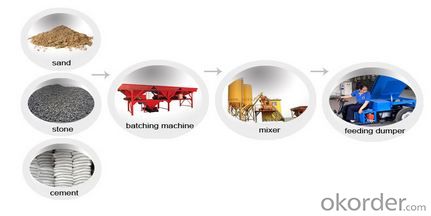

Production Process

Rebar tensioning

Raw materials preparing

Molding

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. Customers from All Over The World

7. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

8. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

9. Our Service:

• We supply the technical supporting all the time.

• We supply one year warranty for whole machine.

• We supply free quick wear parts.

• We supply low charge continue maintenance when warranty is expired.

• We supply free training to end-users

- Q:if not how much would you pay for one if i did it (NOT)

- If you did it, the chances of reliable accuracy would be small, no matter how good you are.

- Q:Machinery was purchased for $51,000 on January 1, 2009. Freight charges amounted to $2,100 and there was a cost of $6,000 for building a foundation and installing the machinery. It is estimated that the machinery will have a $9,000 salvage value at the end of its 5-year useful life. What is the amount of accumulated depreciation at December 31, 2010, if the straight-line method of depreciation is used? $10,020. $8,580. $17,160. $20,040.

- $20,040: (51,000+2,100+6,000-9,000) / 5 = 10,020 per year 2009 - 10,020 2010 - 10,020 Total = $20,040

- Q:Each part adds to the length of each item. There are 2 parts with a length of 3/4 inches, and 3 parts with a length of 1 5/8.What is the total length of machincery?a) 1 1/4 in b) 4 7/8 in c)5 1/8 in d)6 3/8in

- D

- Q:what rate of depreciation on new machineries purchase?

- The maximum section 179 deduction you can elect for property you placed in service in 2006 is increased to $108,000 for quali?fied section 179 property. This limit is reduced by the amount by which the cost of section 179 property placed in service during the tax year exceeds $430,000. Assuming you bought this equipment and it was placed into service in 2006, you dont have to capitalize it and depreciate it. You can elect to expense the equipment up to $108,000. This limitation gets reduced dollar for dollar for the amount of equipment placed into service in 2006 that exceeds $430,000.

- Q:where can i get the list sugar plant machinery with the details & market value?

- Ask Dole Pineapple or look on the US Dept Us Agriculture website or google

- Q:Any manufacturers or suppliers give the details of above matter in India

- Here's okorder /

- Q:why on ship machinery's are installed forward-aft & not port starboard?

- I guess it helps if the axis of the propulsion machine is in line with the propeller shaft so it doesn't need some sort of right angle drive.

- Q:i need help w/ a science question lol....:] help please! thnx! o and also, the 1st question is more important, but if u know this one, it would help too: How is friction a factor in outer space?

- OK, I'm thinking about the situations you mention........now, what exactly was the question.......?! Nothing, including friction, is a (factor...?) in 'outer space'. Reason: there's nothing there.

- Q:what do companies benefit from when upgrading machinery?

- Depends what you mean by upgrading. A business can upgrade existing machinery to perform faster, better, etc or they can purchase a new machine to replace an older one. With upgrading the business is looking at increasing output, reducing operating costs and improving the efficiency of the machine. A new machine will potentially return less downtime due to breakdowns, but may have teething troubles whilst it settles in. New machinery will have costs involved, not only the purchase cost, but cost of spares, cost of training to operate and maintain, and depreciation. Hope this helps

- Q:Bq: have you read elfen liedBq2: favorite quote from a book

- Kyrie- Mr. Mister Bq: No. Bq2: And in its sky was such a sun as no opium eater could have imagined in his wildest dreams. Too hot to be white, it was a searing ghost at the frontiers of the ultraviolet. (Childhood's End-Arthur C. Clarke-Chapter 16-The Last Generation)

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Reinforced Steel Precast Concrete Purline Molds

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords