Automatic Concrete Purline Lintel Making Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Automatic Concrete Purline Lintel Making Machine

1. Structure of Automatic Concrete Purline Lintel Making Machine:

Automatic Concrete Purline Lintel Making Machine is our special developed products as results of our engineers research, with which 60%steel material will be saved compared with traditional revolving die method .Efficiency can be improved 3 to 5 times compared with conical die method, these machine are easy for operation and convenient for maintenance, products from these machines are in good quality, smooth appearance and accurate in size.

2. Main Features of Automatic Concrete Purline Lintel Making Machine:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

3. Automatic Concrete Purline Lintel Making Machine Images:

4. Automatic Concrete Purline Lintel Making Machine Specification:

Product name | Type | Productivity | Hole number |

Concrete purline machine | 60*120*140* | 1.3-1.5m/min | 4 |

Concrete purline machine | 60*130*150*4 | 1.3-1.5m/min | 4 |

Concrete purline machine | 60*140*160*4 | 1.3-1.5m/min | 4 |

Concrete purline machine | 70*150*170*2 | 1.3-1.5m/min | 2 |

Concrete purline machine | 80*160*180*2 | 1.3-1.5m/min | 2 |

Concrete purline machine | 60*110*130*4 | 1.3-1.5m/min | 4 |

Model no. | No. of holes | Dia. | No. and dia. of wires | Electric motor power(kw) | Vibrator Motor Power(kw) | Total Power (kw) | Max. span | Molding Speed(m/min) | Overall dimension (mm) | Weight (kg) |

60X120X140X4 | 1 | 30 | 5/5 | 4 | 1.5 | 5.5 | 3.5 | 1.3-1.5 | 2250×900×850 | 1000 |

60X130X150X4 | 1 | 30 | 6/5 | 4 | 1.5 | 5.5 | 4 | 1.3-1.5 | 2250×900×850 | 1000 |

70X140X160X4 | 1 | 30 | 8/5 | 4 | 1.5 | 5.5 | 4.5 | 1.3-1.5 | 2250×900×850 | 1050 |

70X150X170X2 | 1 | 30 | 8/5 | 3 | 1.5 | 4.5 | 4.7 | 1.3-1.5 | 2250×900×850 | 750 |

60X110X130X4 | 1 | 30 | 6/5 | 4 | 1.5 | 5.5 | 3.5 | 1.3-1.5 | 2250×900×850 | 950 |

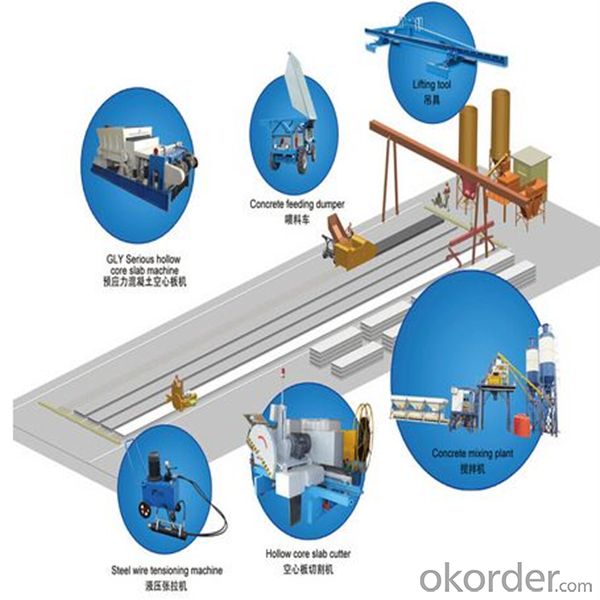

Production Line Layout

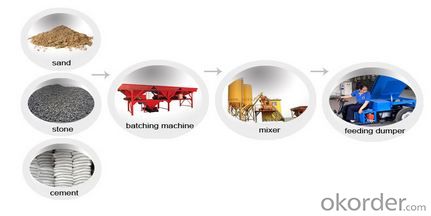

Production Process

Rebar tensioning

Raw materials preparing

Molding

Certificates

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. Customers from All Over The World

7. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

8. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

9. Our Service:

• We supply the technical supporting all the time.

• We supply one year warranty for whole machine.

• We supply free quick wear parts.

• We supply low charge continue maintenance when warranty is expired.

• We supply free training to end-users

- Q:I'm specifically looking for training on heavy machinery such as bulldozers, backhoes cranes etc. The courses are given in montreal but there's a 10 year wait. If you know of any sort of training course of the sort in the 613 area code, please let me know. Thanks

- Try okorder /

- Q:I need a list of machinery, and the methods of how trees are cut down. Do they only use chainsaws? or are there bigger machines that cut faster and better? plz answer, im trying to create an accurate scene in a painting ( im in the planing stages).

- I'm okorder /

- Q:what rate of depreciation on new machineries purchase?

- The maximum section 179 deduction you can elect for property you placed in service in 2006 is increased to $108,000 for quali?fied section 179 property. This limit is reduced by the amount by which the cost of section 179 property placed in service during the tax year exceeds $430,000. Assuming you bought this equipment and it was placed into service in 2006, you dont have to capitalize it and depreciate it. You can elect to expense the equipment up to $108,000. This limitation gets reduced dollar for dollar for the amount of equipment placed into service in 2006 that exceeds $430,000.

- Q:What kind of materials can EDM machine

- Theoretically, any conductive material can be machined with a wire EDM machine.

- Q:what is difference between machinery and equipment?

- Weird things happen when machinery is rotating has very high(turbo) speeds but both are similar but rotating equipment would probably be the foundation to turbo machinery.

- Q:Like only 90 or 120 degrees, but it's precisely controlled.Thanks!

- The steering on your car.

- Q:What are the main considerations when choosing mechanical parts?

- Heat treatment conditions, there is no heat treatment conditions and no heat treatment conditions of the election of different materials; the weight requirements, often mentioned in the hands of the parts require light, to meet the mechanical strength conditions can choose a small proportion of material, life requirements

- Q:Do engineering technicians get to invent and patent ideas within large companies, or is this typically reserved for the mechanical engineers?

- Mostly, engineer's are problem solver's. In the case of mechanical engineers. you are partly correct. They are given a problem, like they need a machine that can build a part or perform some action, but has to fit within certin peramiters. So the engineer has to figure out how to make it work. But this is only a small part of what an engineer does.

- Q:I found one in italy. that says our machinery for beverages:-filling,-dosing, -rinsing machines, -labeling, -bending, -capping machines,-packaging and conditioning machinery, -automatic corking machines,-sterilizations sysytems i wanna know what these ^ mean to explain each of them basically and their functions for the beverage machinery.. plz help !!!!!!!!!!!!

- hh

- Q:Do Machinery Repairman (MR) in navy get assigned to subs?

- Submarines are voluntary.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Automatic Concrete Purline Lintel Making Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords